DirectIndustry attended the JIMTOF trade show at Tokyo Big Sight last week and explored the latest innovations in manufacturing. Our industry analyst, Hicham Dhouibi, met with Atsuhiro Yoshinaka, from Japanese manufacturer THK. THK, renowned for its advanced linear motion technology, has developed a TGS Seismic Isolation Module designed to protect machinery during earthquakes.

Are you prepared for quakes? Are your devices well protected in case of an earthquake? At JIMTOF last week, DirectIndustry had the opportunity to discover a range of new technological advancements. THK’s innovative solution for industrial machine protection against earthquake damage is one of them. To gain a deeper understanding of this device, our analyst interviewed Mr. Atsuhiro Yoshinaka. He is the Supervisor of the Mechanical Seismic Isolation Planning Section. Both of them even took part in a demonstration simulating a 6-7 intensity earthquake to experience the effectiveness of the isolation system firsthand.

What anti-seismic products does your company offer, and what are their functions?

Atsuhiro Yoshinaka: “Our focus is on earthquake-resistant technology. We design “partial isolation systems,” which provide earthquake protection for equipment. Our partial isolation systems are specifically designed for the high-precision machinery and equipment found in facilities, especially in the high-tech and manufacturing sectors. Thjese can be semiconductor manufacturing machines and data servers. By isolating sensitive machinery from seismic vibrations, our systems help ensure that equipment remains operational and undamaged during earthquakes.

These systems absorb and dampen seismic shocks, allowing sensitive equipment within buildings to withstand earthquakes and continue operating without damage.

For example, when a major earthquake struck the Noto Peninsula on January 1, 2024, many facilities suffered significant damage. Our partial isolation systems can prevent such damage to critical equipment from happening by reducing the impact of seismic shocks.”

Could you explain the specific features of your partial isolation devices?

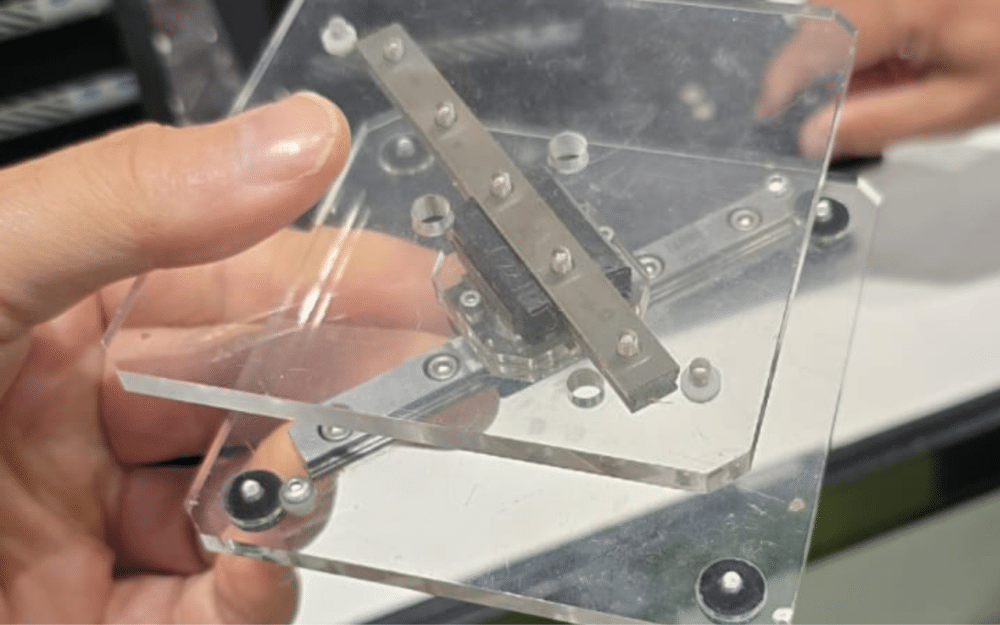

Atsuhiro Yoshinaka: “Certainly. Our main products are linear guides, which are at the core of our seismic isolation systems. The system is based on LM Linear Guide units assembled in a cross shape. This allows the device to achieve precise multi-directional motion up to 330 degrees. Each unit integrates a coil spring and a damper to enhance stability and smoothness.

By combining the coil spring and damper, the isolation device can absorb vibrations and reduce unwanted movement. This setup leads to smoother, more accurate operation and increases the lifespan of both the device and the machinery it protects. This solution is ideal for applications where stable, reliable motion control is essential, such as in sensitive machinery, servers, and data centers.”

Is this a customizable product?

Atsuhiro Yoshinaka: “Yes, our partial isolation systems are highly customizable. Clients provide us with specifications regarding the size, shape, and specific requirements of the equipment needing protection. Based on these details, we design isolation devices that fit each piece of machinery or equipment precisely. While the core technology remains consistent across units, we adjust the dimensions and loading capacities to match different requirements.”

How is the product packaged and delivered?

Atsuhiro Yoshinaka: “Each isolation device is sold as a compact, closed unit. It’s an independent system, designed to be efficient and easy to integrate. You can see examples of these units in our catalog, where each model is available in several standard sizes to fit a range of machinery. For example, we offer a 450 square centimeter unit, which is popular for specific machine tools.”

What are the weight capacities of these isolation units?

Atsuhiro Yoshinaka: “Each unit has a specified load limit. For instance, our standard 50-centimeter square unit can support up to 750 kilograms. For higher load requirements, we can create custom designs. For example, if a client needs to support 1000 kilograms per unit, we can customize the product accordingly. Additionally, by combining multiple units, the load capacity can be significantly increased; four units together can sustain a total load of three tonnes.”

Can you tell us the level of protection this product offers?

Atsuhiro Yoshinaka: “Our isolation units are highly effective at minimizing earthquake impacts, absorbing up to 90% of seismic energy (a 1:10 energy absorption ratio). While we can’t guarantee complete immunity from damage under all conditions, these units drastically reduce the risk of equipment failure or damage. Additionally, if a client provides specific earthquake wave data, we can further fine-tune the design to meet their precise needs, tailoring the product to absorb expected maximum seismic loads.”

What are the key specifications for each unit?

Atsuhiro Yoshinaka: “Key specifications include load capacity, size, and dimensions, along with stroke, weight, and any additional client requirements. These parameters help determine the isolation unit’s compatibility with different equipment and the level of protection it can provide.”

Is the product rated for a specific earthquake intensity?

Atsuhiro Yoshinaka: “Our isolation systems are adaptable to any earthquake intensity. If a client provides us with specific seismic wave details, we can design the unit to perform under those conditions.”

Are there multiple applications for this product, and where are the primary markets?

Atsuhiro Yoshinaka: “Yes, our isolation systems are versatile, making them suitable for protecting machine tools, servers, data centers, and various sensitive equipment. While Japan remains a primary market due to its high earthquake activity, we also see strong demand from Turkey, Taiwan, and the Middle East. Recently, Turkey has become a significant market for us due to a recent major earthquake and the region’s growing manufacturing sector. We also have inquiries from earthquake-prone areas in the U.S., such as San Francisco.”

Do you also offer isolation devices for buildings?

Atsuhiro Yoshinaka: “Yes, but the building isolation systems are developed through a partnership with another company. While we contribute technology and expertise to these solutions, they are not our original products. Our primary focus and innovation lie in partial isolation devices for machinery and equipment, where we offer complete, customized solutions to meet client needs.”

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)