Software Advice highlights the major challenges facing supply chain professionals in 2024. What strategies can companies adopt to meet these challenges? Elicia Petit, content analyst at Software Advice gave some insights.

In 2024, supply chain issues are evolving, shaped by a series of emerging challenges redefining them. Three major challenges stand out: sustainability in commerce, investment in cybersecurity, and workforce challenges.

The digitization of the supply chain has become essential for companies seeking to optimize their procurement operations. Investment in this digital transformation can improve logistics processes’ efficiency, visibility, and flexibility, and constitute a crucial competitive advantage.

What technological investments should companies prioritize in the supply chain? How can we ensure workforce stability in the face of supply chain challenges? How can companies adapt their strategy to a context of sustainable development? Software Advice surveyed 200 supply chain and logistics professionals to answer these questions.

RELATED ARTICLE

Supply Chain Cost Optimization

Economic inflation emerged as a major concern for 50% of respondents, reflecting apprehensions about rising costs and pricing pressures. Logistical delays (29%) were also reported as an expected challenge for 2024.

These delays result from a variety of factors. These include transportation bottlenecks, disruptions to global trade routes, and interruptions caused by geopolitical instability.

The companies surveyed recognize the potential of technology to improve efficiency, decision-making, and overall supply chain performance, as well as to reduce costs.

To reduce expenditure, 23% of companies surveyed plan to start negotiating contracts with their suppliers. 62% plan to continue these discussions.

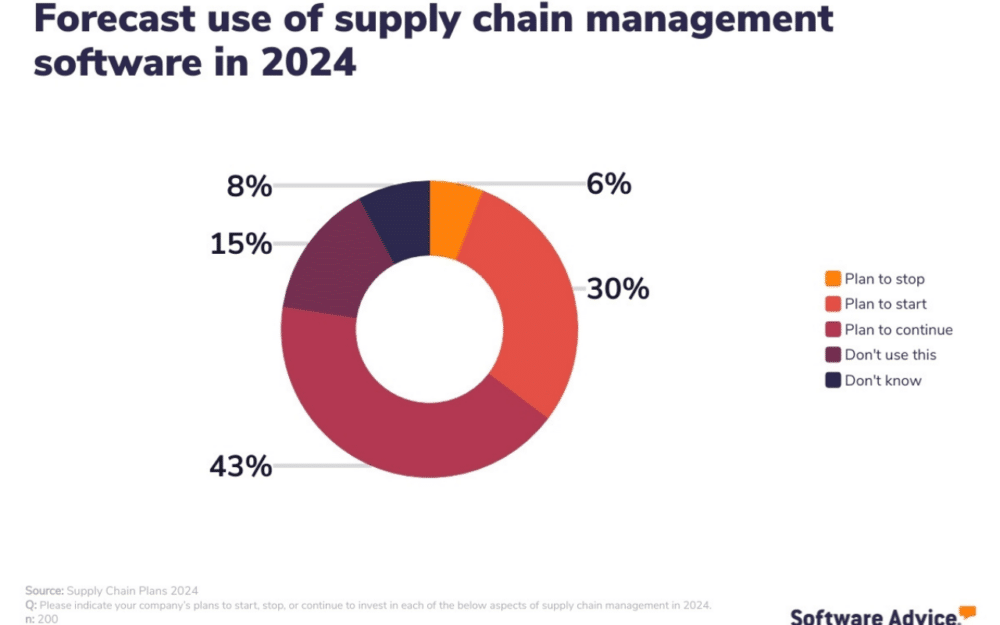

In addition, 30% of respondents plan to adopt supply chain management software. 39% of respondents indicated that 6% to 10% of their 2024 budget would be spent on supply chain technologies.

44% of companies plan to increase their investment in artificial intelligence

Investment in cutting-edge technologies is also part of the plans for almost half the companies surveyed. 46% of the surveyed plan to maintain or start investing in technologies such as advanced cybersecurity. 44% will do for artificial intelligence and the same proportion for advanced data analytics. Each of these technologies can be used to ensure supply chain integrity.

