At the Paris Air Show 2025, Siemens showcased its full digital engineering arsenal—from design and simulation to immersive reality—supporting JetZero’s ambitious aircraft and the future of aerospace innovation.

As the aerospace industry navigates mounting decarbonization demands, skyrocketing R&D costs, and a surge of startup-driven disruption, the Paris Air Show 2025 offered a clear snapshot of its future. Among the key industry players driving this transformation is Siemens, whose deep digital capabilities are helping reinvent how aircraft are conceived, engineered, and brought to market.

We spoke with Todd Tuthill, Vice President for Aerospace, Defense and Marine at Siemens Digital Industries Software, as well as engineers from Siemens France, who demonstrated how these tools are being deployed today in real-world projects—most notably the revolutionary JetZero blended wing body aircraft.

A New Era for Aerospace Engineering

JetZero, an American startup supported by the U.S. Air Force, is attempting what has never been done before: to bring a blended wing body aircraft to commercial service by 2030, with a first flight in just two years.

“To do something this innovative, you can’t rely on old processes,” Tuthill explained. “JetZero is building everything from a clean sheet using the full Siemens digital stack—from design to simulation to factory automation.”

This full-stack approach includes Siemens’ Xcelerator portfolio—an integrated suite of tools covering mechanical and electrical design, PLM, simulation, factory planning, smart infrastructure, and beyond. According to Siemens, JetZero is becoming a showcase factory for their comprehensive toolset.

Inside the Digital Design Process

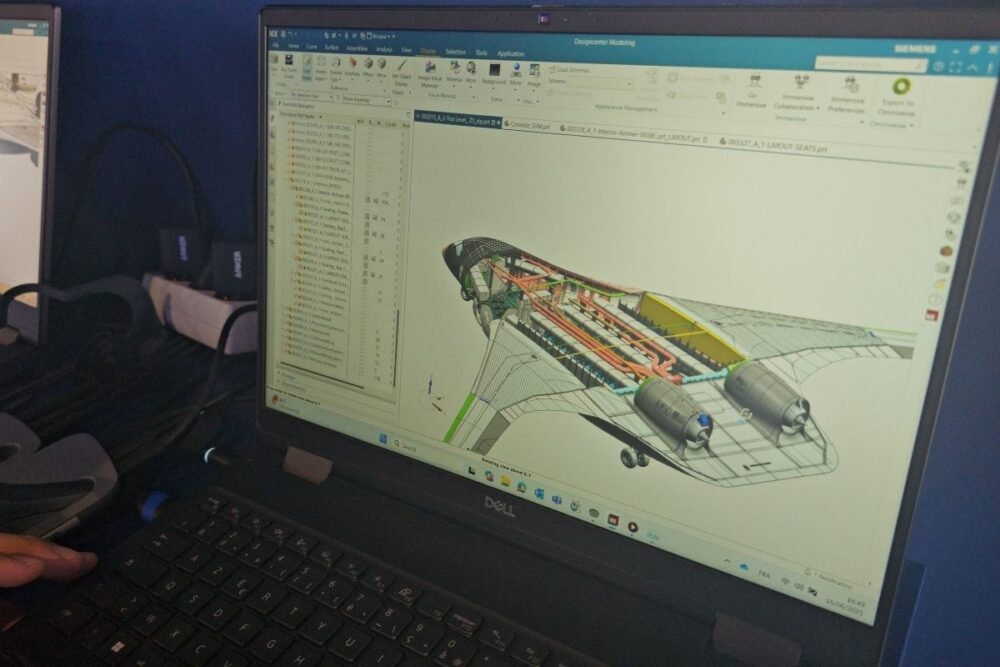

At the Siemens booth, engineers offered a deeper look into how this futuristic aircraft is actually being designed. Using NX, Siemens’ flagship CAD environment, visitors saw the JetZero model in a fully structured digital environment, with an interactive design tree that breaks the aircraft down component by component.

“This is where the design team begins—right here in the model tree,” explained a Siemens engineer. “Each domain—from structural engineers working on the fuselage, to specialists handling cabin layout—works from this same unified digital mock-up.”

This collaborative, multi-domain approach ensures consistency and drastically reduces integration errors.

To push the experience even further, Siemens demonstrated immersive virtual reality using a Sony headset that allowed stakeholders to walk through the aircraft at full scale.

“You can see the interior, feel the volume, and evaluate ergonomics before any physical mock-up is ever built,” the engineer said. “It’s a game changer.”

Why JetZero Chose Siemens

While multiple companies offer engineering software, Siemens stands out for its deep integration, AI leadership, and commitment to industry-specific innovation. Strategic acquisitions—like Altair, Mentor Graphics, and CAE specialists in Europe—have helped the company build what Tuthill calls “the most comprehensive digital twin ecosystem in the world.”

“They chose us because we don’t just offer tools—we offer an integrated platform,” he noted. “JetZero is pushing the limits of AI, AR/VR, simulation, and digital twin technology, and we’re right there with them.”

The comprehensive digital twin is particularly vital. It allows companies to model, simulate, and test aircraft systems digitally, long before a prototype is built. Catching issues in the virtual world, Siemens argues, can save billions.

A Game-Changing Aircraft Concept

The blended wing body design being developed by JetZero promises massive gains in efficiency and sustainability.

“It uses half the fuel of a conventional tube-and-wing aircraft on long-haul routes,” said Tuthill. “That’s half the carbon, half the cost—and a better experience for passengers.”

Besides reduced emissions, the unique shape allows for faster boarding, larger cabin layouts, and potentially quieter cabins. It’s one of the rare engineering concepts, Tuthill noted, that benefits everyone—passengers, airlines, and the planet.

Startups Fueling Disruption

Tuthill highlighted that JetZero is not an outlier. Siemens is working with a growing number of aerospace startups, many of which remain confidential. One that is public is Nautilus, which is developing a next-generation cargo aircraft.

“Startups are hungry for the latest and most advanced tools,” he said. “They want everything: AI, simulation, generative design—all integrated from the start.”

These digital-native companies are not constrained by legacy systems, and Siemens sees them as a key strategic market.

Where the Market Is Going

Looking ahead, Siemens is betting big on multi-domain integration and AI-driven engineering.

“The future is not just about mechanical, electrical, or software—it’s about mechatronic systems,” Tuthill said. “We’re integrating 150 petabytes of engineering data into an industrial AI foundation model to enable generative design through natural language, with AR/VR and agentic AI assisting every step.”

The result: faster development cycles, fewer physical prototypes, and more sustainable designs. According to Siemens, this digital-first approach is no longer optional—it’s the only way to meet today’s timelines and tomorrow’s challenges.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)