Greenhouse gases in the atmosphere make life on Earth possible. Yet activities such as burning fossil fuels, deforestation, and livestock farming are adding to these gases, resulting in rapidly increasing global warming. It is vitally important that there is a rethink in our energy sector so that we can move away from using fossil fuels in the long run and switch to sustainable, environmentally friendly alternatives.

Content provided by H2pulse / KELLER Pressure

The use of hydrogen as an energy carrier is currently expected to play a key role in the energy transition.

It can be used to store excess renewable energy generated by solar panels or wind turbines, for example. Unlike electric batteries, this method of storing energy produces zero waste. Moreover, electric batteries unfortunately lose storage capacity over time. As a result, hydrogen tanks are much better suited for storing large amounts of energy.

The hydrogen stored in the tanks can be converted back into electricity using a fuel cell system. Here, electricity, heat, and water are produced when hydrogen bonds with oxygen in the air, all without producing any carbon dioxide emissions. The converted electricity can then be used to power various applications, ranging from stationary and industrial equipment to mobile appliances. This means that fuel cell systems are an important part of the energy chain.

Hydrogen is the smallest molecule on Earth. It can permeate almost anything and is highly flammable when it comes into contact with the air. This makes it extremely important to prevent hydrogen tanks from leaking or to detect any such leaks at an early stage.

A Portable Leak Detection System

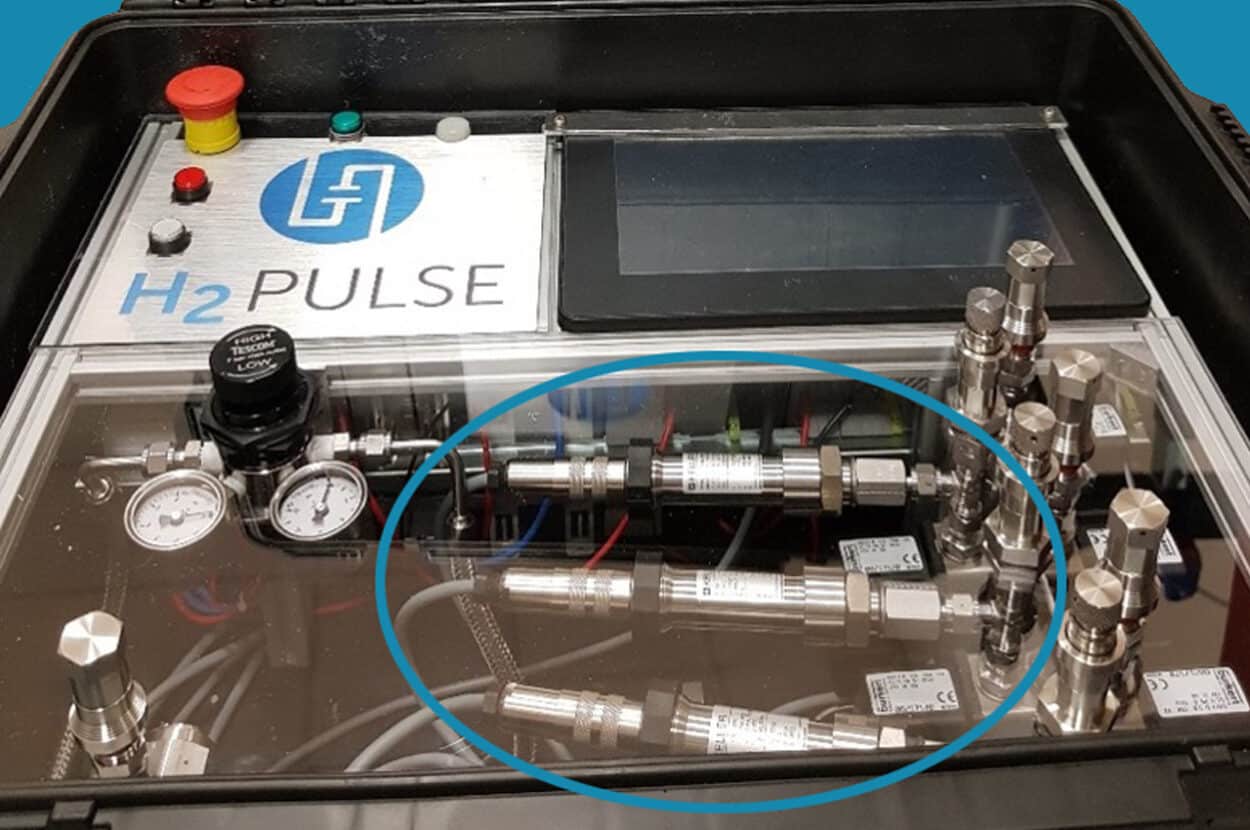

H2PULSE has developed a leak detection system for fuel cell systems, with the help of a grant from the Occitania region of France. The system has been reduced to the size of a suitcase and is therefore portable.

The leak detection system works on a simple principle. The fuel cell in need of testing is attached to the leak detection system via a standard plug-in connector. Hydrogen fuel cells have three channels: one for air (oxygen), one for hydrogen, and a cooling channel. Each of these channels connects individually to the H2PULSE system.

While the fuel cell is not running, a gas flow is connected to the fluidic chain that feeds the three channels. The tests are carried out independently of each other – first using nitrogen, then using hydrogen – to detect any leaks in the system. The cooling channel serves only to cool the fuel cells, which heat up during use.

The Pressure Sensors

KELLER 33X and 21Y pressure sensors measure the pressure at the fuel cell inlet and outlet. The measurements are recorded on an ongoing basis throughout the process and are displayed on-screen in real-time, which ensures continuous monitoring. A loss in pressure indicates that there is a leak in one of the three flow channels. The high degree of accuracy of KELLER pressure transmitters means that they can detect leakages in the smallest non-leak-tight areas, ensuring that fuel cells remain safe to use.