Food traceability has become important. Consumers increasingly seek accurate and accessible information about the origins and journey of their food. Fortunately, technology is stepping in to revolutionize the way food producers manage and communicate this critical data and therefore help fight counterfeiters.

Article updated on December 13th, 2023

According to a recent study published in the Journal of Agriculture and Food Research, food fraud and counterfeiting cost the global food industry about €30 billion annually. The problem is particularly dire for producers of organic food, seafood, supplements, and olive oil. Additionally, it affects the brands that are tied to a region of the world or that rely on a traditional manufacturing process that can’t be replicated elsewhere.

While fraudsters have become increasingly creative to elude controls and detection, helped by the complexities of the global food chain, recent technological advancements have enabled innovative solutions to help the industry improve traceability and fight counterfeiters.

A Microchip Inside Italian Parmigiano

In Italy, the Consorzio del Formaggio Parmigiano Reggiano, the entity overseeing the production of the famous Italian cheese, has recently started embedding edible microchips in cheese wheels. This is the next step in the fight against counterfeit products that dates back decades.

In 1996, Parmigiano Reggiano obtained the coveted Protected Designation of Origin (PDO) from the EU. This label allows only real Parmigiano to be marketed as “parmesan” in Europe. The PDO moniker is not equally recognized globally, though. Certainly, it hasn’t stopped other producers and counterfeiters outside the Union from trying to sell all sorts of cheese as parmesan on global markets. The addition of microchips to cheese wheels aims at thwarting a business that, according to figures from the Consorzio, is valued at about €2 billion globally each year. For comparison, sales of real Parmigiano reached €2.9 billion in 2022.

The chip, as small as a grain of salt is activated by light. It is placed onto the external skin of the cheese wheel, near two QR codes also used for tracking. According to the chip manufacturer, the US-based p-Chip corporation, the tiny component acts as a “digital anchor” for the physical item. It enables granular and effective unit-level tracking. It works by associating a “unique and unchangeable identifier” to each wheel. This therefore creates a digital twin that can be followed through the whole supply chain.

QR Codes

The push to fight counterfeiting with technology isn’t due only to economic reasons. It also stems from regulators acting to ensure that digital traceability gets taken seriously by all food producers. In the EU, the upcoming Sustainable Product Regulation and the “EU Digital Product Passport” will require detailed data to always be available for products at all supply chain stages. It will mandate that everyone in the product’s value chain be able to access pertinent tracking information about the product at all times.

