With a focus on plastic intelligence, artificial intelligence (AI), and circular economy principles, igus aims to revolutionize the manufacturing paradigm. We spoke with Selina Pappers, in charge of public relations at igus to talk more about what the company will showcase at Hannover Messe 2024.

At this year’s edition of Hannover Messe, igus will present three key themes that underscore its commitment to innovation and sustainability: plastic intelligence, an AI-powered application, and initiatives promoting environmental responsibility.

1/ Superwise®, igus’s Smart Plastics Service

With their new plastic intelligence digital service, Superwise®, igus aims to revolutionize product performance and reliability. The concept involves integrating sensors into their energy chains and plain bearings to provide predictive maintenance and condition monitoring. This allows businesses to proactively address operational challenges and optimize production processes.

For Selina Pappers, in charge of public relations at igus,

“In essence, the sensors are designed to detect any issues with the product, such as malfunctioning or foreign objects that may have entered the energy chain, causing it to stop working. In such cases, the machine can either halt automatically or alert the operator, prompting them to take necessary action or replace the faulty component.”

Superwise includes an online dashboard accessible to their clients, providing comprehensive insights into all the products they use. Through this dashboard, clients gain access to vital information such as the current condition of each product, its anticipated lifespan within the machine, and when replacements may be necessary.

“Additionally, we offer proactive monitoring services, alleviating concerns for clients who may have limited manpower or resources to continuously oversee their machinery. We notify clients of any impending issues, allowing them to address maintenance or replacements on time without the need for constant oversight. We aim to simplify machine operation for our clients, ensuring they can focus on their core tasks without the burden of constant maintenance concerns.”

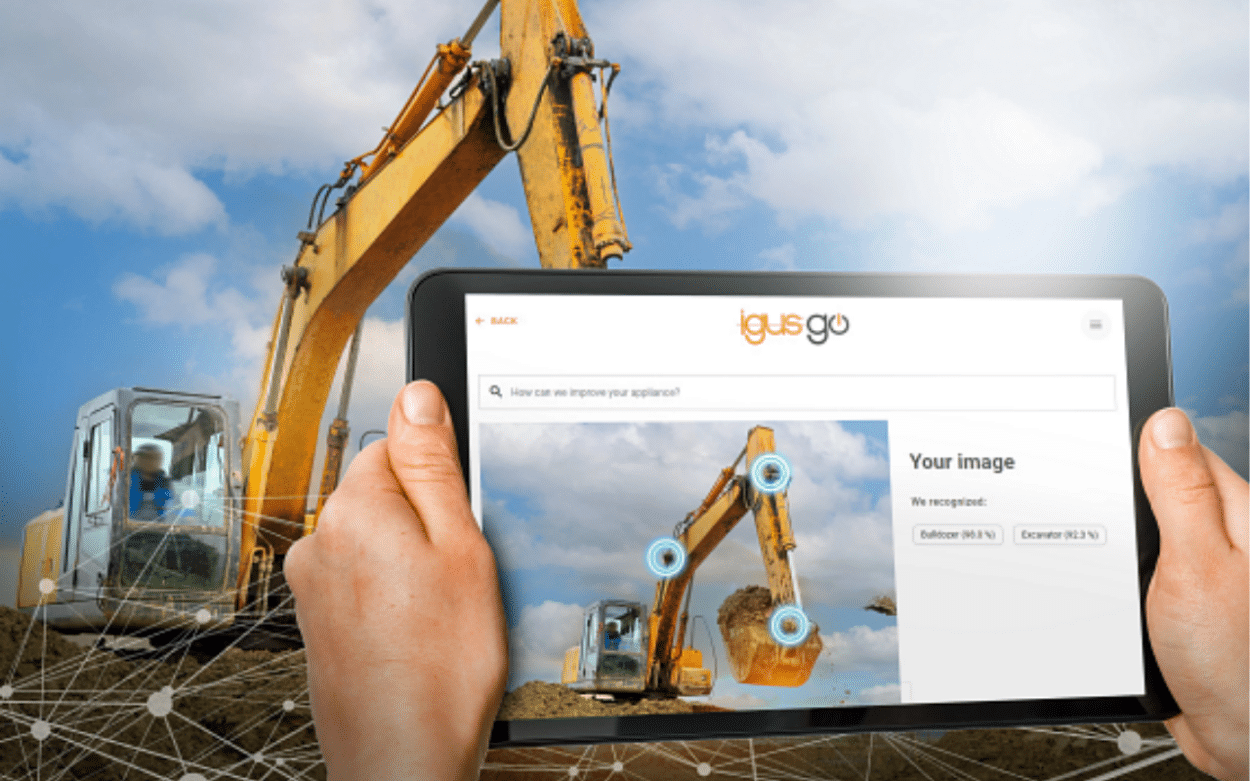

2/ igusGO: An AI-powered App

igus developed an AI-powered app, igusGO, to provide users with personalized recommendations tailored to their unique needs including product selection and application optimization.

“For example, clients may possess equipment like a tractor without knowing the full extent of where they could integrate igus products. With our app, clients can simply snap a photo of their machinery, and the app’s advanced algorithms swiftly identify potential areas for improvement. For instance, if a tractor is photographed, the app analyzes the image and suggests suitable igus products, such as linear guides, for various components like the cabin where the driver sits.”

Moreover, the app offers customizable filters, allowing users to refine their search based on specific criteria like noise reduction or moisture absorption.

“Once suitable products are identified, users can seamlessly navigate to our online store to place orders or gather further details. Additionally, our online tool provides insights into the longevity of each product within the client’s application, leveraging data collected from our extensive test laboratory.”

Introduced at last year’s Hannover Messe, the app has rapidly evolved to include nearly 600 different applications, ranging from bicycles to cranes. Through ongoing machine learning, the app continually expands its database, ensuring it can accurately identify a diverse array of machinery.

For Selina Pappers, the integration of artificial intelligence streamlines the process for clients. It offers them a quick and intuitive solution to enhance their applications and transition to lubrication-free operations.

The company says that depending on the application, implementing lubrication-free solutions could result in substantial cost savings, ranging from €7,000 to €14 million annually.

“These savings primarily stem from the elimination of expenses associated with purchasing grease or oil for use in your machinery. By transitioning to our lubrication-free products, clients can significantly reduce their operational costs while ensuring optimal performance and efficiency.”

3/ Circular Economy and Sustainable Plastics

igus is making products in plastic. Last year, they presented the first energy chain completely made out of recycled plastic.

“We are aware that as a plastics producer, we also want to contribute to a circular economy of plastics. Plastics is an important raw material, and it can be used for a lot of things as we show with our products. But we also know that we have to use it responsibly and at least try to reuse it as often as possible. This is why we are working with partners.”

One of their partners is a UK company, Mura Technology. They have developed a process for chemical recycling so they can make oil out of used plastic waste. And they are just starting to operate the first plant at the beginning of this year.

Another partner is German start-up Cirplus which operates an online platform for trading used plastics.

“While Cirplus focuses primarily on standard plastics, our collaboration aims to expand the scope by incorporating our expertise in technical plastics through our platform, Chainge. By combining our knowledge and resources, we can offer clients the opportunity to utilize our online platform to recycle their old products, such as energy chains or other components, regardless of their origin.”

Their recycling initiative is indeed not limited to igus products; they accept items from other companies.

“Upon receiving these materials, we engage in the recycling process, transforming them into high-quality recycled materials through re-granulation. These recycled materials are then made available on our platform for purchase, providing an eco-friendly alternative for companies looking to incorporate sustainable materials into their production processes.”

igus will be present at Hannover Messe, Hall 6, Stand E26