Artificial intelligence (AI) has become a fundamental pillar of supply chain management. It enables companies to automate and optimize their processes, such as demand planning, logistics route optimization, and inventory management. Thanks to artificial intelligence software, companies can anticipate fluctuations in demand and identify market trends.

Cybersecurity is a top priority to protect sensitive data and ensure business continuity. Cyber-attacks can compromise information security, disrupt the flow of goods and jeopardize customer confidence. By investing in cybersecurity software, companies strengthen the protection of their systems and reduce the risk of data breaches.

Data analytics plays a crucial role in optimizing supply chain performance by providing actionable insights from data generated throughout the logistics process. By using data analysis tools, companies can identify trends, predict future demands, and improve operational efficiency.

The impact of a possible cyber-attack worries 25% of respondents

In the last 12 months, 39% of companies have experienced operational disruption due to a cyber attack. Organizations that rely on complex supply chains spanning different geographies and partners are exposed to more cyber threats. With cyberattacks and data breaches on the rise worldwide, investment in cybersecurity measures has become a priority for organizations.

82% of companies want to prioritize their cybersecurity investments to safeguard their operations, reputation and customer trust. Cybersecurity tools are perceived as essential to business success. A significant majority of respondents (84%) recognize their importance (55% consider them “very important” and 29% “rather important”).

To counter these threats, companies can implement rigorous security protocols, and invest in technology and ongoing training programs. Regular awareness-raising and training of employees in security best practices are essential to ensure their involvement in protecting data and systems.

Retaining Skilled Workers

Almost a quarter (21%) of the companies surveyed have faced some kind of sourcing challenge over the past six months due to a shortage of talent. This shortage can be attributed to several factors.

Firstly, supply chains are becoming increasingly complex due to globalization, growing market interconnection, and product diversification.

Secondly, the integration of automation, artificial intelligence, data analysis, or even Blockchain, among other technological advances, is transforming the supply chain. This is creating an increased demand for professionals with expertise in these emerging fields.

Finally, the skills demanded in the supply chain are evolving. Employers are looking for professionals who can understand and analyze data to make strategic decisions and communicate effectively with partners on a global scale. This demand for specialized and versatile skills is contributing to the shortage of supply chain talent.

