DirectIndustry attended the Global Industrie exhibition in Paris this week and found 6 new autonomous mobile robots (AMRs).

Hicham Dhouibi contributed to this report.

Autonomous mobile robots, or AMRs, are transforming the industry by offering flexible and intelligent solutions tailored to various industries’ specific needs, particularly in logistics.

Used in warehouses, in various sectors including energy, electricity, and the automotive industry, AMRs can move freely in a work environment while avoiding obstacles. They can understand their operational environment, enabling them to navigate safely around obstacles and operate in the presence of human operators.

AMR vs AGV

Unlike automated guided vehicles (AGVs), which require specific guided paths, AMRs use data from cameras, laser scanners, and other sensors to navigate and make decisions.

We had the opportunity to meet Matt Rendall, the CEO of Clearpath Robotics, which manufactures AMRs under the Otto Motors brand (recently acquired by Rockwell Automation). During a press briefing, he summarized the difference between the two technologies.

“The way that I like to think about a busy factory is it’s an indoor city and you need different modes of transportation for a city to function. An AGV behaves on a fixed track like a train or a subway. And you need a train and a subway for a busy city to function properly. But you also need taxicabs.”

Taxis are the AMRs. And the ongoing labor shortage is particularly one of the key factors driving AMR adoption today. And market growth figures speak volumes.

AMR, a Booming Market

According to Mordor Intelligence, the Robotics Market size is estimated at USD 45.85 billion in 2024. It could reach USD 95.93 billion by 2029, growing at a CAGR of 15.91% during the forecast period (2024-2029).

The Mobile Robots Market size is estimated at USD 6.99 billion in 2024 and is expected to reach USD 23.56 billion by 2029.

AMRs are on the rise. They were highly featured at the Global Industrie trade show this week in Paris Villepinte. DirectIndustry uncovered 6 of them. Here is our selection, along with their main features and available prices.

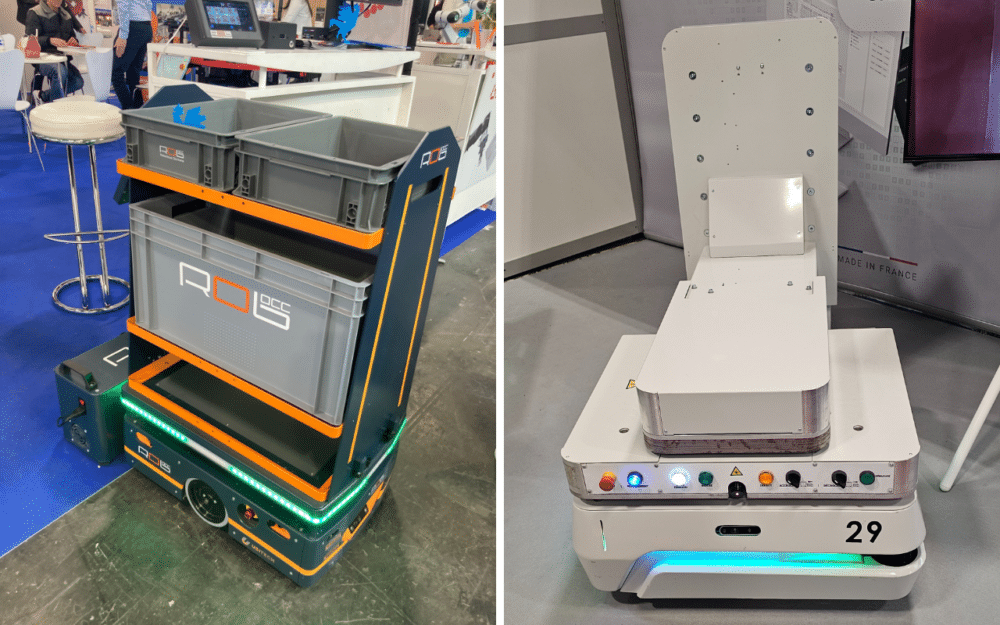

1/ Rob’Occ

Founded in June 2023 in France by 8 former colleagues, Rob’Occ offers a base of AMRs designed and manufactured in the French Tarn region, with 84% of the components sourced in Europe. This mobile base can be sold to integrators so they can develop customized solutions for their clients. However, Rob’Occ has also developed Roc-E, an AMR equipped with this mobile base and a shelf top capable of carrying crates. It can carry both commercial products and industrial tools or raw materials. Roc-E has a capacity of 100 to 150 kilograms.

New at Global Industrie

Roc-E is the AMR that the company presented at Global Industrie. The robot was able to navigate through the aisles of the trade show, amidst many people, without ever touching anyone.

This bi-directional robot is capable of operating for a full day of production, or even two shifts without any issues. With battery autonomy in full navigation, it can operate for about ten hours.

