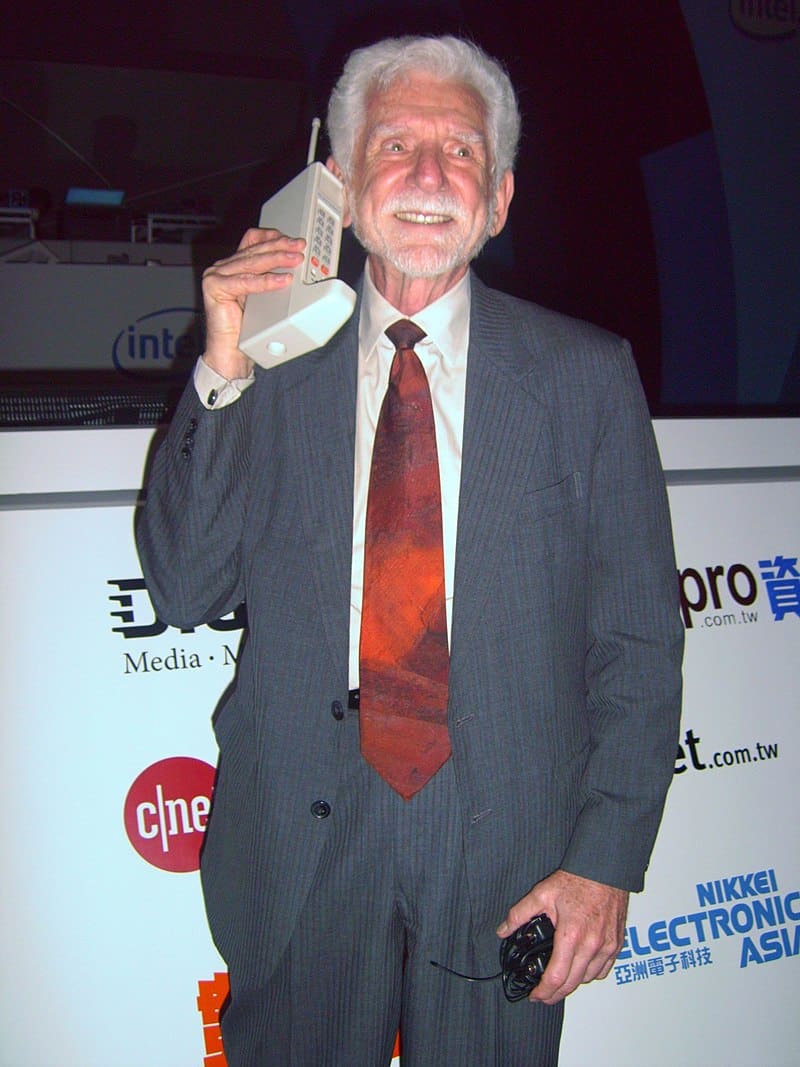

On April 3rd, 1973, Martin Cooper made the first-ever mobile phone call from a New York City street on a device he had created, the Motorola DynaTAC. The call was made to AT&T, Motorola’s rival telecommunications company, and lasted only 20 seconds, but it marked the beginning of a revolution in the way we communicate. This revolution has an impact not only our personal lives but also on industry.

In an interview with Motherboard in 2015, Martin Cooper, an engineer at Motorola, tells how this first call in history was made. It was in 1973, on the 6th avenue in Manhattan, New York.

“I’m with a journalist and I have to make an impression on this guy. And I thought, you’re not gonna take a chance and call Joel Engel, who’s my counterpart and nemesis at AT&T. So I picked up the phone and dialed his number. Amazingly he answered and I said, “Hi Joel, it’s Marty Cooper.” “Hi Marty”, he says. I’m calling you from a cell phone. But a real cell phone. A personal hand-held portable cell phone. Silence on the other end of the line. I suspected he was gritting his teeth. But he was polite, we finished the call. And that was the first public cellular telephone call.”

A Brick-like Cell Phone

From what Martin Cooper said, the idea for the cell phone came from seeing “Star Trek”’s Captain Kirk talking into his communicator. But there was also a competition going on between Motorola and AT&T which had just developed car phones.

The DynaTAC was a bulky, brick-like device that weighed over 1 kg and was 22 centimeters long. It had a battery life of just 35 minutes and 10 hours were needed to charge it.

Despite its limitations, the DynaTAC was commercialized in 1983. The cost of the device was equivalent to over $10,000 in today’s currency ($3 995 at the time).But he paved the way for future innovations in mobile technology.

Today, smartphones are an integral part of our daily lives. They remain a device for communication but with their powerful processors and high-resolution screens, they have also become so much more. They have found a place on the factory floor and in industrial settings.

Smartphones on the Factory Floor

Modern smartphones are now equipped with a range of sensors, including accelerometers, gyroscopes, and GPS, that can be used for a variety of industrial applications.

Smartphones can be for example used to operate a plant. Various software developers have designed human-machine interface (HMI) applications allowing operators to safely operate equipment like machine tools from a remote location using their smartphones or tablets.

RELATED ARTICLES

Regarding maintenance and repair operations, workers can use their smartphones to access equipment manuals, record maintenance data, and troubleshoot issues. This can improve efficiency and reduce downtime, as workers no longer have to leave the factory floor to access important information.

In 2017, we interviewed Iain Mackay, chief operating officer at Petrotechnics, a consultancy and software provider for oil, gas and other industries. For him, mobile apps have a significant advantage for engineers as they provide access to a plethora of information before entering hazardous environments.

“If you have a breakdown on a gas compressor that requires human intervention, an engineer cannot just wander into the field and fix it. They need to know the relative state of processes, environment and equipment around them.”

At that time, Mackay claimed that using a mobile app to consolidate information is more efficient than providing a paper copy. Engineers can access essential safety procedures, historical records of similar work, and a breakdown history of the component. They can also obtain real-time updates on the asset’s integrity, making the app a practical tool. The benefits of mobile devices, apps, and backend software are not limited to high-risk maintenance environments. Access to data from multiple sources, including remote sensors and historical records, can improve operations in various industries.

RELATED ARTICLES

Smartphones are also being used in logistics and supply chain management. Delivery drivers can use their phones to track shipments, monitor inventory levels, and communicate with their teams. This can help companies streamline their operations and improve customer service.

Smartphones are also used for quality control and inspection. Workers can take photos, record videos, and capture data in real time with their devices. This can help identify defects or issues early on, reducing waste and improving product quality.

Another use case for smartphones in industry is in training and development. Workers can access training materials and video tutorials on their phones, allowing them to learn at their own pace and on their own schedule.

Smartphones have come a long way since Martin Cooper made the first mobile phone call 50 years ago. From personal communication devices to valuable tools on the factory floor, smartphones have revolutionized the way we live and work. As technology continues to advance, we can expect to see even more features and capabilities added to our mobile devices, from augmented reality and artificial intelligence to foldable screens and 5G/ 6G connectivity.

![Image [BUYING GUIDE] How to Choose the Right Laboratory Stirrer?](/wp-content/uploads/sites/3/lab-320x213.png)