Where and how are the Luxembourg chairs, Bistro chairs, and Oulala nesting tables from France’s most colorful furniture maker produced? We had the chance to visit Fermob’s factory in Thoissey, near Lyon. It’s here, in France, that the brand’s iconic, brightly colored, and instantly recognizable furniture is made. We followed the entire manufacturing process—from the raw material, steel, to the boxing of the finished, painted products. Along the way, we discovered a concentration of industrial know-how and unique technical expertise.

Watch our video inside the factory

A Brand You Already Know

You know the brand. You’ve probably already sat on a green Luxembourg chair in Paris’s Jardin du Luxembourg or on a red folding Bistro chair in New York’s Times Square. If you’ve worked at Google or studied at Harvard, you’ve likely seen and tried them there too. You know Fermob. But did you know that this outdoor furniture maker, famous for its bold colors, is French? And that the pieces you’ve tried are 100% made in France?

DirectIndustry had the privilege of spending time with the family behind this French success story. At the helm: Bernard Reybier, CEO, and his son, Baptiste Reybier, Managing Director. The father-son duo opened the doors of their Thoissey factory to us, located about an hour north of Lyon. It is here that Fermob’s industrial heart beats. The company manufactures thousands of metal pieces every day.

Color, the Driving Force Behind Fermob

Fermob’s garden furniture, recognizable by its metal lines and 25-color palette, is a showcase of industrial know-how. It is also a family adventure that began in Thoissey at the end of the 19th century as a small ironworking shop, before being taken over in 1989 by Bernard Reybier, an EM Lyon graduate, who bought the ten-person workshop specializing in wrought-iron garden furniture.

“Steel is a fabulous material,” begins Bernard Reybier. “The drawing you have in your head—we can make it with a 10-millimeter metal rod.”

With his son Baptiste now at his side, Bernard transformed Fermob into a reference brand in the world of 100% made-in-France garden furniture. Among its iconic, globally recognized pieces: the folding Bistro chair, which has existed since 1889 and is still sold today, and the Luxembourg chair, first crafted in the 1930s by Fermob’s predecessor and now making up 70% of the seating in Paris’s Jardin du Luxembourg.

The innovation behind this success story is, above all, color. The company set itself apart from competitors by offering its products in shades that were highly unusual for outdoor furniture in the 1980s and 90s: fuchsia, orange, bright yellow. This palette became the brand’s hallmark—and its secret to success. And for Bernard, it was self-evident:

“Metal takes color very well. And color has an important social dimension. Twenty-Four colors a day keep the doctor away! But color in the garden isn’t an artistic revolution—it’s a technical one. On one hand, I have a passion for industry; on the other, for creativity and design.”

Today, Fermob employs 500 people and generates €150 million in revenue, half of it from abroad. The company relies on three French production sites: the historic Thoissey factory (14,000 m²), where most products are manufactured; Anneyron in the Drôme region (20,000 m²), specialized in aluminum and painting; and Mâcon (7,000 m²), where its subsidiary Vlaemynck makes cushions, including those for the Belleville range.

It was to Thoissey (Ain), the historic site, that we traveled for our visit. Our guide through the factory is Simon Piguet, site manager.

A Steel-Driven Organization

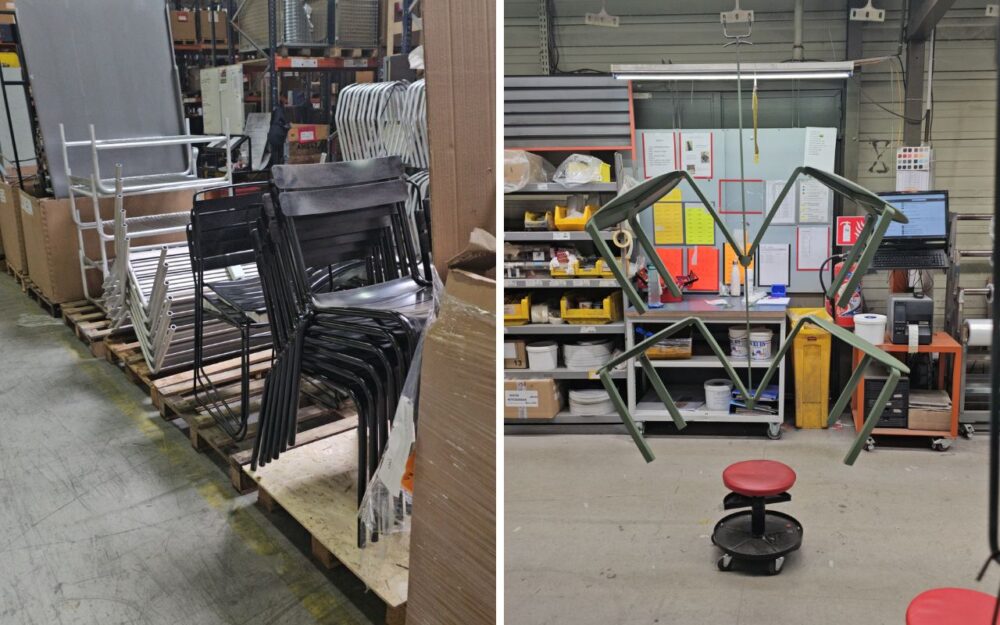

At the heart of Fermob’s production chain is the Thoissey factory. Here, 20 tons of raw material are processed every day, and up to 15,000 products are manufactured weekly.