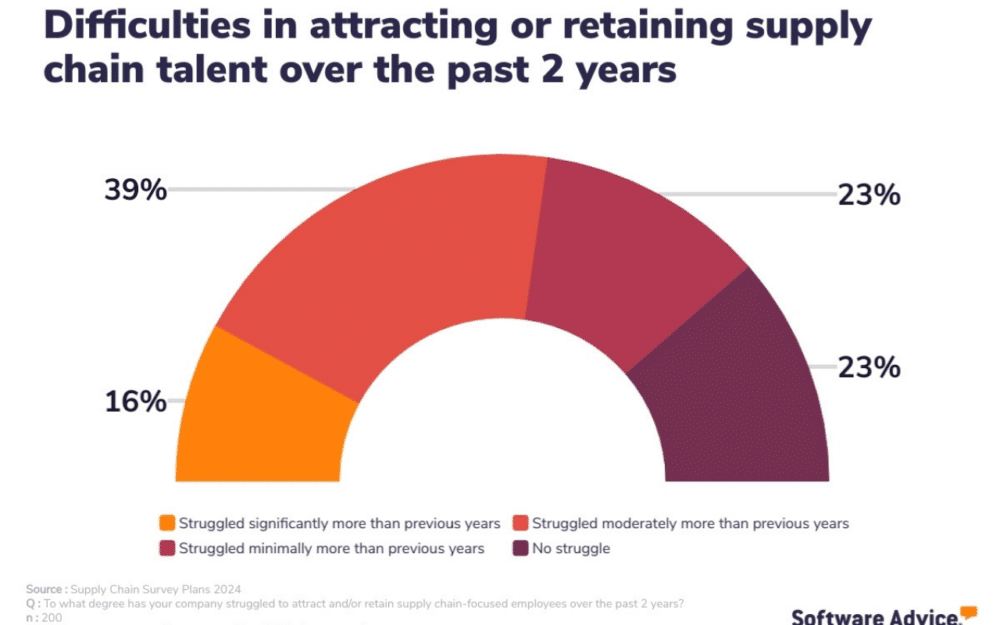

Indeed, 55% of respondents claim to have encountered difficulties in attracting and/or retaining supply chain specialists over the past two years. Of these, 16% have experienced significantly increased difficulties compared to previous years, while 39% have experienced moderately increased difficulties.

How do we deal with this labor shortage?

Companies can improve workforce retention by implementing several strategies focused on professional development, well-being, and employee engagement.

Here are a few key approaches that can help companies retain their employees.

- Expand your technology base: investment in the technology sector and autonomous mobile robots will automate tasks and support the existing workforce.

- Expand career opportunities: training, mentoring and professional development opportunities will enable employees to progress in their careers.

- Offer competitive benefits: Regularly rewarding employee contributions through bonuses or recognition programs will enhance the attractiveness of your organization.

- Improve employee engagement: creating and maintaining a positive, inclusive work culture is achieved by encouraging open communication, soliciting employee opinions and involving them in decision-making processes.

Sourcing Strategies: Sustainability First

88% plan to invest in sustainable development initiatives

With 88% of companies planning to make sustainable development investment efforts, there is growing recognition of corporate environmental and social responsibility over the long term.

In addition to the directives implemented by the European Union concerning corporate obligations in terms of sustainable development, France has adopted a duty of vigilance law since 2017. This legislation aims to make large companies accountable for respecting human rights and the environment throughout their global supply chains. Sustainability is becoming increasingly important for companies because of their impact on the environment, the social responsibility they entail, the legal compliance required and consumers’ growing expectations of transparency and ethics.

Group purchasing can help companies improve their procurement strategy in several ways.

Negotiating better prices: group purchasing allows several companies to pool their purchasing volume, enabling them to negotiate better prices with suppliers due to their greater purchasing power.

Cost reduction: group purchasing enables companies to reduce their overall procurement costs. This involves not only savings on product prices, but also a reduction in order processing and inventory management costs.

Supplier management: group purchasing often helps companies to identify and select suppliers. It enables suppliers’ capabilities, reliability and compliance with regulatory requirements to be assessed, thereby reducing procurement risks.

34% of those surveyed have used a group purchasing organization (15% for more than a year and 19% for less than a year). 32% have not joined such a program but plan to do so shortly.

Nearshoring as a solution for stability and sustainability?

Companies recognize the importance of proximity and localization in their supply chain strategies. 53% of respondents stated that a majority of their suppliers are located close to or within their country.

Against a backdrop of geopolitical uncertainties, 30% of respondents say their company plans to start using local or geographically close suppliers. 48% plan to maintain momentum and continue these same efforts, reflecting a concerted effort to improve supply chain robustness.

Over the past six months, companies have been faced with supply problems, notably related to delays (54% of respondents) or product unavailability (41%). Therefore, companies are increasingly turning to a strategy of nearshoring. This allows business activity to be relocated to a country geographically close to its consumer markets. It also facilitates exchanges with suppliers and promotes better quality and compliance management.

The adoption of localized sourcing is in line with broader trends in sustainability and responsible supply chain management.

Choosing the right supply chain technology

When asked what supply chain challenges they had encountered over the past six months, 25% of companies surveyed said they had encountered technology-related difficulties. This is where supply chain management software comes into its own, enabling companies to optimize their operations and remain competitive. Investing in technology while ensuring workforce stability and adopting a sustainable approach is essential to meeting current and future supply management challenges.