From advanced inspection systems to data-driven monitoring, innovation is redefining how the food industry protects consumers and ensures compliance.

Food is a fundamental part of human survival, connecting cultures, families, and communities across the globe. It is a resource we trust, share, and rely on to nourish both body and mind. Yet the food we consume today often carries invisible threats and silent risks that can compromise our health. Every year, more than 600 million people suffer from foodborne illnesses, resulting in an estimated 420,000 deaths worldwide, according to the World Health Organization.

Why Food Safety Matters

Today, the challenges of food safety are intensifying, driven by the rapid globalization of food systems and the immense scale of production. As food moves through complex supply chains, it passes though diverse environments, regulatory frameworks, and handling practices . Each transfer point increases the risk of contamination. From farm to fork, this contamination can take many forms, including chemical residues, microbiological hazards, and physical impurities. This means companies involved in food production face ongoing challenges. Cleaning and sanitation are labor-intensive and reduce output, equipment can be difficult to maintain, and audits demand detailed, traceable data.

Mike Pipe is the Head of Product Inspection UK at Mettler Toledo, a Swiss multinational providing cutting-edge food safety solutions. According to him,

“Food safety and hygiene are vital for protecting consumers, preventing cross-contamination, and maintaining the brand reputation of companies in the food industry, while ensuring strict global standards and retailer requirements are met at the same time. Strategic investment in product inspection technologies at critical control points is essential to achieve the right balance of safety, efficiency, and compliance.”

Read also

Contamination Detection

Innovative technologies are transforming food safety by enabling faster detection, smarter prevention, and greater transparency across the supply chain. A key focus area is contamination detection, which lies at the heart of food safety. Detection technologies are designed to identify and remove potentially harmful materials before they reach the consumer, providing manufacturers with a strong first line of defence. Methods for detecting physical contaminants vary depending on where inspection equipment is positioned along the production line, ensuring targeted and effective protection at every stage.

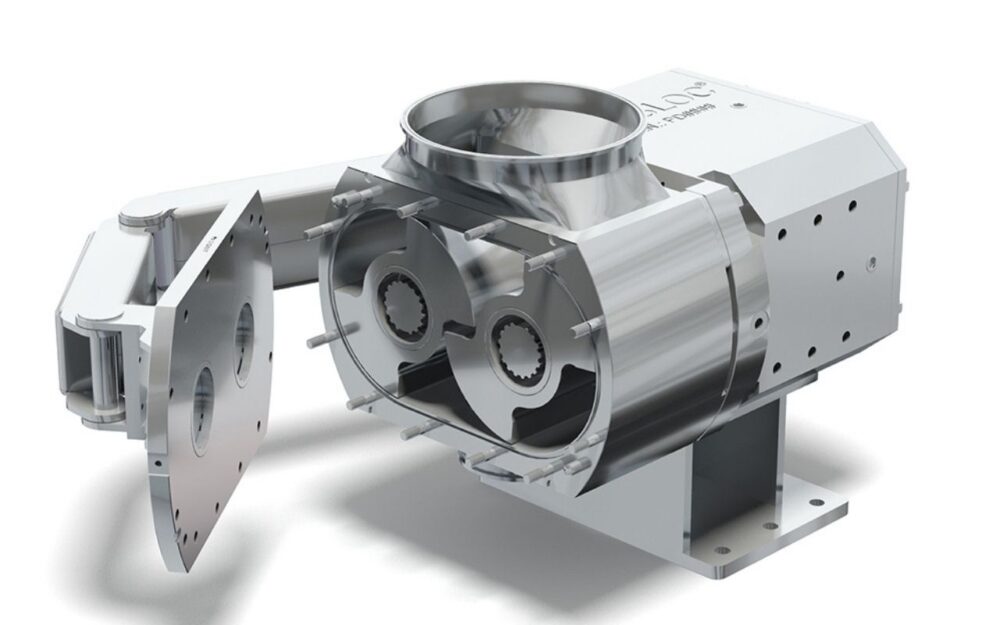

Metal detection remains a cornerstone technology, with modern systems — such as those offered by Mettler Toledo — capable of identifying ferrous, non-ferrous, and stainless-steel contaminants with diameters as small as 0.3 mm across a wide range of food products. Using multi-simultaneous frequency and advanced signal processing, these detectors boast outstanding sensitivity while reducing false rejects —an important factor in cutting waste and protecting profitability.

