From HANNOVER – Magnetic levitation has already revolutionized transportation with the Maglev trains in China, Germany and Japan. Festo’s new concepts could bring about a revolution on the factory floor using the same superconductor technology.

At Hannover Messe, Festo will officially present new potential industrial uses for magnetic levitation that could have tremendous applications in the transportation of workpieces and materials within a factory.

For several years, the German company has invested in this contact-free technology, made possible by cooling the magnetic field of a permanent magnet below a certain temperature to hold it in suspension at a predefined distance.

Three new pilot projects will be showcased. They will enable transferring objects without any contact and even holding and moving them on suspended rollers.

- SupraCycle will allow the transfer of objects without any contact from one automation module to another or beyond system limits.

- With SupraHelix, 360° rotation of ring-shaped workpieces will be easy to execute without any expensive control technology.

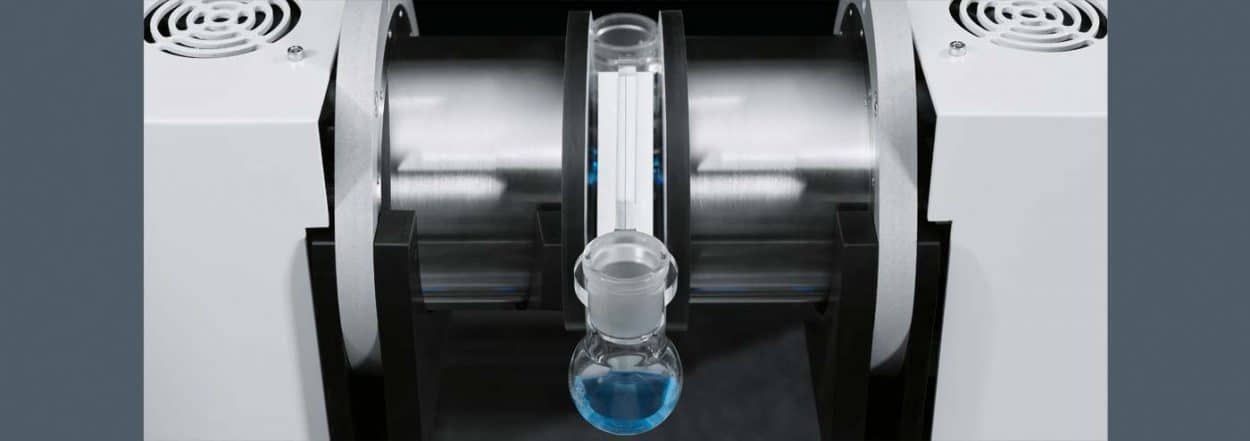

- SupraCarrier will store and move materials such as flat and non-ferromagnetic products on suspended rollers

The advantages of such contact-free modules are numerous. Automation with superconductors can be applied to areas that are difficult or impossible to automate, for example, manipulating products from behind walls. The frictionless manipulation of objects also means no dust and no abrasion which contributes to maintaining clean environments inside the factory and better protecting the moving workpieces. The different applications operate silently. The icing on the cake—motion in suspension requires minimal energy consumption.