The world of microtechnology includes all miniaturized devices using various technologies: micromechanics, microelectronics, optics, and electrotechnics. Microtechnology enables applications in all cutting-edge sectors that require the smallest, most precise, and most intelligent solutions, from aerospace to medical to automotive. Today, where there is a need for efficiency, optimization, and productivity, how can microtechnology be made smarter? Several solutions already exist, and not all of them require you to renew your entire set of machines.

We attended the press conference for the presentation of the Micronora trade show which will take place in September 2024 in Besançon, France, dedicated to the microtechnology industry. This year, one of the main themes of the trade show will focus on intelligent microtechnology. Several technologies, including smart sensors, machine tools, and metrology equipment with intelligence, will be exhibited.

A Need For More Intelligence

With Industry 4.0 and the scarcity of resources and energy-related issues, it becomes vital for industrial companies to integrate intelligent solutions into their production processes. These solutions can, for example, optimize production through real-time data collection and analysis. They can also enable equipment failure detection, improve machine performance, better allocate resources, and reduce product defects through enhanced quality controls.

According to Sébastien Thibaud, Professor at Sup MicroTech ENSMM (National School of Mechanics and Microtechniques),

“To improve productivity, it is crucial to anticipate failures and difficulties in the production process, especially for increasingly smaller and more precise parts, which is a characteristic of microtechniques. Intelligent controls are necessary to ensure quality at the end of production. It is also essential to have increasingly efficient, productive, and versatile machine tools.”

The integration of intelligence into all production and control equipment for microtechnology is thus becoming a major challenge. Let’s take a look at the solutions already available on the market.

1/ Smart Sensors

It all starts with sensors. Industrial intelligence relies increasingly on data collection from smarter sensors, Sebastien explains:

“The issue is which data to collect, what data is relevant, how to transfer it, and how to process it. To collect this data, we use smart sensors. There are more and more sensors in machines; this is characteristic of Industry 4.0 and soon Industry 5.0.”

These sensors provide real-time or interval-based information on equipment or parts. They monitor the condition and lifespan of parts or components subjected to natural events such as deformation or wear.

