DirectIndustry attended Fermob‘s press conference in Paris last week. The company, known for its vibrant outdoor furniture, emphasized the recyclability and dismantlability of its products and introduced its own Product Lifecycle Index (PLC). Additionally, they unveiled their new indoor furniture range.

The French company is renowned for its colorful outdoor furniture. Their metal BISTRO chairs can be spotted worldwide, from Times Square to the Forbidden City in Beijing and, more recently, near the Sydney Opera House in Australia.

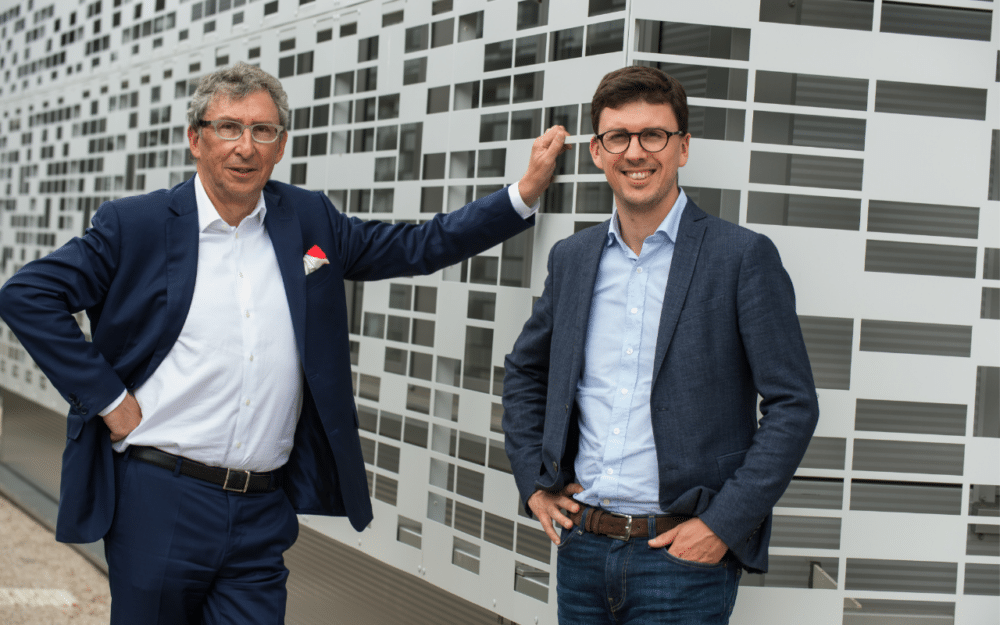

Fermob held an extensive press conference in Paris last week where its leaders, Bernard Reybier, President of the Fermob group, and Baptiste Reybier, CEO, presented the company’s strategic directions. The executives particularly emphasized their commitment to more responsible and environmentally friendly production, focusing on eco-design and product lifecycle. They have developed their own indices for assessing the recyclability, dismantlability, and repairability of their furniture. Another novelty: Fermob is increasingly venturing into indoor furniture.

