The plastics industry is a cornerstone of modern manufacturing. Plastic is a versatile material used for a myriad of applications. Understanding the different types of plastics is essential for industry professionals looking to optimize their use in various sectors. This article delves into the key types of plastics, their properties, and common applications.

Plastics is a derivative of oil. There are around 10 different categories of plastics. Each type of plastic offers unique benefits and can be optimized for different uses, from packaging and construction to automotive and consumer goods. Understanding the diverse range of plastics and their specific properties is crucial for industry professionals aiming to select the right material for their applications.

1/ Polyethylene (PE)

Polyethylene is the most widely produced plastic. It is available in several forms:

- The Low-Density Polyethylene (LDPE) is known for its flexibility and transparency. LDPE is commonly used in plastic bags, films, and containers. It boasts excellent moisture resistance but has lower tensile strength compared to other forms.

- The High-Density Polyethylene (HDPE) is more rigid and durable than LDPE. HDPE is used in products such as milk jugs, detergent bottles, and piping. It offers excellent impact resistance and is widely recycled.

2/ Polypropylene (PP)

Polypropylene is a versatile plastic noted for its resistance to fatigue and chemical exposure. It is used in a range of applications including automotive parts, textiles, reusable containers, and medical devices. PP is valued for its toughness, flexibility, and resistance to high temperatures.

3/ Polyvinyl Chloride (PVC)

Polyvinyl Chloride is known for its durability and low cost. It comes in two forms:

- Rigid PVC is used in construction for pipes, window frames, and siding due to its strength and rigidity.

- Flexible PVC is utilized in plumbing, electrical cable insulation, and clothing due to its pliability and resistance to environmental degradation.

- It is also widely used in medical settings due to its impermeability to germs.

4/ Polystyrene (PS)

Polystyrene is a hard, lightweight, brittle plastic often used in packaging. It exists in several forms:

- General-purpose polystyrene (GPPS) is used in disposable cutlery (like foam cups), CD cases, and laboratory ware.

- High-impact polystyrene (HIPS) contains rubber, making it more durable and used in applications like appliance housings and toys.

- Expanded Polystyrene (EPS) has insulation properties. It is used in packaging, foam cups, and building insulation.

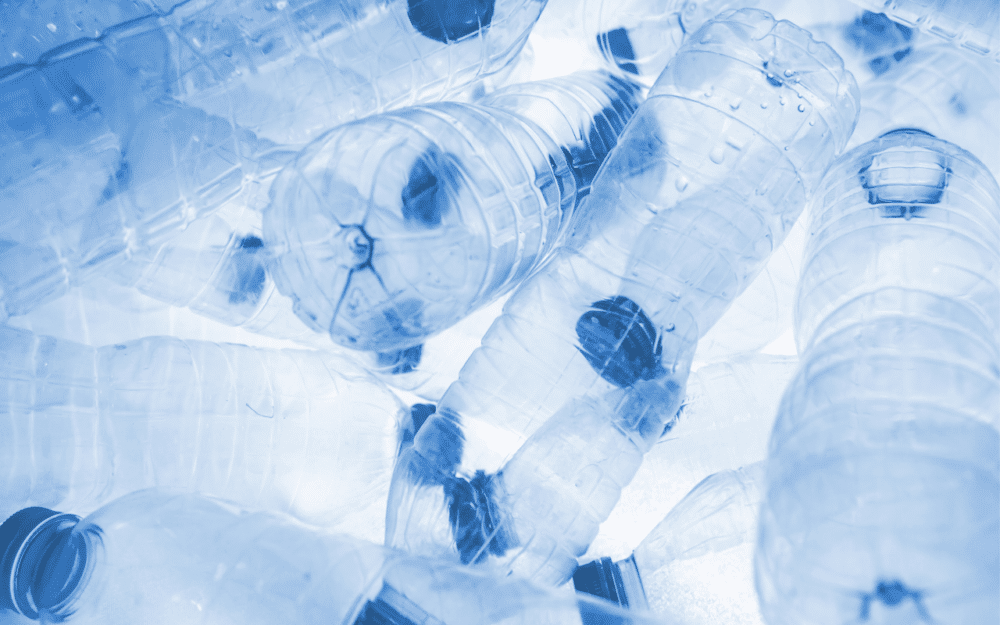

5/ Polyethylene Terephthalate (PET)

PET is commonly used in the production of beverage bottles, food containers, and synthetic fibers. It is valued for its strength, thermo-stability, and transparency. PET is highly recyclable and often converted into products such as clothing fibers and industrial strapping.

6/ Acrylonitrile Butadiene Styrene (ABS)

ABS is a robust, impact-resistant plastic used in automotive components, toys (like LEGO bricks), and electronic housings. It combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber.

7/ Polycarbonate (PC)

Polycarbonate is known for its high impact resistance and transparency, making it ideal for use in eyewear lenses, bulletproof glass, CDs, and electronic components. It can withstand extreme temperatures and is also used to manufacture medical devices and automotive components.

READ ALSO

8/ Polymethyl Methacrylate (PMMA) or Acrylic

Polymethyl Methacrylate is also known as acrylic or Plexiglas. This transparent plastic is a lightweight and shatter-resistant alternative to glass. It is used in applications requiring clarity and durability, such as skylights, advertising signs, displays, lenses, and vehicle taillights.

9/ Nylon (Polyamide)

Nylon is a synthetic polymer used extensively in textiles, automotive parts, and consumer goods. It is prized for its high tensile strength, elasticity, and resistance to abrasion and chemicals. Common applications include fishing lines, gears, and machine parts.

10/ Tritan Plastic

Tritan™ plastic is a type of copolyester developed by Eastman Chemical Company that offers glass-like clarity. It is a good choice for products where visibility is important, such as reusable water bottles, food containers, and baby products. Tritan is highly resistant to impact, compared to other plastics like polycarbonate (PC). It can withstand high temperatures, meaning it is dishwasher-safe and ideal for products that require sterilization.

Tritan plastic is also free from Bisphenol A (BPA) and other bisphenols, addressing health concerns associated with traditional plastics.

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)