According to Lucie Bouscarat from Communication,

“There are several functions: you can call it with call buttons placed on stations. If someone needs to send a tool for repair, he can put it in, send it to the repair workshop, and then Roc-E leaves. When it arrives, it signals that it’s here. The person takes what they need from it and sends it to another station via the Roc-E screen or releases it. And if Roc-E has nothing to do, it will go and charge itself in its charging area on a dock.”

Deployment

Roc-E can be used in all types of companies: small, medium, and large. Its particularity is that it can be deployed easily in less than an hour on a large site. It does not require any investment, especially in terms of Wi-Fi infrastructure, explains Lucie:

“We first need to take it for a walk, it will do its rounds, look at everything around it, and make a map thanks to its geolocation sensors and cameras. It can map an area of 8000 m² in forty-five minutes. The map then appears on a fleet manager developed by our teams, accessible from a tablet fixed on Roc-E. We will then add in the app the red zones where Roc-E is not allowed to go, and the points of interest where it will need to go. Like all AMRs designed to work among operators, for the part of protecting people and dynamic obstacles, it will use cameras, ultrasonics, and lidar.”

Special Feature

Roc-E has its own Wi-Fi, so it does not communicate with the outside world. It does not need to be connected to a company’s Wi-Fi. The company says it is cyber-secure. The company also claims that the deployment is quick: no need to change the infrastructure or to stop production to deploy it.

According to Brice Renaudeau, a Ph.D. in robotics and one of the 8 co-founders of Rob-Occ,

“The vehicle chooses its route based on the technology embedded in the vehicle. So there’s no need to install a server. This is also what makes Roc-E different from all the AMRs you’ve seen. It knows the map, and then its methods of calculation, artificial intelligence that can help it make the best decision.”

The off-grid fleet manager allows prioritization. For example, if maintenance calls, it needs to go there first. It is possible to retrieve data, see how many flows the robot has made, in how much time, and the points where it is frequently called.

“As a result, we can optimize, and know if more AMRs are needed in that area, and fewer in another area because it has been less frequently called. The advantage is that, for example, the shelf-top module, which simply attaches, can be used during the day to bring things. And then at the end of the day, another top can be clipped and the AMR is used to collect waste or chips from an industrial machine.”

Price

The vehicle costs €35,000, and the recharge station costs €2,000. One station can serve multiple robots, and multiple stations can be set up for one robot to be placed at different locations within a factory. The complete solution is priced below €50,000.

2/ KUKA

KUKA has been manufacturing AMRs since the 2000s. However, until now, they have been focused on very heavy loads, up to 50 tonnes, mainly for the aerospace and space sectors.

Today, facing the growing demand from the general industry and the needs of companies involved in transit and pallet flow logistics, such as a European pallet in a truck weighing 1,500 kilograms, they have decided to launch a product specifically dedicated to this scope.

KUKA presents the KMP 1500P: “P” for professionals and 1500 for 1500 kilograms. Next month, they will release the 300-kilogram version. And by the end of the year, the 600-kilogram version will be available.

Composition

The KMP 1500P is equipped with two central drive wheels, allowing for very compact AMRs to pick up pallets near loading docks on conveyors or other equipment. The AMR can dock at loading docks or conveyor loading docks to retrieve pallets.

A lifting system allows for the top loading of cargo. A roller conveyor system can also be installed and connected to an automation system for automated operations within the environment.

According to Guillaume Masson, project manager at KUKA, the AMR is completely autonomous.

“The goal is to make it autonomous so that the investing company can free up its forklift operator for other tasks and completely automate that area without needing to add additional personnel to increase factory production flow and capacity.”

The AMR also contains Sick sensors that provide information. It also features industrial cameras from the market, on which KUKA has developed algorithms to detect humans and obstacles in the environment. An AI-powered software retrieves data (such as stock levels, shelf, or AMR locations) and manages navigation in the environment.

Special Features

According to Guillaume Masson,

“Today, in the market, the platform design is quite common among different producers. Today, all customers want to achieve ROI as quickly as possible. So the manufacturer that markets the product will focus on the price. This means that all platforms are starting to look alike, meaning they have the same design and manufacturing to achieve the lowest possible production cost. What really sets one manufacturer apart from another is the software and interfacing they provide, having a very intuitive navigation software that is versatile and scalable over time. This means that the end customer, who has designed their production line and cost for three years, doesn’t want to change everything when they add a new machine. They want to expand without redesigning everything.”

Price

A fully-optioned 1500-kilogram model with charger, cameras, and QR code will be around €48,000 to €50,000.

