From premium mineral water transport to small home appliances and fresh produce, DS Smith continues to transform industrial packaging with three new 100% fibre-based solutions developed for Alpine Water GmbH, BSH Nazarje, and Famifarm Oy. These innovations embody the group’s ambition to “rethink packaging for a changing world” by combining logistics performance, sustainability, and circular design.

Alpine Water GmbH: Protecting Glass with Cardboard

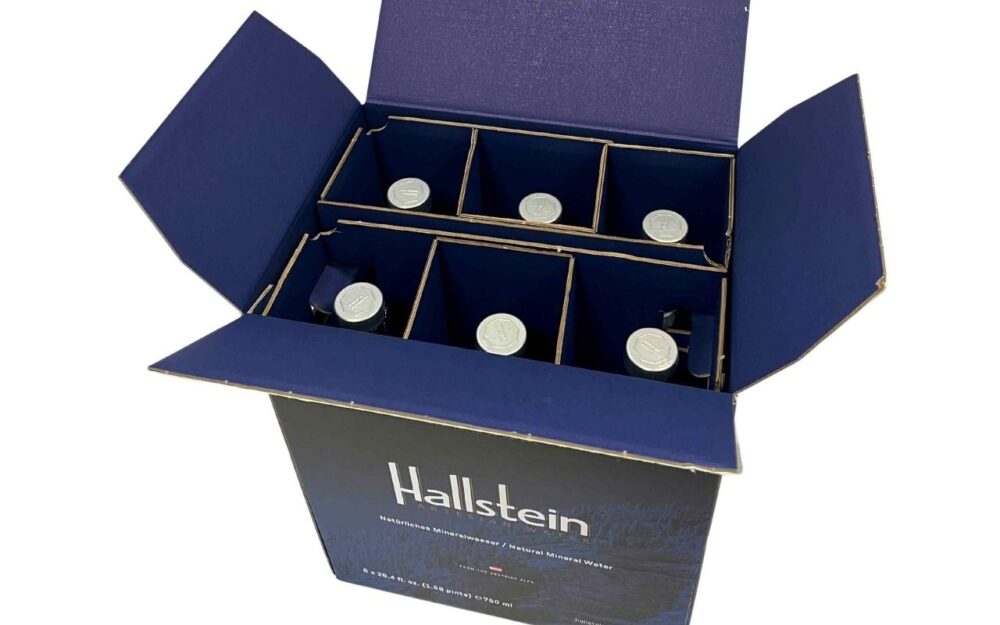

In partnership with Alpine Water GmbH, producer of Hallstein artesian mineral water, DS Smith has designed an e-commerce packaging solution made entirely from corrugated cardboard to replace polyethylene (PE) foam inserts. Each box can hold up to six 750 ml bottles, expandable to 18 depending on logistics needs. Tested to withstand impacts during international shipping, the new packaging doubles assembly speed on production lines while reducing transport costs.

The project relies on DS Smith’s Circular Design Metrics (CDM) and TCO Pack Tool to measure environmental and economic gains. The result: a compact, aesthetic, and recyclable design that optimizes the supply chain and lowers overall carbon footprint.

“We’ve created a robust, sustainable, and versatile solution that protects our premium water while reinforcing our brand identity,” said Alexander Muhr, Managing Director of Alpine Water.

BSH Nazarje: Ending Polystyrene for Blenders

In Slovenia, DS Smith has partnered with BSH Nazarje, part of the BSH Home Appliances group, to develop the DS Smith Universal Protection for Household Blenders. This corrugated cardboard solution replaces the expanded polystyrene (EPS) inserts used for Bosch blenders—eliminating up to 340,000 plastic pieces per year.

The innovation, called Safe Shell, protects three different blender models while reducing packaging time and facilitating integration on existing production lines. Fully recyclable, it requires no changes to cartons or pallets already in use.

“With DS Smith, we’ve proven that efficiency and sustainability can go hand in hand,” said Rok Štifter, Director of Shared Development Services at BSH.

The project was nominated for the 2024 Packaging Oscars in Slovenia, underscoring the growing adoption of fibre-based alternatives in the home appliance industry.

Famifarm Oy: Speeding Up Fresh Herb Unpacking

In Finland, DS Smith and Famifarm Oy, the national leader in potted herbs and salads (brand Järvikylä), have developed a recyclable, quick-opening box with an integrated flap. This ergonomic design allows unpacking up to four times faster than previous solutions while making it easier to fold and recycle boxes after use.

“Our retail partners save valuable time on the shop floor while benefiting from improved brand visibility,” said Jussi Loimusalo, CEO of Famifarm.

Developed by designers Jyrki Petrelius and Veli-Matti Karvonen, this innovation demonstrates DS Smith’s expertise in creating packaging designed for automated packing lines and retail logistics.

According to Jyrki Petrelius, Creative Design Specialist at DS Smith:

“This packaging was designed for automated packing lines and aims to improve the operations of our customers’ customers—retailers and point-of-sale outlets. It’s versatile enough for large and small stores alike. The packaging protects fresh products as before, but now unpacking is much faster and easier.”

A “Now and Next” Strategy for a Circular Economy

Operating in 34 countries, DS Smith continues to advance its “Now and Next” strategy, focused on reducing plastic, optimizing circularity, and creating value throughout the product life cycle. These three collaborations—in the food, home appliance, and fresh produce sectors—demonstrate the group’s ability to replace fossil-based materials with high-performance fibre solutions adapted to complex, global supply chains.

These projects show how innovation in circular design can unite sustainability, productivity, and brand identity,” concludes Andreas Koch, Head of Design & Innovation at DS Smith.

Read also our other stories on packaging and sustainability

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)