The starting point for every Fermob product is steel, which arrives at the factory either in sheet form or as coils.

“We order our raw material from local steelmakers. The steel itself comes from national or sometimes European manufacturers. We place orders in precise formats, with lengths and widths tailored to our needs and our products. That way, we generate virtually no scrap,” explains Simon Piguet, manager of the Thoissey site.”

At this site, 90% of the raw material used is steel and 10% is aluminum. The aluminum bars, used for the Luxembourg range, come either from Asian producers or from Fermob’s Anneyron site. At Thoissey, the main material worked is galvanized steel coil: strip coil and wire coil. These 2.5 km-long coils are zinc-treated to resist corrosion.

In-House Tooling: A Strategic Asset

A key feature of the company is that every Fermob product requires its own tooling, designed and manufactured in-house. Dies, templates, bending tools, even the hooks used for hanging painted products—each is tailored to a specific product reference. This expertise is the company’s true intangible capital.

“This is real strategic know-how and a true treasure for Fermob. Each time we develop a product, we start from a designer’s sketch, move through prototyping, and then into production and industrialization. In that industrialization phase, Fermob teams design, develop, and manufacture the necessary tooling,” says Piguet. “Every new product therefore means a new tool.”

Among these tools are machines for stamping, forming backrests, or producing chair slats.

“If the factory were to burn down, the loss of finished or semi-finished products would be nothing compared to the loss of these tools, because production couldn’t simply restart. We would need to rebuild every single tool. That’s why we are extremely careful about maintaining and protecting them.”

According to Simon, this investment shortens development timelines: between 12 and 24 months from prototyping to market launch.

The factory runs in batches of 50 to 200 pieces, optimized to minimize tool changeover times. The parts are then stored as subassemblies (tabletops, bases) before final assembly.

The Bistro Chair, Star of the Brand

And so we arrive at the brand’s superstar: the folding Bistro chair. Starting from a strip coil, Fermob manufactures and assembles its best-selling product.

“We run the coil through a first machine, a straightener-flattener, to obtain a perfectly flat material. Then it passes through a press where it is cut and punched. This thick, narrow strip becomes the slats of the Bistro chair,” explains Piguet.

Here, one Bistro slat is made every second—that’s nearly 2 million per year. Another machine, using the same strip coil and process, produces the rods that become the chair legs.

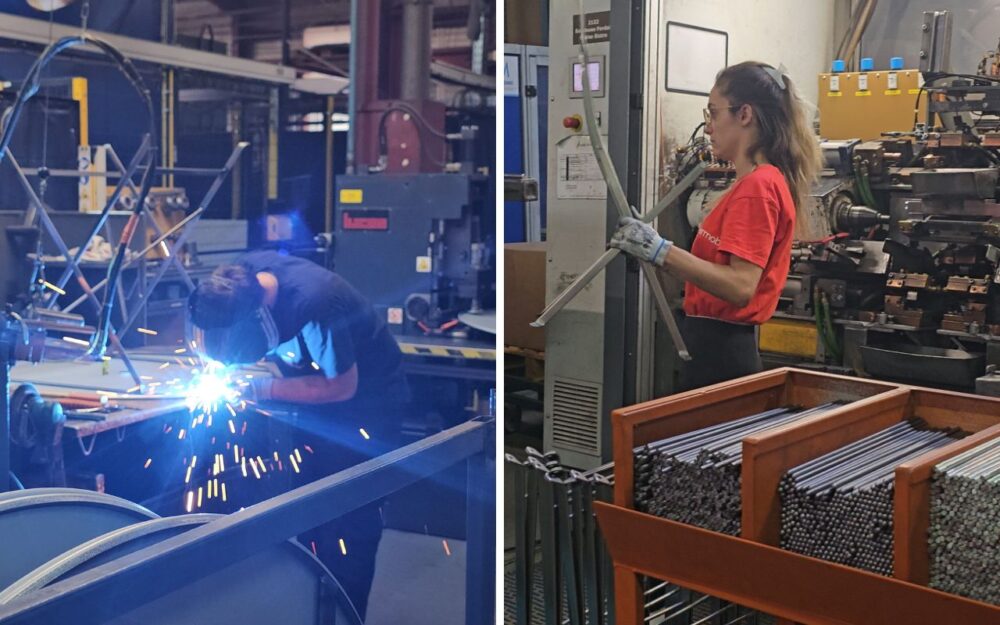

Three successive workstations then transform these first parts into a folding chair. At the first station, operators bend the legs, twist, and curve the metal to position the chair backrest.