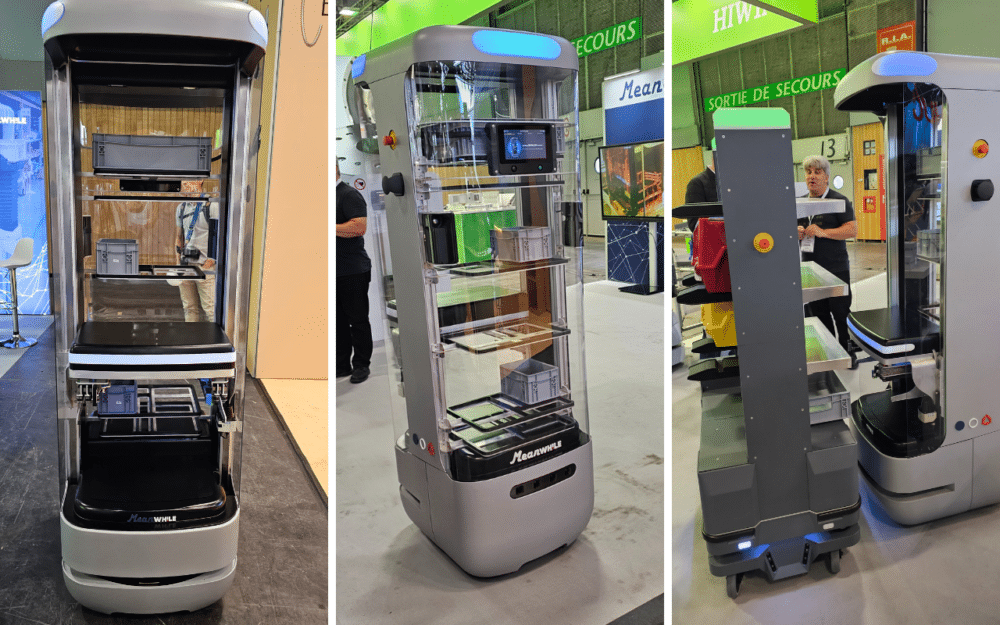

3/ Meanwhile

Meanwhile is a French company based in Lyon and founded in 2018. They design autonomous mobile robots with natural navigation based on mobile bases designed by other manufacturers, such as Omron.

Initially, the company targeted the medical field, aiming to create robots for hospitals to assist and relieve staff, allowing them to better care for patients while the robot navigates hospitals, delivering and unloading medications.

Today, the company is also targeting the industrial sector, with autonomous mobile robots with automatic loading and unloading.

New at Global Industrie

At Global Industrie, they launched the XuP Stacker, paying tribute to Saint Exupéry, a philosopher and technologist from the Rhône-Alpes region where they are based. The XuP Stacker will primarily target micro-precision companies, electronics, and watchmaking.

According to Sacha Stojanovic, CEO,

“It is an autonomous mobile robot with natural navigation that can access any workstation, including desks, workbenches ranging from 43 cm to 1.55 m in height, Euro norm bins, and other types of products like back which are between 20 by 30 centimeters, up to 30, 40 centimeters wide.”

The robot can retrieve its bins and store them in its backpack cabinet. The AMR recognizes the bins and where they are positioned. It can adjust its position and bin grip, even if the bin is slightly offset. It can store the bins in the backpack cabinet and can deliver the bins either individually or to different locations.

The robot also has arms. It can approach another robot, enter into communication with that robot, and either pick up or place a bin on it. There is identification of where the bin is positioned so that it can correct its position and adjust its arms relative to the bin’s position. Then it can simply pick up the bin, store it in its cabinet, and then deliver it elsewhere.

Price

The company did not disclose their prices for competitive reasons. They were however able to tell us that for a robot on a lease system, you’re looking at a monthly budget of around 2500 euros.

4/ e-cobot

The company e-cobot, founded in 2016 and based in France (Nantes), offers a range of mobile AMR robots called Husky. These robots, made in France, are capable of carrying loads for various industries including aerospace, logistics, and manufacturing.

Their robots are equipped with two types of artificial intelligence: onboard intelligence within the robot, enabling local decision-making based on various sensors to navigate efficiently, and intelligence within the MyCobot software suite, which manages the fleet of robots, mission orders, mission priorities, and scheduling. The MyCobot suite is compatible with multiple robots and brands.

New at Global Industrie

Their product, the Husky Transpat, whose new generation is showcased at Global Industrie, is designed for pallet transport, managing pallets from unloading the truck to storage areas, or even assisting in shipment preparation.

Special Feature

According to Clément Laurence, head of R&D, whom we interviewed,

“What sets us apart is that we control the entire value chain. We are both the manufacturer and the designer, conceiving and manufacturing our robots and installing them. In addition, we develop the entire software suite, MyCobot, making us completely autonomous in our product design. We are not dependent on anyone. This gives us a significant advantage, as we control the AI algorithms, navigation algorithms, and hardware, providing us with a deeper understanding of our industry.”

Price

The company did not provide us with a specific price for the solution, preferring to focus on flow optimization.