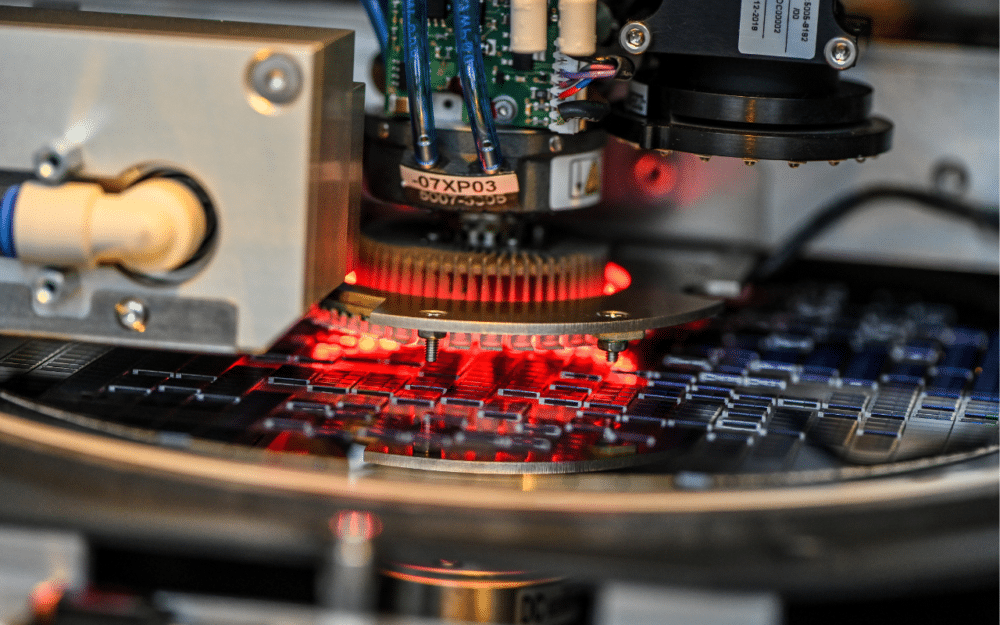

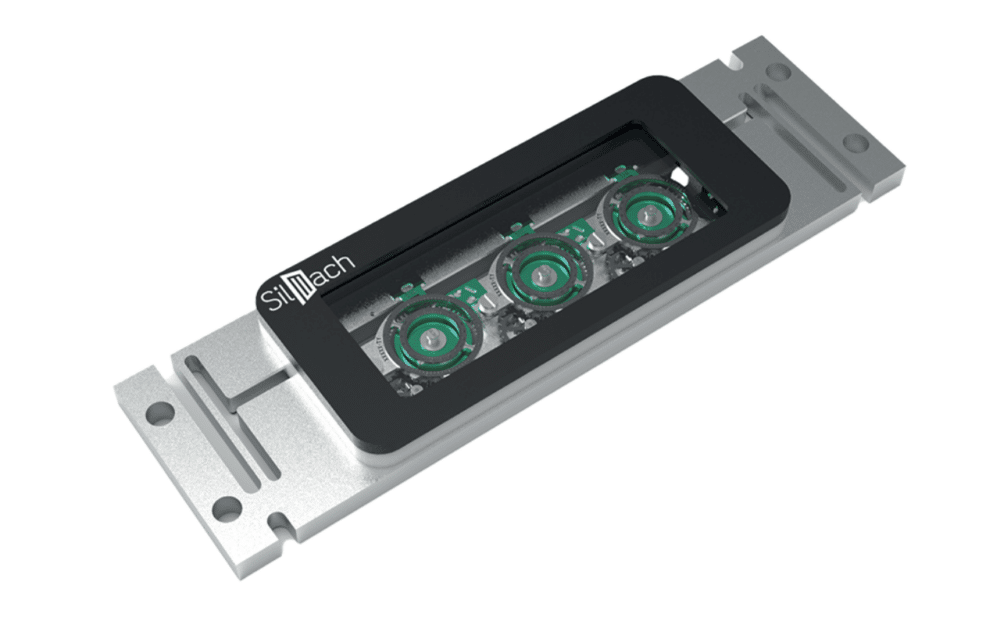

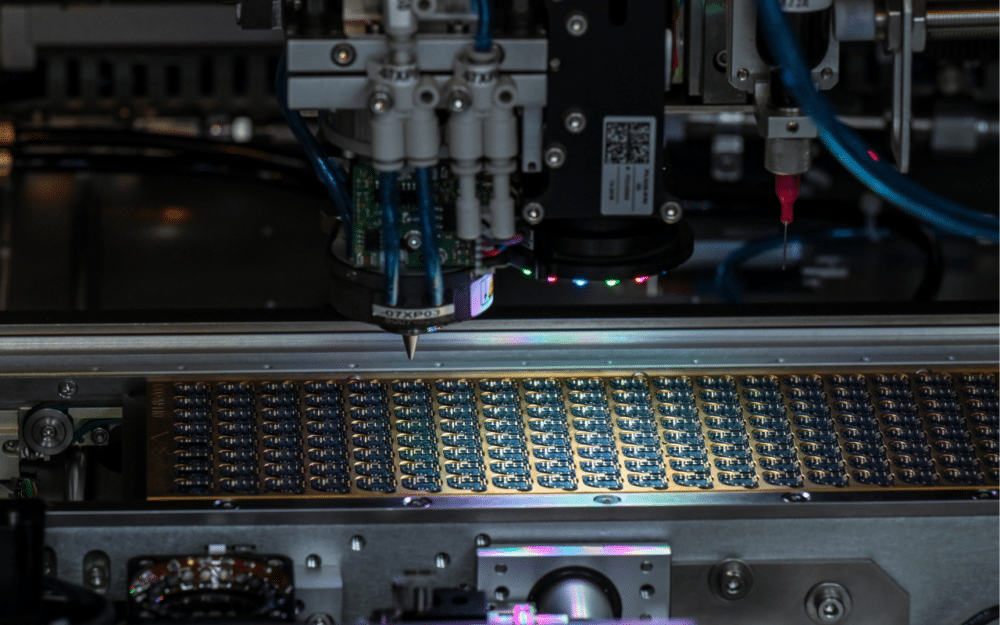

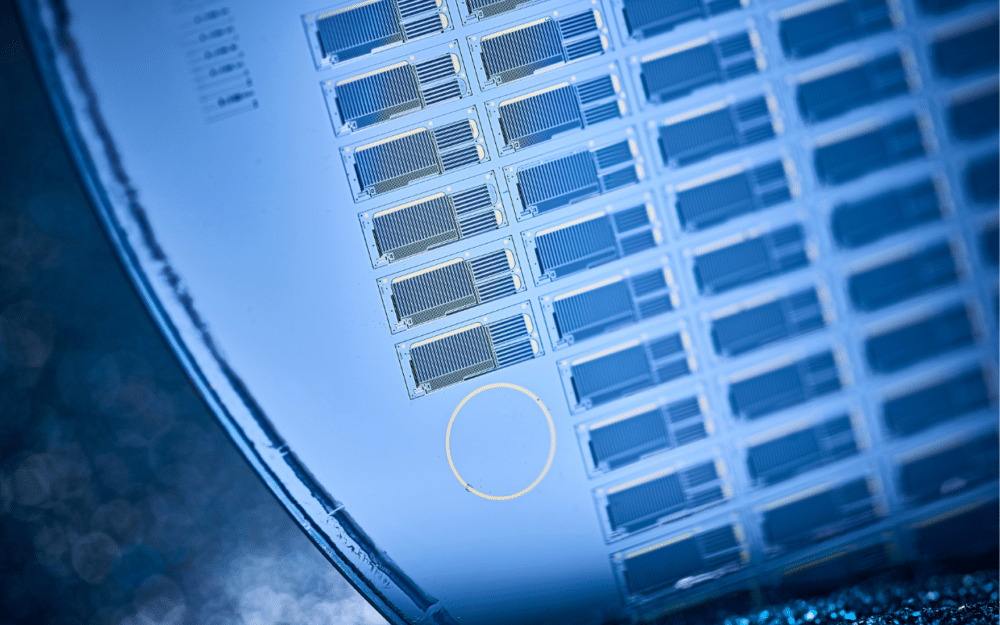

SilMach, for example, has developed a Structural Health Monitoring (SHM) technology that enables tracking real damage, detecting critical events, and optimizing maintenance based on the condition of the equipment.

They have developed two major innovations:

ChronoMEMS® is a range of passive and autonomous micro-sensors, devoid of electronics or batteries, that monitor the condition of structures and optimize maintenance. These sensors detect various events (mechanical stresses, thermal expansion, pressure variations, vibrations, and shocks). They can be used independently or combined with other devices. A passive UHF RFID version allows remote interrogation.

PowerMEMS® concerns micromotors for watchmaking. SilMach micromotors stand out for their autonomy, immunity to magnetic fields, precision, and smooth movement of the hands. They are also compatible with Surface Mount Technology (SMT) techniques. These disruptive characteristics open up a wide range of applications in various sectors such as defense, medical, aerospace, and transportation. In the medical field, SilMach micromotors allow for the miniaturization of implants while offering high autonomy. They can also serve as a new generation of motors for small-sized valves.

“So these sensors are one of the examples that can be incorporated into devices, for example, to capture shocks or deformations.”