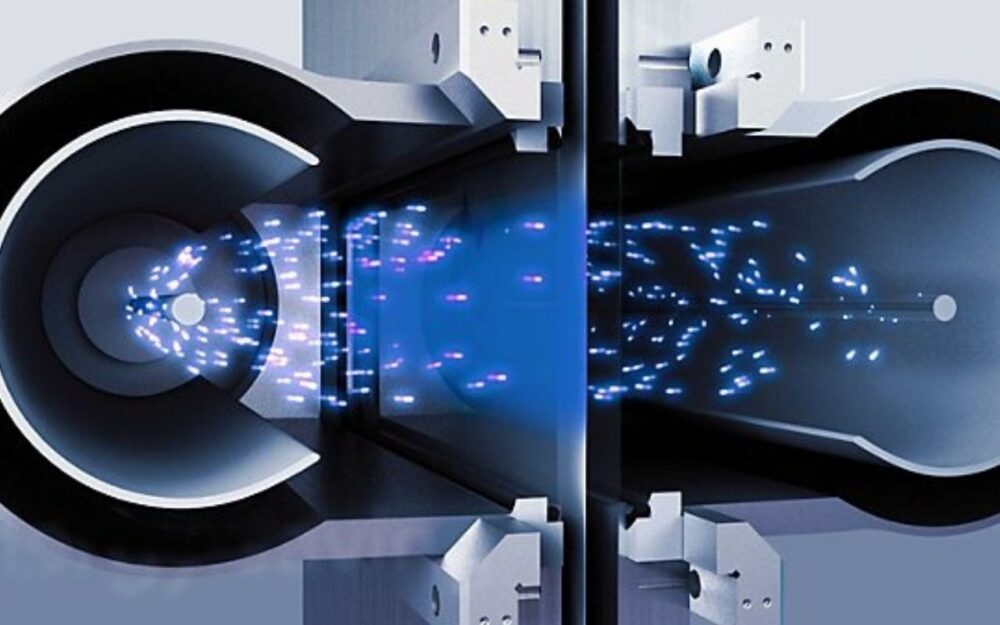

X-ray inspection goes even further by screening food products for metal as well as other foreign material types, such as glass, stone, calcified bone, and certain plastics.

“Beyond contamination control, X-ray systems provide powerful quality assurance functions, including checking fill levels, spotting broken or missing components, and verifying seal integrity,” says Mike Pipe. “Combining contamination detection with quality checks means manufacturers can control both safety and product integrity in a single step.”

X-ray detection technology in food safety is currently advancing through higher-resolution imaging, AI-powered algorithms, and dual-energy systems, which use two different X-ray energy levels for enhanced material discrimination. The IX-G2 Series X-ray Inspection System from Japanese multinational Ishida, for example, features a dual-energy sensor and self-learning image processing to enhance contaminant detection — particularly for low-density foreign objects such as bone fragments.

Weight Checking

A checkweigher is a device, typically integrated into a production line, that weighs products as they move, ensuring they fall within pre-set weight limits and automatically rejecting those that are over- or underweight. The latest checkweighers, such as those from Mettler Toledo, support food safety by preventing incorrect nutritional information, avoiding regulatory fines for underfilled products, and keeping non-compliant items from reaching consumers. When combined with feedback controls, they also help optimize filling processes, directly boosting productivity. They are often complemented by vision inspection systems, which validate label accuracy, barcodes, artwork, and packaging condition — an increasingly important step as stricter labelling regulations come into effect.

“Precision weighing and contaminant detection technologies are increasingly combined in integrated inspection systems, which reduce equipment footprint, simplify cleaning routines, and streamline operator training,” says Mike Pipe. “By delivering contamination control and quality assurance in a single solution, they allow manufacturers to inspect every product with confidence, protect their brand and profits, and comply with even the most demanding industry requirements.”

Read also

Hygienic Design

If detecting contaminants in the food production process is critical, then preventing them from entering in the first place is just as essential. Poorly designed equipment can be difficult to clean, creating dead spaces where residues accumulate and microorganisms thrive. Cleaning agents and disinfectants can also collect in these areas, potentially damaging equipment and migrating into product batches.

Benedikt Krassort is the European Director of Sales at Unibloc Hygienic Technologies. This US-headquartered company is known for its highly hygienic, easy-to-clean pumps that minimize the risk of contamination and downtime. According to him,

“The biggest challenges we see today are allergen cross-contamination, biofilm build-up, and the lack of skilled labor for cleaning and maintenance.”

Unibloc’s goal is to combine maximum hygiene with real efficiency for food producers.

“Our hygienic lobe pumps, for example, are built with polished stainless steel and minimal dead zones, which helps prevent bacterial growth,” explains Benedikt Krassort. “Our QuickStrip system is a patented, tool-free design that allows cleaning in minutes instead of hours — which is especially valuable today, with so many plants facing labour shortages. And our Air-Operated Double-Diaphragm (AODD) pumps are robust and versatile, making them ideal for transferring viscous or sensitive products without compromizing hygiene.”