“We primarily offer flow consulting and auditing, so talking about a price doesn’t make sense. It’s more about flow optimization. We start with an auditing mission where we advise clients on which flows to optimize, and then we propose solutions based on this audit, providing them with a comprehensive installation of both products and software.”

5/ Jnov

Jnov introduced two types of highly compact mobile robots two years ago, capable of lifting very heavy loads ranging from one ton to forty tons.

Their purpose is to handle heavy loads for both movement and docking, meaning they can precisely move large, heavy equipment.

Special Feature

Several of these small robots can position themselves at the four corners of a large load, enabling them to lift, transfer, and move it as if it had wheels. There are no limitations based on the size of the product to be handled. Thus, it’s possible to handle products ranging from one to two meters in length to as long as fifteen or twenty meters, providing great flexibility.

According to Rémy Colas, CEO,

“The advantage of being small is that it’s much easier to integrate. We can incorporate it into many more systems, taking up minimal space on the ground. When moving with robots, we move within the footprint of the product being transported, without losing any volume. So that’s a significant advantage.”

Target Audience

Jnov’s robots are intended for the manufacturing industry. Manufacturers in aerospace use these robots for loads up to 4 tons. In the energy sector, can transport very heavy loads, often exceeding thirty tons.

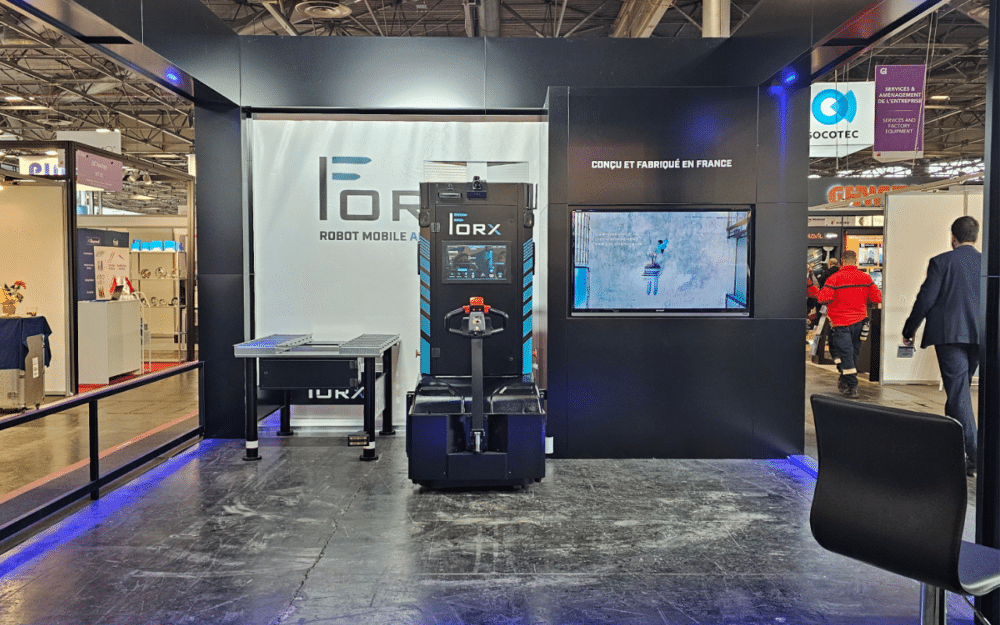

6/ FORX

FORX offers a mobile stacker for rental rather than sale, designed and manufactured in France.

Special Feature

According to Mélanie Cazars, Marketing Manager,

“The goal is to offer cutting-edge technology accessible to all. We are an industrial manufacturer at the core and realized that accessing AMR technology was quite challenging for smaller companies. Only large corporations could afford it due to prices starting from eighty to one hundred fifty thousand euros, requiring significant liquidity. So, we decided to democratize autonomous mobile robots for pallet handling and offer the possibility for small to medium-sized enterprises to afford this system.”

Price

FORX offers a mobile stacker starting from 1400 euros per month for a minimum of forty-eight months. The package includes maintenance, biannual inspections, software updates, and replacement of defective parts.

At the end of 48 months, the client can either renew the contract or decide to stop. If the client renews the contract and there have been technological updates to the robot due to new standards or improved components like sensors or more efficient lidars, the client returns the old stacker and receives a technologically updated machine.

Deployment

During setup, users move the autonomous mobile robot around the building using the handle, mapping the environment with its lidar. Once the mapping is complete, the client defines their flows and the areas where they want the AMR to move. Based on the environment and defined flow zones, the AMR chooses the best path. If there are multiple AMRs in the logistics warehouse, the integrated software intelligently determines which robot is closest to a specific drop-off or pickup point and sends the appropriate request.

Commercialization

Commercialization begins in June 2024, with initial clients primarily in the logistics and agri-food sectors.