2/ A Smart Microtechnology Production Line

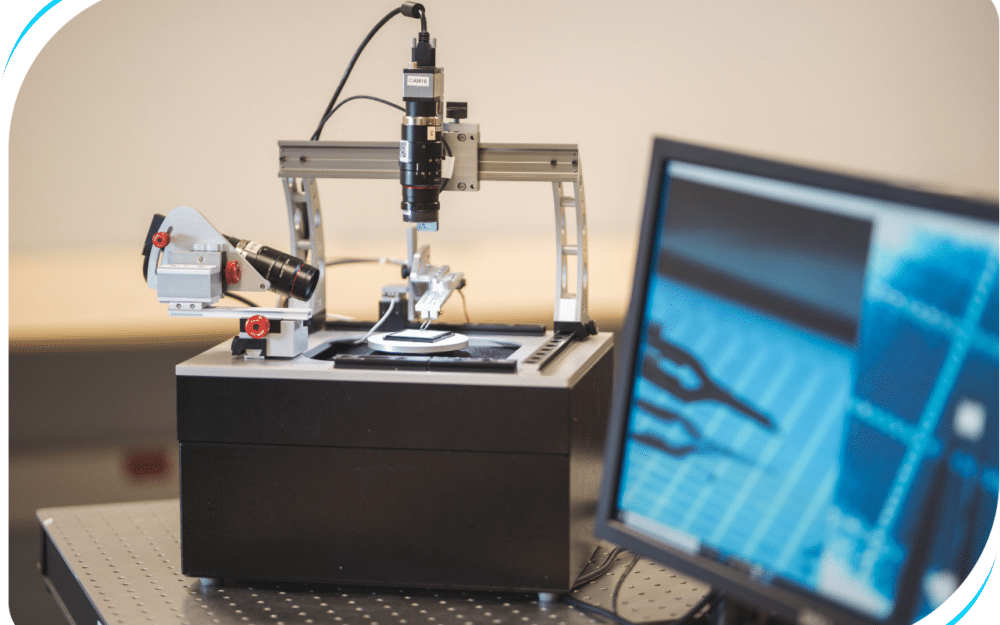

Improved metrological control of the shape and roughness parameters of parts is a guarantee of productivity. Modern measurement systems are essential components of quality control. Today, to ensure robust, consistent, and reproducible results, they must be fully automatable. Additionally, technology with industrial standard interfaces is necessary to enable networking and communication between all production systems.

In this perspective, during the Micronora trade show, a smart microtechnology production line will be showcased. It will bring together a machine that produces parts output by a cobot and will be inspected by another machine, all with the assistance of artificial intelligence, explains Sébastien.