At the second station, assembly of the legs begins—with a unique detail to ensure the chair can fold:

“We weld all the crossbars except the middle one, where we use a heading process instead. In the center of the machine, two rotating drill spindles compress the material until it softens slightly, then flatten it into a mushroom-shaped head. So the two legs aren’t welded together, but they still won’t come apart—and this creates the pivot point for opening and folding the chair.”

Finally, in the last step, the backrest is assembled with the slats:

“We position the slats on the frame and rivet them all at once—like stamping a license plate.”

On these three production lines, with three operators, 450 to 500 chairs are made per shift of 7.5 hours. That adds up to 220,000 Bistro chairs per year. At full capacity, running three shifts, the factory produces 5,000 chairs per week.

The Oulala Table

Beyond strip steel for slats, the factory also works with wire coil to create three-dimensional elements. This is the case for the legs of the Oulala nesting table, produced in three sizes. A dedicated machine shapes the wire progressively in all dimensions until it forms a finished leg ready for welding. The task is then handed over to welding robots using the MIG/MAG process.

The Thoissey factory masters five welding techniques: aluminum MIG-MAG or TIG, steel MIG-MAG or TIG, and brazing. When production volumes do not justify automation, welding is carried out manually in one of the plant’s seven welding booths—a flexibility that is essential to handle the wide variety of products.

Painting Designed as a Flow

Once the raw models are assembled and welded, it’s time to paint them. Color—the Fermob hallmark—requires a highly specific organization. The 25 shades are rotated every 72 hours, with an optimized sequence moving from dark to light to minimize changeover times. A technical feat that is anything but accidental.

As CEO Bernard Reybier explains:

“In 1996, I invested a quarter of Fermob’s revenue in an installation that allowed me to offer all colors at the same price and in the same lead time. Here, we hold the world record for color change—it’s no joke. In six minutes, we can go from green to red, from red to yellow, and so on.”

The brand’s signature “cactus” green accounts for 40% of volumes. And indeed, during our visit, that was the shade being applied to a batch of products as varied as tables and chairs.

“We think in terms of color time, not number of products. Each run has to last at least an hour to be cost-effective,” notes site manager Simon Piguet.

At the plant, 95% of the time, fewer than 5% of identical products are painted one after another. It’s common to see Luxembourg tables, legs, and frames all moving through the line at once, a striking diversity.

Pieces are painted in a booth with two sets of robotic arms applying powder coating automatically. For certain parts—like slats that are particularly tricky for robots—a human painter handles them manually at the entry point. Overspray is collected and reinjected, ensuring no waste.

The painted parts then spend 20 minutes in an oven at 190°C to set and cure the powder. Once painted, they are hung to cool and inspected 100%—visually and by touch—by two workers. From the moment a part is ready for painting to the time it’s boxed, the full cycle takes just two hours.

Once packed, the cartons leave the factory for a logistics hub. At Thoissey, the pace reaches 15,000 products per week. Three shuttles connect continuously with the logistics provider, which ships out around 15 trucks per day.

Flexible Processes, Not Full Automation

While the factory does rely on welding robots and painting robots, automation remains limited. The product range is so broad that once operators have produced 200 identical pieces, demand is essentially covered for the next two to four weeks.

“Setting up fully automated lines with conveyors and dedicated systems just isn’t possible,” explains site manager Simon Piguet. “The ranges are too diverse, and production runs are too short.”

Instead, the shop floor is organized around hybrid workstations that combine machines, manual welding booths, and robots, depending on the volume required. This balance allows Fermob to stay agile and to adapt production precisely to market demand.

Indeedd, as a specialist in garden furniture, the factory and industrial organization are shaped by seasonality. The site employs between 120 and 200 people depending on the season. For example, a third of capacity is enough in September, while between February and June the factory runs at full speed, sometimes around the clock in three shifts. To handle these peaks, Fermob builds up inventory in winter for spring sales—the company’s busiest period.

Industrial Expertise in the Service of Design

From a designer’s sketch to the store shelf, Fermob’s production chain is built on a subtle mix of tradition (manual welding, riveting), innovation (in-house tooling, robotic painting), and flexibility (short series, seasonal storage).

This strategy ensures the company can deliver finished, ready-to-use products without delays—whether in its 25 colors or for demanding international markets.

Inside the Thoissey workshops, rows of Bistro chairs line up by the hundreds, waiting to be shipped to cafés, terraces, and balconies in Paris and beyond.

Read our other “Inside the Factory” Stories

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)