French start-ups are entering the biotechnology sector. From synthetic biology to green chemistry, the Frenchies are exploring new cutting-edge technologies that could be game-changers for industry. We selected five of these companies.

Abigail Saltmarsh and Chris McCullough contributed to this article.

According to consulting firm McKinsey, France is favorably positioned in several high-tech sectors that are crucial for future competitiveness. These include artificial intelligence, quantum computing and biotechnology. More specifically, France is even among the top three European biotech hubs, along with Germany and the United Kingdom.

It is therefore not surprising to see more and more French companies and start-ups exploring new cutting-edge technologies. We selected 5 of them specializing in synthetic biology, green chemistry and gene editing.

1/ Algentech

Algentech was created in 2009 near Paris and specializes in synthetic biology in plant cells and microalgae for multisector applications, using plant cells as green factories. The company was recently awarded a grant by the European Space Agency to look into the future production of plants that are resistant to perchlorate and radiation.

The company’s breakthrough in chloroplast technology could be of interest to many industrial sectors in search of sustainable bio-based production platforms including biopesticide production, says Dr. Isabelle Malcuit, CSO of the company:

“We are currently producing environmentally friendly, natural pesticides of plant origin. We are also focused on phytoremediation [using plants to extract and remove elemental pollutants] of soil that has been contaminated with toxic compounds.”

For the cosmetic industry, the company is delving into the production of collagen and squalene for cream formulation.

“We are also currently exploring ways to produce different compounds for formulation of vaccine adjuvant and enzymes for biofuel and biogas production from agricultural waste.”

Algentech also has a project looking at providing efficient and low-cost production of hydrogen from plant biomass.

READ MORE

2/ Micropep

Micropep was founded in 2016 as a spin-off of LRSV, the Plant Research Laboratory at the Centre National de la Recherche Scientifique (CNRS) and Toulouse University. The company has recently raised €8.75 million to develop a micropeptide-based biofungicide that could replace chemical pesticides.

Micropeptides are short natural peptide molecules that target and regulate plant genes and proteins. They are generally made of 10 to 20 amino acids.

Micropep’s solution involves the pulverization of micropeptides on the plants. This will improve the properties of the plants, without ever altering their DNA as they only target the plant’s RNA.

They also naturally and rapidly disintegrate into soils without causing any harm to the environment and to people.

READ MORE

3/ Gene & Green

French company Gene & Green TK focuses on enzyme-based disruptive technologies for the agricultural, environmental, and medical sectors. Their objective is to develop organic alternatives that are more effective than traditional chemistry for a multitude of sectors including water processing, plant protection, and neurotoxic substances decontamination.

David Daudé, Chief Executive and Scientific Officer told us more about VesuBACT, the cocktail of enzymes they developed:

“Our enzymes are issued from living microorganisms, have been optimized with enzyme engineering techniques and are produced in bioreactors using biotechnological fermentation processes in bacteria. VesuBACT aims at inhibiting bacterial virulence and biofilm formation while not selecting for resistance.”

Conversely to antibiotics and biocides, VesuBACT does not alter the survival of bacteria but targets the communication system they use to regulate the virulence process.

“By turning the communication process off, VesuBACT decreases bacterial infections in a sustainable way.”

The company also developed VesuTOX, another set of enzymes that are able to degrade chemical warfare nerve agents (sarin, VX, Novitchoks) very quickly without toxicity nor environmental impact.

4/ Pili

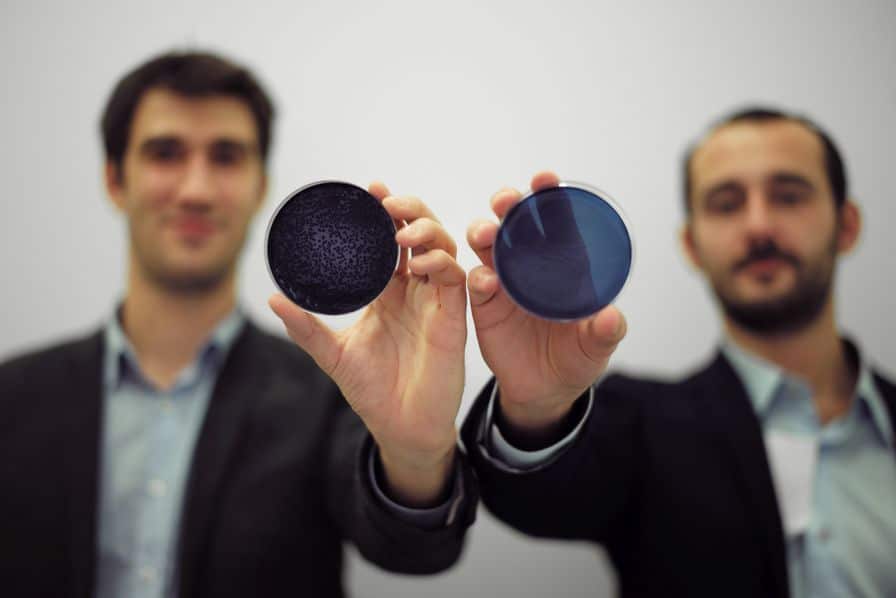

French company PILI aims to tempt industries using textiles, paints, coatings, inks, and polymers, towards more environmentally friendly processes. The company produces biobased dyes and pigments via hybrid processes combining fermentation and green chemistry.

The company’s goal is to radically change the textile industry, reducing its reliance on synthetic dyes as well as the huge amount of water pollution produced by dyeing facilities, explains CEO Jeremie Blache:

“These industries consume most of the colors produced in the world and thus represent the main sources of CO2 emissions. This is why we want to change the way we make them and get rid of petroleum by-products and hazardous chemicals that are necessary today.”

Their technology is based on microbial enzymes that are re-engineered. Each enzyme has genes that are integrated into bacteria which creates cell factories. The bacteria are then grown in water-based bioreactors and fed with sugar. This fermentation process leads to the creation of billions of microorganisms that are all producing sustainable pigments.

5/ Carbios

French firm Carbios employs biotech to tackle plastic waste. For Deputy CEO Martin Stephan,

“Our enzymatic recycling process uses an enzyme capable of specifically depolymerizing the PET (polyethylene terephthalate) contained in various plastics or textiles. Current thermomechanical recycling processes have limitations: only clear plastic can be recycled in closed loops, with a loss of quality in each cycle, making it difficult to obtain new products from 100% recycled PET.”

Thus, complex and soiled plastics are very difficult or impossible to recycle.

“Unlike conventional processes, our innovation allows infinite recycling of all types of PET waste as well as the production of 100% recycled and 100% recyclable PET products, without loss of quality.”