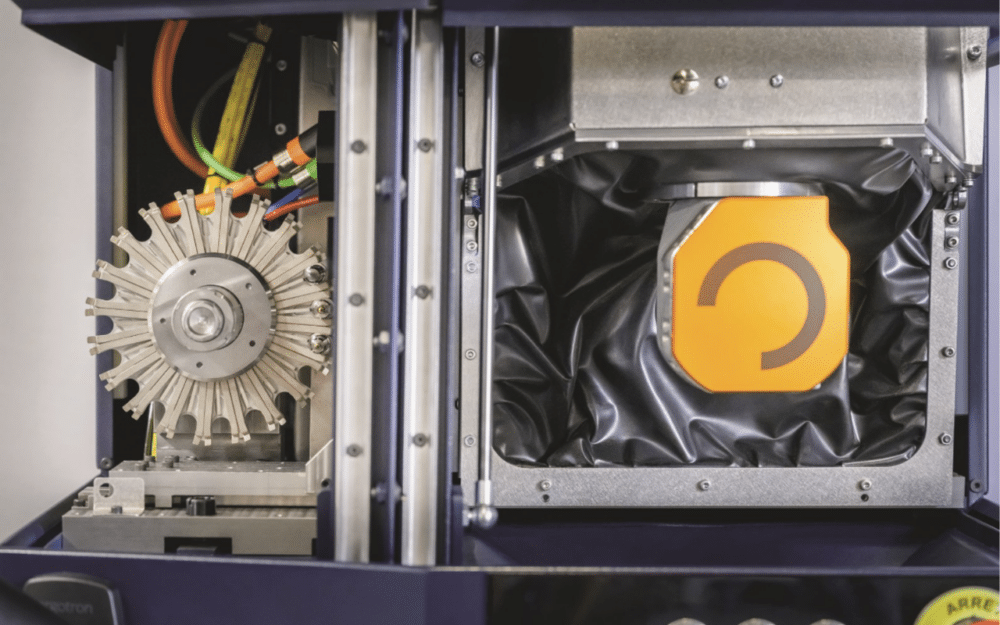

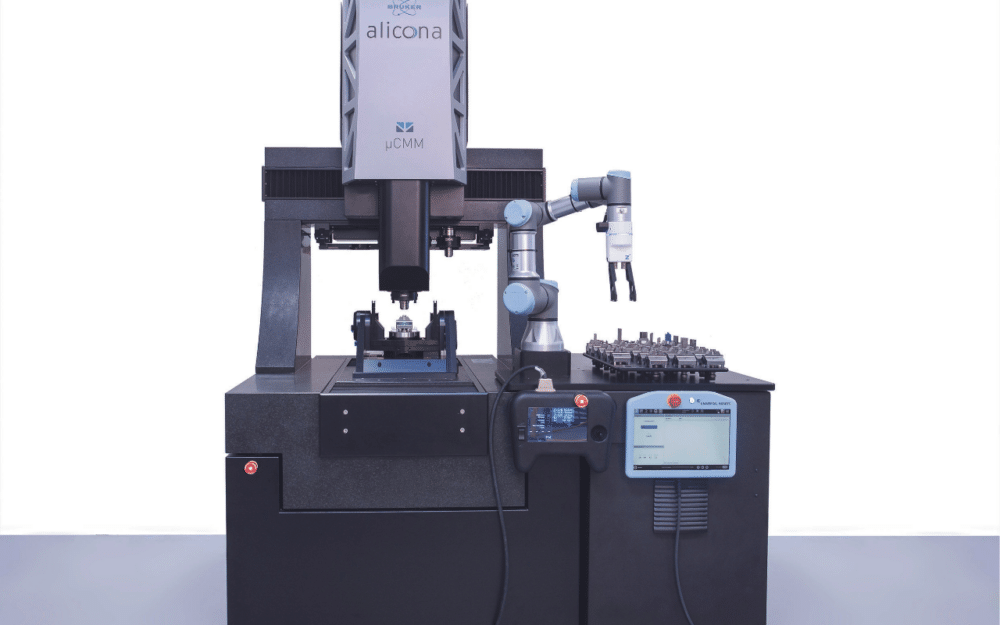

“We will demonstrate what a smart microtechnique production line would represent. There will be a high-precision machining center by KERN which will manufacture ultra-precision components. These parts, once produced, will be removed from the machine by the MORFOSE cobot from MS-INNOV, a cobot manufactured in France. Then, an optical metrology machine, μCMM from Bruker Alicona equipped with a Pick & Place robot, will inspect the parts.”

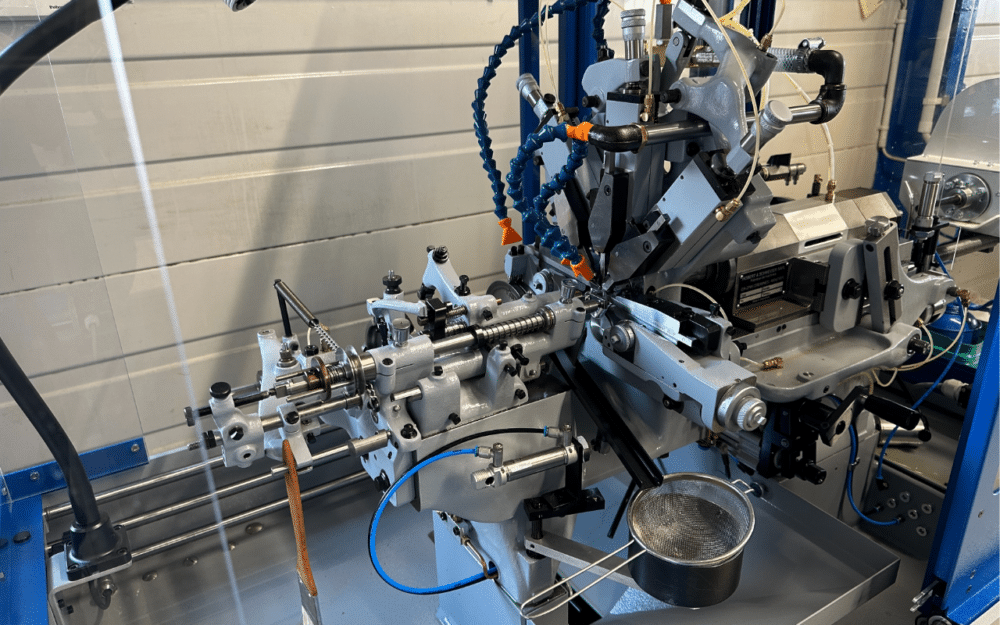

The Kern Micro HD enables precise machining with good surface quality due to hydrostatic guides, better dimensional accuracy, and better repeatability.