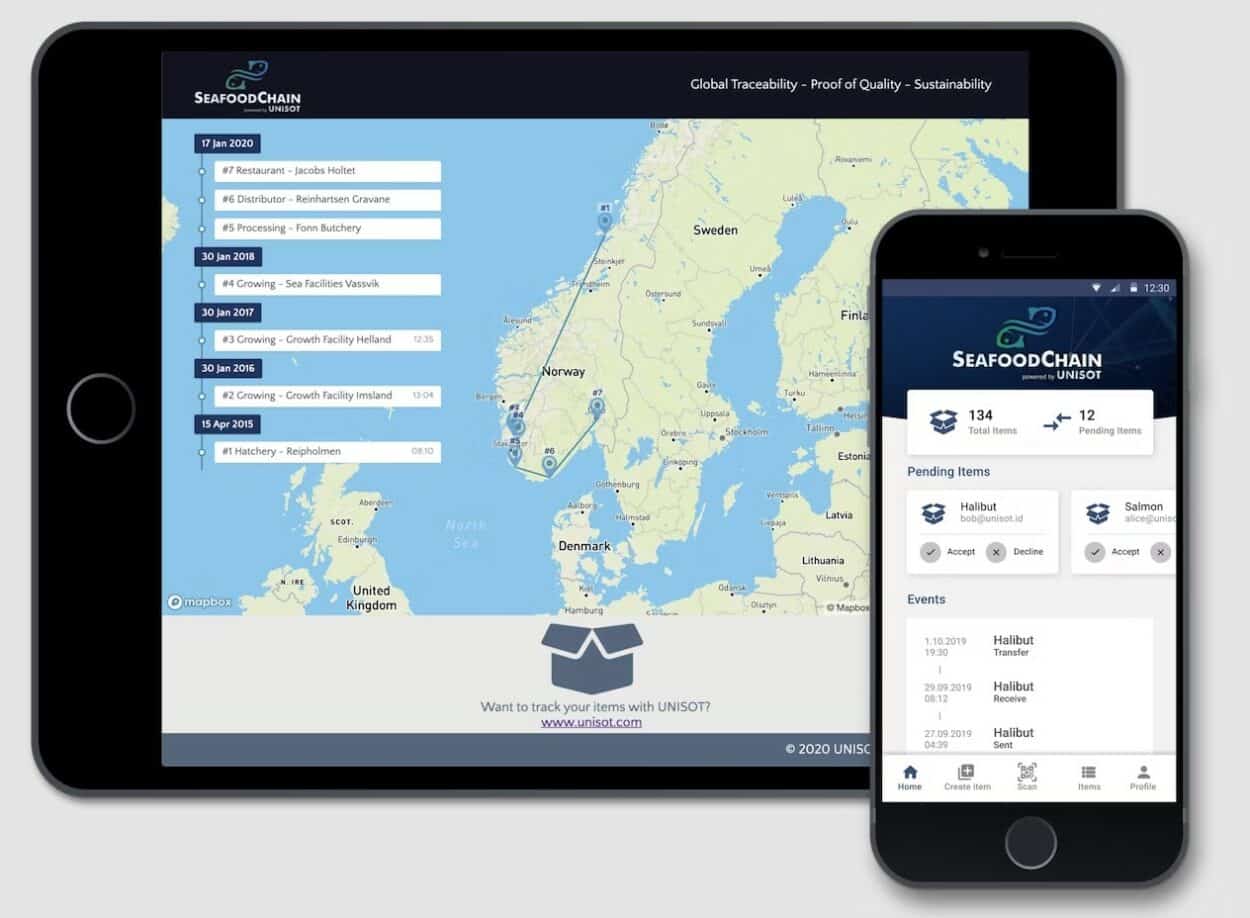

The new regulatory environment has contributed to the growth of several companies offering all-in-one traceability solutions that include IoT systems and cloud-based platforms. A one-stop solution to all digital traceability needs is provided by Norway-based Unisot, a company that operates a cloud-first platform. The system collects relevant information, including product origin, storage conditions, and quality, and makes it easily accessible through a simple QR code. This QR code allows users to trace back all the data at any time.

To minimize the risk of data manipulation, solutions like the one from Unisot store all the information in a publicly queryable blockchain. Blockchain has already become one of the most useful practical applications of the digital ledgers commonly associated with cryptocurrencies.

Blockchain

Germany’s Siemens offers a similar blockchain solution with its “MindSphere” cloud-based IoT operating system. Siemens’ solution can handle any data source, including consumer feedback, weather forecasts, ERP reports, and more. According to the company:

“With the prevalence of internet access, cloud computing, and the decreasing cost of the Internet of Things (IoT), it is now possible to generate, manage, and communicate data effectively. In combination, blockchain and the Internet of Things can generate immediate benefits and revolutionize Food and Beverage supply chains and traceability”.

Siemens’ solution also has a client-facing endpoint. By scanning a QR code, consumers can quickly access all relevant information about the product, and follow its entire supply-chain journey. This ensures that the product they put on the table is genuine and that all ingredients match what’s written on the label.

In the US, the Food and Drug Administration is following a similar path. By 2026, the Food Safety Modernization Act will require many food manufacturers to keep records and make them easily accessible. While fraud detection and prevention is still one of the goals, the FDA also aims to better follow and control foodborne illnesses.

