AI-powered quality control is helping manufacturers reduce losses while ensuring public safety. With advancements in AI, many players are entering this field with increasingly user-friendly solutions. At Global Industrie, we spoke with Romain Parizot, Project manager at Siemens. The German giant has recently acquired Inspekto, a startup specializing in AI-powered defect inspection.

Ensuring high-quality production standards is a top priority for manufacturers. Traditionally, visual inspection and quality control have relied heavily on human expertise or complex, costly machine vision systems. However, the introduction of democratized AI-based solutions is transforming how industries approach visual inspection and defect detection.

READ ALSO

A User-Friendly AI-Powered Solution

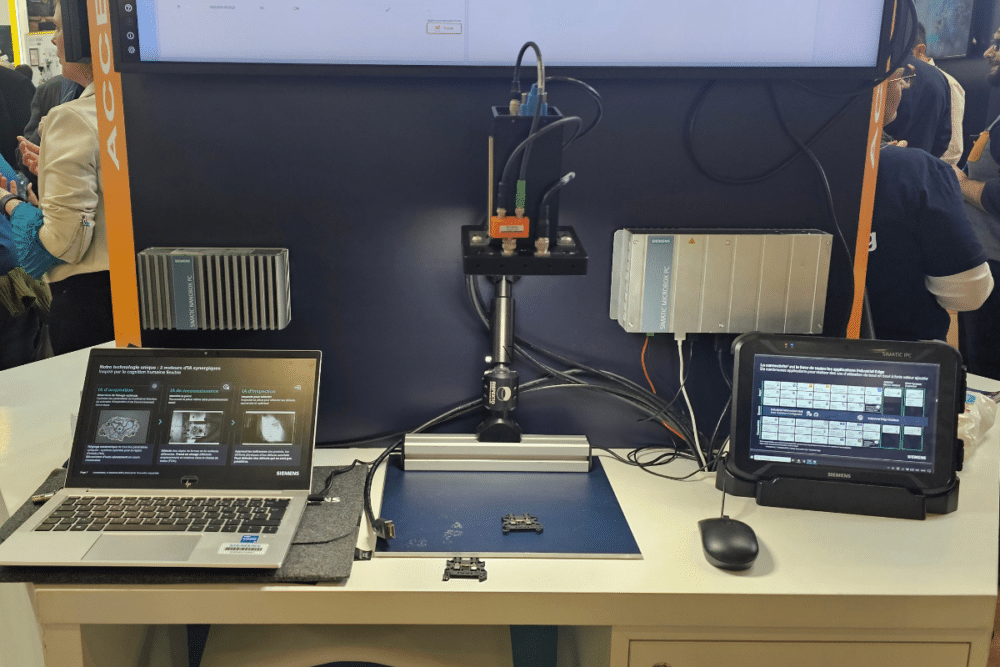

At Global Industrie, the leading French industrial event currently taking place in Lyon, we met with Romain Parizot, Project manager at Siemens, to discuss Inspekto, the embedded AI solution that the German leader has recently acquired.

Inspekto is designed for industrial applications that allows manufacturers to set up visual inspection systems without requiring specialized expertise. Unlike traditional AI-driven inspection methods, which often demand the intervention of data scientists, Inspekto provides an easy-to-use system that can be deployed directly onto production lines.

“Any operator, regardless of technical background, can train the AI model using a single embedded camera and an industrial PC. The system enables users to train their own AI model using as few as 20 defect-free samples. Once deployed, the AI continues to learn and improve by adapting to new defects detected during operation. If a specific anomaly is found, it is automatically added to the model, enhancing its detection capabilities over time.”

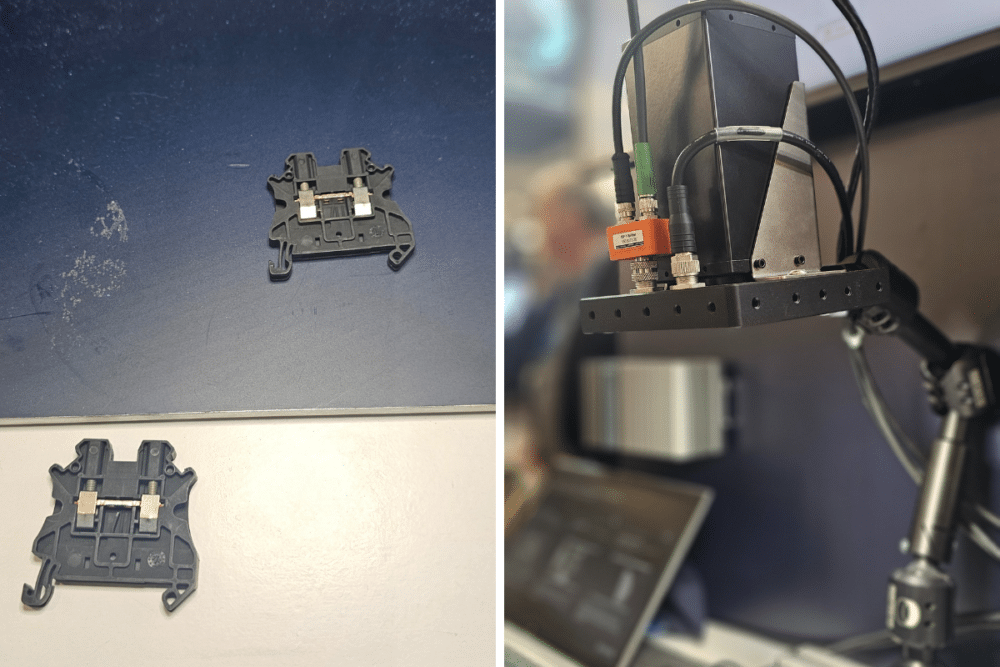

A Wide Range of Defects

Inspekto is capable of identifying a broad spectrum of defects, including imperfections in molded or poorly molded parts, scratches and surface defects on metallic and other materials.

For Parizot,

“AI also makes it possible to integrate a detection model for highly reflective parts, allowing for the attenuation of light reflection from the camera while also detecting molding defects or design flaws on parts with high contrast, such as a black-molded components.

The system is able to inspect different materials, including plastic, metal, and cardboard.

Inspekto is also designed to accommodate a diverse range of production environments, from small components to large automotive parts. The system supports inspections for pieces ranging in size from 3 cm to 1.5 meters.

Seamless Integration with Production Lines

Once a defect is detected, Inspekto triggers an alert that is displayed on a dashboard. The information can also be sent via communication protocols to an automation system, allowing the production line to take immediate action.

“This could mean automatically rejecting defective parts or temporarily halting production for further quality verification.”

The AI does not make decisions regarding production stoppage but communicates with automated control systems, which determine the appropriate response based on predefined rules.

Manufacturers can integrate the system at any stage of the production process:

“It can be upstream, to verify raw material quality, mid-production to ensure proper assembly or for final inspection, to guarantee the quality of finished products before distribution.”

Applications

Inspekto has been available on the market for several years and has already been implemented by major manufacturers. Today, the solution is widely used in discrete manufacturing sectors, including automotive and aviation industries.

Originally developed as a startup, the company was recently acquired by Siemens, enhancing its industrial AI portfolio.

By democratizing AI-based quality inspection, Siemens is paving the way for a new era of industrial automation, where intelligent, self-improving systems ensure higher efficiency, lower costs, and better product quality without the need for extensive technical expertise.