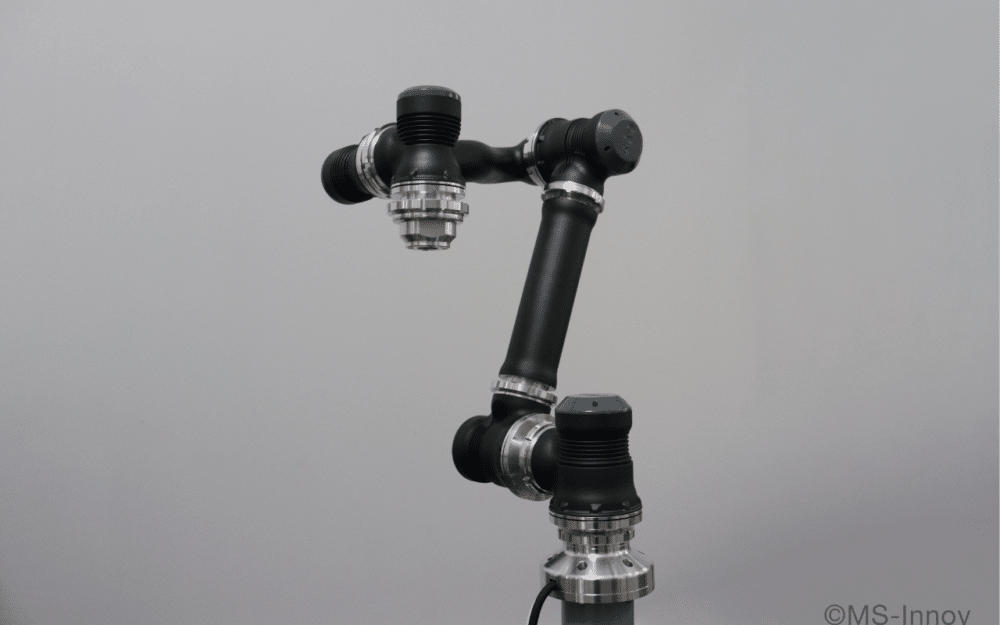

The collaborative robot MORFOSE, by MS-Innov assists the operator in handling, quality control, assembly, deposition, and removal of material. Modular, it is capable of adapting to its environment and the needs of its users. Each module of MORFOSE has the capacity for infinite rotation, which allows for improved cycle times and therefore productivity.