Commitment

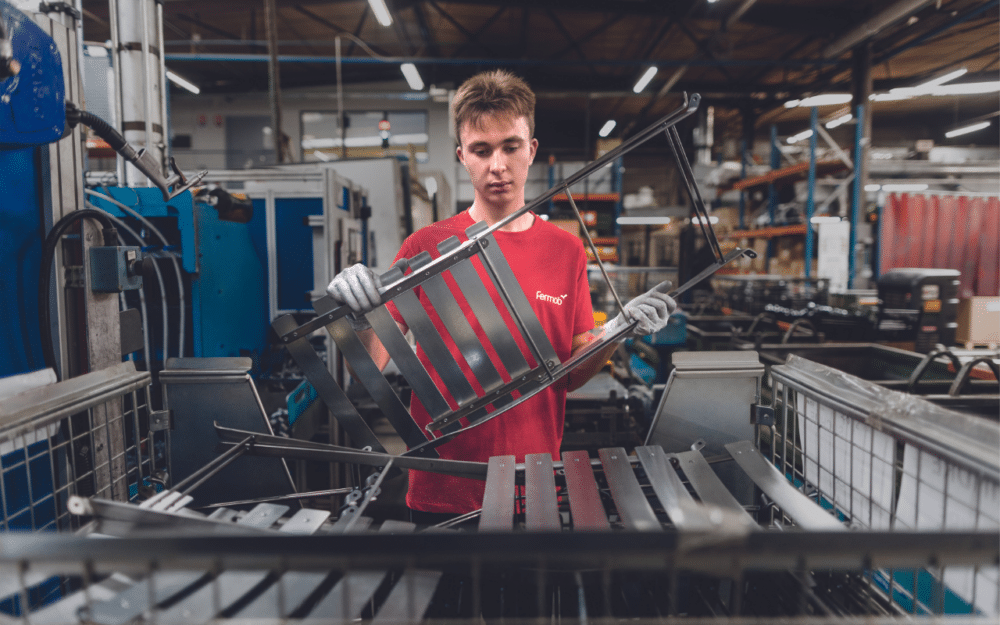

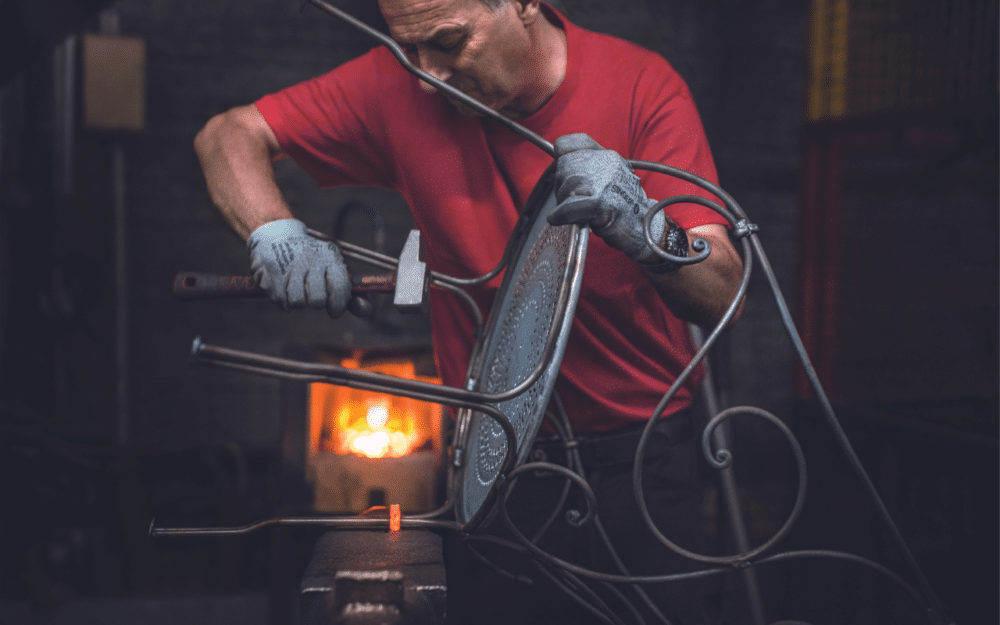

Since 1989, Fermob has been designing outdoor furniture made of metal. From a small family workshop, the company has grown over the years to become a leading brand in the outdoor sector. It has become a lifestyle brand, with its iconic BISTRO chair available in dozens of colors, from honey to acapulco.

According to Bernard Reybier, the company owes this success to its commitment to quality and innovation. As a result, Fermob is one of the few remaining French outdoor furniture companies working with metal, while others have disappeared from the market.

During its press conference, the company emphasized its commitment to aligning with climate and biodiversity challenges.

For Baptiste Reybier, it’s becoming a necessity for companies to move towards more environmentally friendly production processes and products. This commitment is driven by both environmental respect and business concerns.

“I especially think that not having these qualities will quickly penalize companies. We mainly think that if we don’t have this approach, we will quickly be penalized. Because environmental commitment is becoming a purchasing criterion for consumers. So we’re happy to say that we’ve had this policy for thirty years and that it’s an asset.”

Baptiste hopes consumers will increasingly choose Fermob products for their positive environmental impact. So, how does Fermob address climate and biodiversity challenges in its operations and products?

According to Baptiste,

“We first focus on the design and durability of our products. Then, we address the impact on natural resources like water through our processes. We also work on our teams, emphasizing human aspects. We collaborate with our partners. Additionally, we communicate all of this with transparency.

He refers to this approach as the RE concept: renewable, repairable, resaleable, and ultimately recyclable.

“The goal for Fermob is to offer products that are perpetually renewable.”

Eco-Conception: Reduced Material Usage and Extended Product Lifespan

Firstly, the company aims to use less material in its chairs, as seen in the case of the Bistro chairs. They try to design their products and then cut their products in a way that minimizes production materials and waste.

The company has also implemented a zero-discharge paint chain for the past 28 years.

Eighteen months ago, the company launched the Re-Paint project to extend the lifespan of their products. The concept is simple: people can bring in their products for renovation, whether it’s a Fermob table that’s 10 years old or simply to change the colors of newer furniture for a style refresh.

According to Baptiste:

“We have a network of industrial paint applicators located in 34 locations across France where people can bring their products. They will be stripped, repainted, and restored to almost new condition, extending their lifespan considerably. So, we’re really focusing on extending product lifespan, which is highly impactful, as it promotes the concept of truly renewable products. Whether it’s prolonging the lifespan of a worn-out product or encouraging people who change every five years to avoid a new purchase, it helps reduce overconsumption by retaining the same product but adapting it.”

To date, they have had approximately three thousand consultations with a recommendation rate of 98%.

Water Consumption

The company has also reduced its water consumption per product,” continues Bernard.

“Between 2015 and 2020, Fermob reduced its water consumption from eleven liters per product to three point four liters per product. That’s a forty-seven percent improvement.”

Baptiste continues, shifting focus to the carbon footprint. In 2023, they had 71,000 tonnes of CO2, with 98% from scope three emissions.