Food-Safe Tags

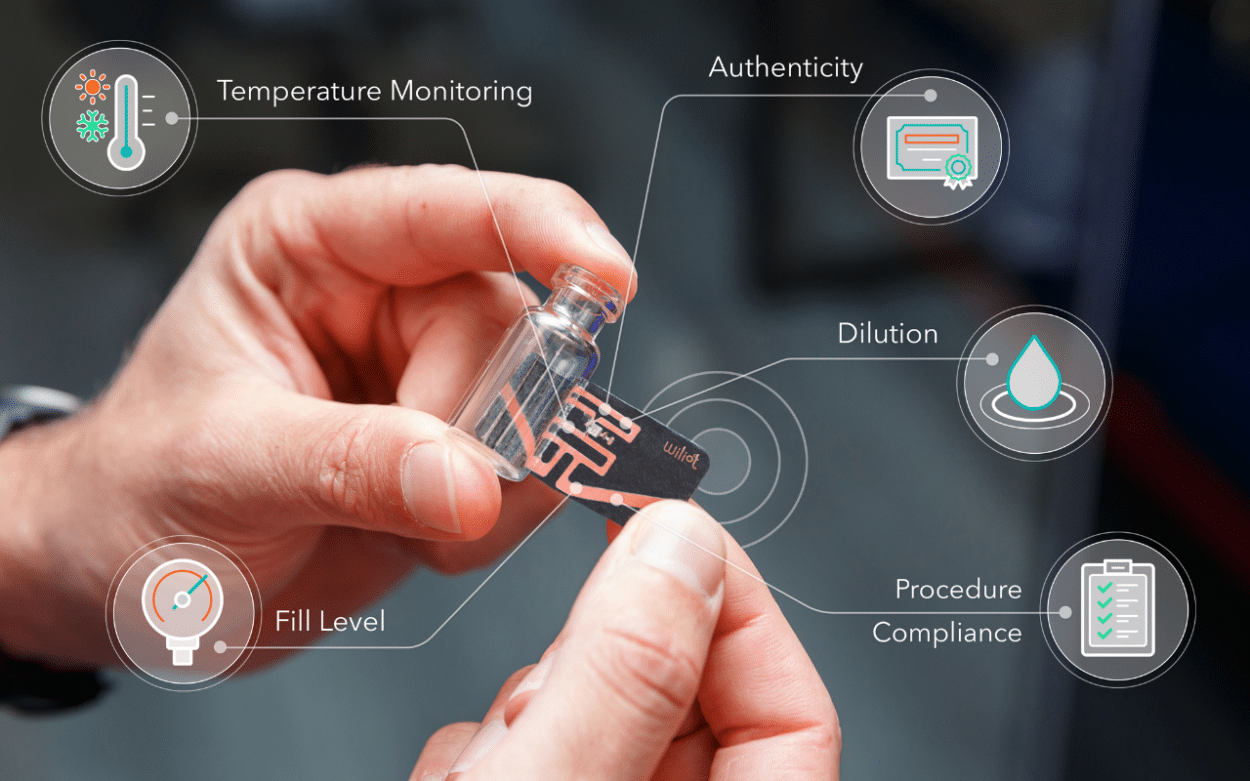

The American supply-chain management company Wiliot started offering solutions to help companies reach compliance with the FDA requests before the deadline. One of the company’s most recent products is Pixel. Producers can attach this food-safe flexible tag to any type of food, packaging, or container.

Pixels are battery-free chips the size of a postage stamp that power themselves by harvesting radio waves. Each intelligent label has no technical end-of-life. It operates with minimal infrastructure costs. And it can both work as a sensor for gathering supply chain parameters or a label to access supply chain data.

According to Wiliot, its IoT Pixels can fully digitalize the entire product journey. It can help manufacturers achieve optimum traceability, understand the movement and condition of their products, and ensure present and future regulatory compliance.

The application of IoT solutions doesn’t help just with fraud prevention and compliance. A more transparent supply chain and blockchain-based solution for traceability can also help with sustainability. This could assist companies in validating their environmental claims with verifiable data and reducing food waste.

The latter, in particular, is the focus of a large project by IBM, the IBM Food Trust. By leveraging IoT and Blockchain solutions, the Trust creates a secure and shared record of all transactions along the supply chain. Food producers have better visibility at every step. They can achieve new levels of trust and transparency, making food safer in a smarter way.

Artificial Intelligence

In December, researchers at the University of Geneva were able to identify the “exact origin” of several renowned Bordeaux wines solely based on their chemical components. This was made possible thanks to artificial intelligence. Their method was published on December 5th in the journal Communications Chemistry. It holds promise in “combating counterfeiting.”

The researchers analyzed 80 red wines from seven estates in the Bordeaux vineyards. They were able to separate the molecules that result from the complexity of blends thanks to gas chromatography. They then used a mass spectrometer to translate these chemical separations and molecule density into a graph. Resembling an extensive electrocardiogram, the graph comprises up to 30,000 points.

Alexandre Pouget, the head of the neuroscience department at the University of Geneva, and his team developed a machine-learning solution to process the raw data. According to them, their AI-driven system successfully identified a consistent pattern among vintages from the same estate, within thousands of data points. This discovery proves that each terroir has its distinctive “unique chemical signature.”

For the researchers, this terroir identification technique based on AI could effectively help detect counterfeits. It costs around a hundred euros.