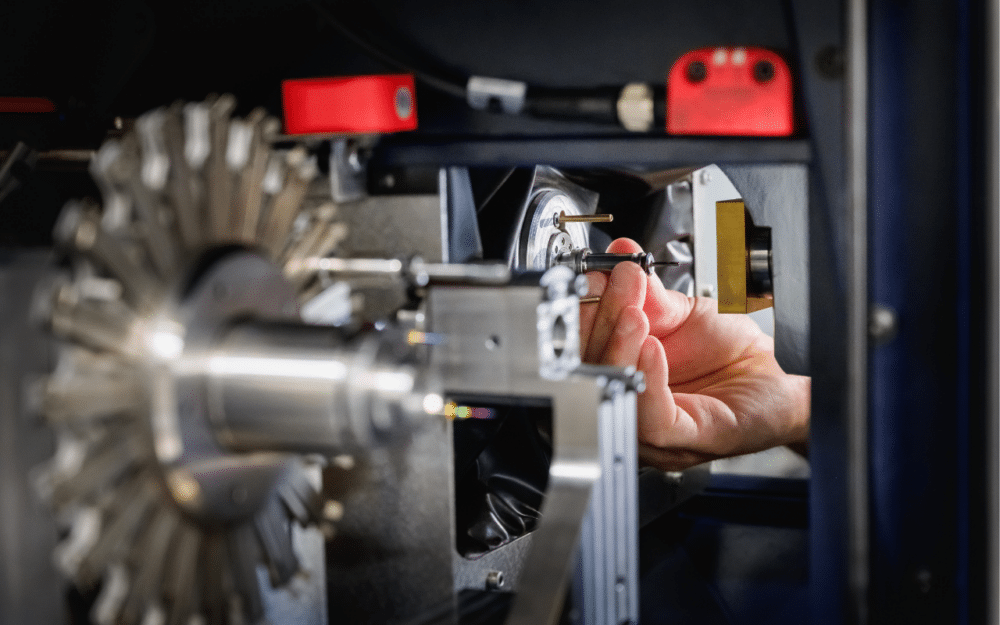

Bruker Alicona offers solutions based on the Focal Variation technology which enables automated measurements of dimensions, position, shape, and roughness, as well as effective data and quality management. Machine-to-machine communication is also possible, integrating metrology directly into the networked manufacturing chain, with sensors detecting non-conforming parts.

“We will see how we can interact automatically and intelligently between a machine tool, a cobot, and a metrology tool and potentially provide feedback to the machine.

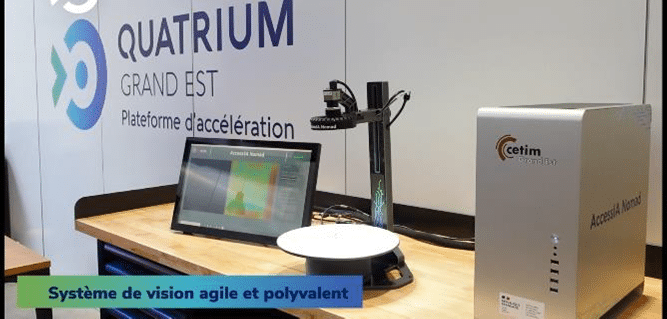

The Technical Center for Mechanical Industries (CETIM) has also developed an intelligent vision control system using deep learning to make sure that the part, from an aesthetic point of view, meets the right specifications and criteria.

“The more parts we pass through this machine, the more it will learn, the more it can control the appearance effects and therefore sort parts as we go along. The more information you give it, the more it will be able to sort and differentiate between a good and a bad part.”

This technology is a good alternative to conventional visual inspection technologies, which are a source of fatigue and therefore errors.

4/ Increasingly Intelligent Machine Tools

We are increasingly seeing in the microtechnology world, machine tools becoming smaller, whereas before they were quite large and massive.