IREP, IRCY: Two Indices for Repairability and Recyclability

But Fermob wanted to go even further. The company has made efforts to make the majority of their products dismantlable, either to facilitate the replacement of worn parts or for better recyclability.

The company has therefore developed its own repairability and recyclability indexes to get ahead of regulatory demands, as Bernard Reyber explained:

“The reparability indices exist by law for appliances, but there’s nothing similar for furniture, especially outdoor furniture. Therefore, Fermob has established a performance barometer for the repairability, recyclability, and durability of its products.”

The objective is that Fermob’s products are designed to be disassembled, enabling the replacement of worn-out parts and extending their lifespan, all while maintaining their appeal.

IREP

IREP, the repairability index, which ranges from 0 to 2, evaluates product repairability based on three criteria: disassemblability, availability of spare parts, and repair complexity. Applying this index to the entire Fermob catalog reveals that 87% of the products are rated IREP 2 (easily repairable by individuals). This also means that spare parts and consumables are available for replacement.

The idea, as Bernard explains, is that a screwdriver should be the only tool needed.

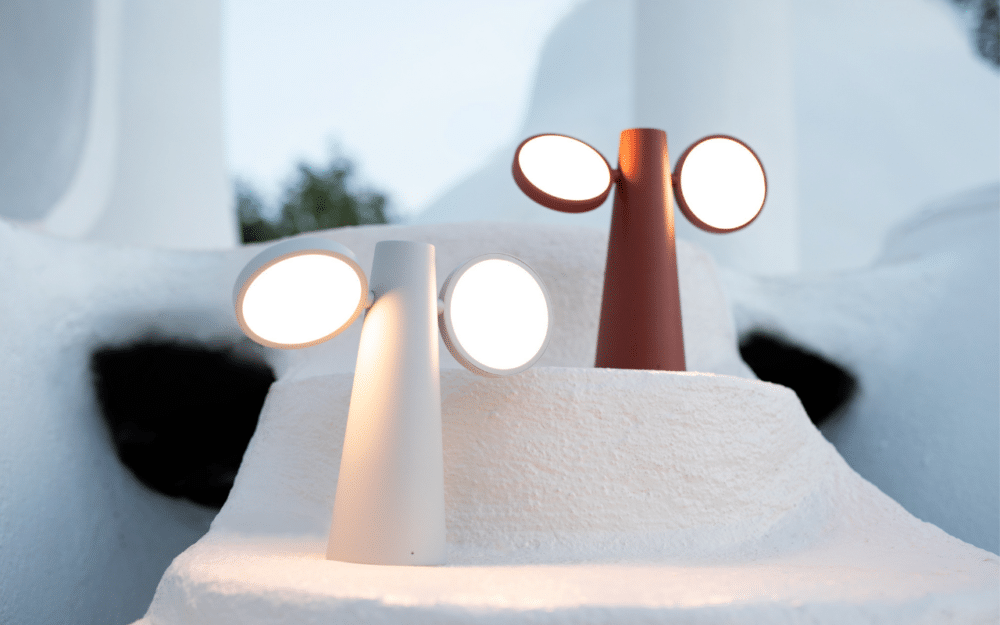

“87% of our products are repairable. Our lights are 95% dismantlable because there is no welding. We managed to convince our Asian electronic card suppliers to manufacture cards with non-welded elements for dismantling and replacement.”

IRCY

The company has also defined its recyclability index (IRCY), which measures the recycling potential of products at the end of their life. This index considers the types of materials used in their composition, the presence or absence of recycling disruptors—such as material separability, and electrical or electronic components—and the maturity of the recycling industry for the relevant materials. This index guides the selection of components for manufacturing new products. Applying this index to the entire Fermob catalog shows that nearly 95% of the products are classified as “fully recyclable.”

Why develop their own indices? According to Baptiste, analyzing the product lifecycle is a crucial consideration for manufacturers today. Products should be designed to be durable over time and recyclable at the end of their lifespan.

According to Bernard, the objective is to share these indices with other players in the sector.

RELATED ARTICLE

From Outdoor to Indoor

Specializing in outdoor furniture, Fermob concluded its press conference with the presentation of products dedicated to interior spaces.

Baptiste remarked,

“We are officially embracing the transition into indoor environments with products designed for indoor use. These products retain indoor-specific features while incorporating elements of versatility, with new materials such as wood and leather in addition to metal.”

They introduced us to the BISTRO chair in French cowhide leather, which utilizes a solvent-free aqueous adhesive, is environmentally friendly, and is durable against stains, aging, and marks. Specifically designed for indoor use, it boasts mineral tanning and a finish that enhances resistance.

Another example is the STUDIE armchair range, initially launched in metal two years ago and now available in durable, sustainably sourced French oak wood for timeless recyclability.

Furthermore, there’s the CALVI table with a Phoenix tabletop. Originally designed for outdoor use with a metal top, it now features a Phoenix tabletop specifically crafted for indoor settings. With easy maintenance, scratch resistance, antibacterial properties, and a soft, silky touch, it’s a testament to versatility and comfort.