Package Sterilization

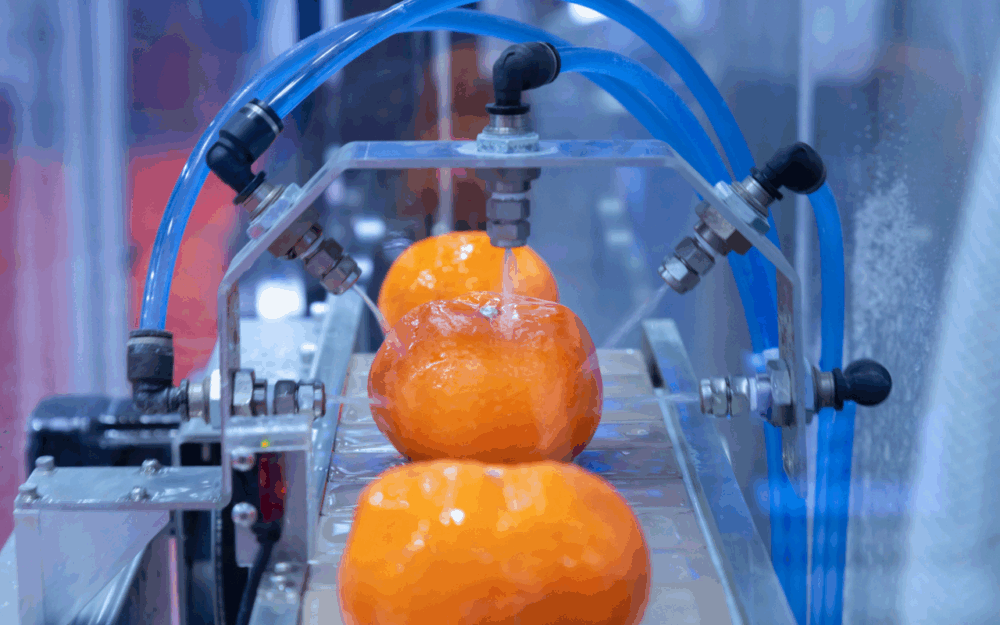

Food packaging protects products from contaminants, preserves freshness, and reduces the risk of illness. To ensure safety, packaging is often sterilized to remove microorganisms and spores, preventing contamination and extending shelf life. Common sterilization methods involve chemical sterilants such as hydrogen peroxide, ultraviolet (UV) light, and superheated steam.

Electron beam (eBeam) technology is a non-thermal, non-chemical innovation in food processing that uses high-energy electron beams to kill harmful bacteria and other microorganisms. The E3/Speed Hyper from Swedish multinational food packaging and processing company Tetra Pak, which employs eBeam technology, is the world’s fastest carton filling machine, capable of producing up to 40,000 sterilized packages every hour.

“eBeam is arguably the biggest innovation in food packaging technology since the Tetra Brik Aseptic carton,” says Par Bertilsson, Tetra Pak’s Director Aseptic & Filling Solutions. “It offers several significant advantages over alternatives like hydrogen peroxide, including faster throughput, which enables high speed production and reduced operational costs.”

Future Focus

Emerging technologies are continually transforming how companies detect, prevent, and manage food safety hazards, with advanced solutions such as AI-powered monitoring, blockchain-enabled traceability, and real-time sensor systems raising safety standards across the food industry. These innovations are delivering greater transparency, predictive insights, and automation — empowering professionals to identify and mitigate risks before they impact products or consumers.

“Over the next decade, product inspection systems supporting food safety and upholding hygiene values will become increasingly intelligent and connected,” says Mike Pipe. “Smart inspection systems capable of sharing data across networks will support predictive analytics and faster decision-making. Artificial intelligence is expected to enhance contaminant detection by recognizing anomalies and patterns beyond the capabilities of traditional technologies, improving accuracy while reducing false rejects.”

Moving forwards, Inspection technologies such as checkweighing, metal detection, X-ray and vision inspection will continue to converge, creating fully integrated platforms that deliver multiple layers of protection in a single, hygienically designed system. We will also see advances in automated or semi-automated cleaning, reducing downtime and reliance on manual processes.

At the same time, regulators are pushing for greater transparency, meaning digital traceability and compliance ecosystems will become standard, with every stage of production monitored and validated. As systems become smarter and more connected, food producers will be able to inspect more thoroughly, protect more effectively, and comply more easily than ever before.

Read also

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)