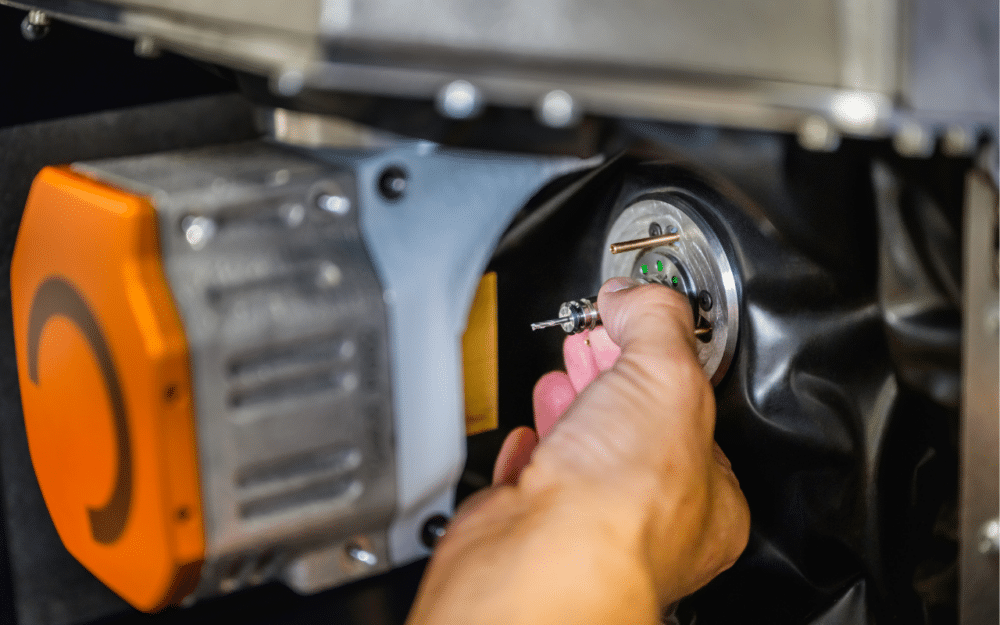

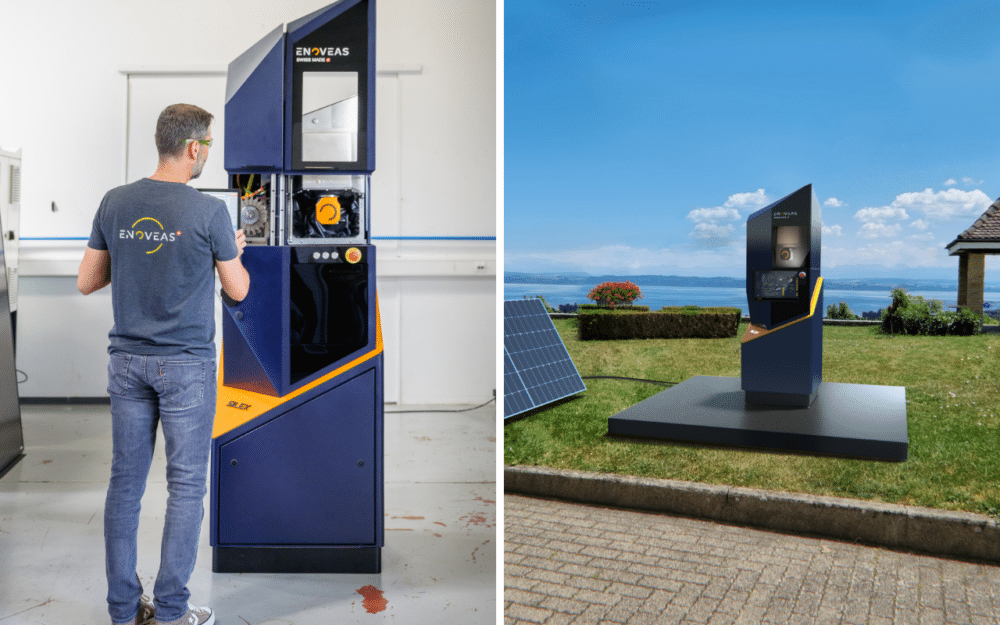

Introduced in August 2023, SILEX by ENOVEAS is a disruptive high-performance micromachine. The size of a refrigerator (with a reduced footprint of 0.43 m2), has the same capabilities as a production machining center. Its production speed is even increased for precision machining (with maximum dimensions of 50 x 50 x 50 mm). But it is also characterized by low energy consumption (< 1 kWh) and a scalable modular system.

According to Sébastien,

“Today we see a very large number of industrialists starting to take an interest in smaller machines that allow for a lot to be done while consuming less energy than a conventional machining center.”

But what if you don’t have the budget to buy a new set of machines? One approach is to add intelligence, such as smart sensors, to older machines. This approach also fits into sustainable development and the circular economy of the industry.

Companies like VERMOT AUTOMATION and ROBERT & SCHNEIDER SA, for example, have completely retrofitted a Tornos M7 machine. They have added sensors and automation systems found on conventional machines, which improve the manufacturing process and productivity.

Another example is the company GF Machining Solutions, which specializes in electroerosion. The company has created an intelligent spark protection system that exploits rapid and precise signal acquisition and real-time data processing from the sensor electronics. Its intuitive engineering assesses the position of each discharge between the wire and the workpiece by analyzing the concentration compared to a defined threshold. If this threshold is exceeded, the device automatically adjusts the spark energy to prevent wire breakage and maintain optimal cutting speed.

“So, all production technologies can benefit from intelligence for results that lead to a better understanding of processes to further improve productivity or user safety.”