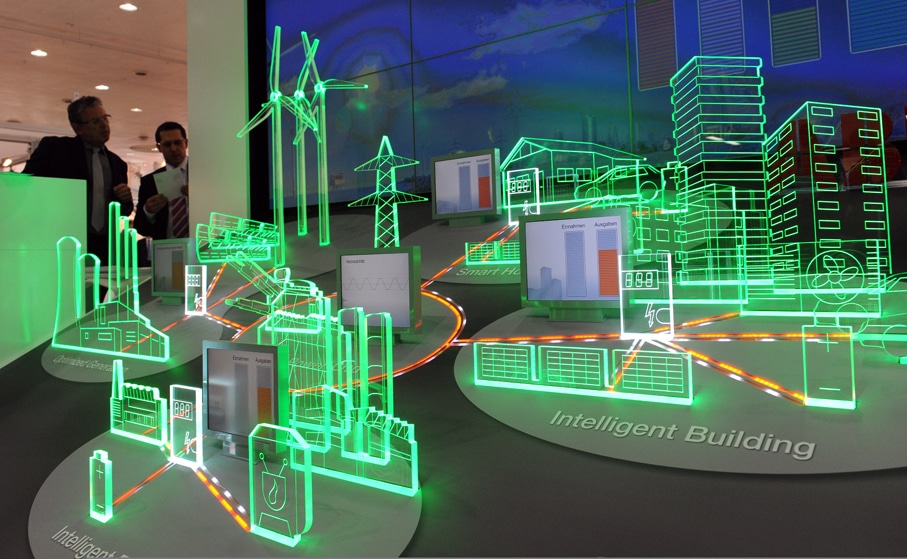

Energy management is a major theme at this year’s Hannover Messe, as new technologies are poised to provide cleaner and cheaper electric power. Here’s an overview of the latest initiatives favoring transition to sustainable energy in tomorrow’s factories.

Automaker Tesla says its high-performance electric cars are set to transform driving. So, it’s no surprise that its new lithium battery facility in Nevada will do the same for factories. It will rely on a 70 MW photovoltaic solar roof and a nearby wind farm in a bid to run without drawing power from the grid.

The company says its new manufacturing plant is expected to reduce the kilowatt-hour cost of its battery packs by more than 30%. This is part of Tesla’s mission to “accelerate the world’s transition to sustainable energy.”

The Demand-Side Response Concept

While many industrial companies share these ambitions, few have the luxury of starting from a greenfield site making a new type of product. Aggregate Industries wants to improve its energy efficiency and reduce carbon emissions. But the building materials company must do so with existing assets rather than starting afresh. It has begun by establishing a detailed picture of its energy consumption, and using this information to generate revenue.

The concept is called demand-side response. Energy companies are prepared to pay businesses to reduce their consumption during periods of high demand because this avoids firing up additional facilities or buying energy on the open market. Aggregate Industries installed connected performance and control sensors on 255 asphalt tanks in 40 plants in the UK. The company works with technology firm Open Energi to analyze and act on the data.

Donna Hunt, Aggregate’s head of sustainability, explains:

Bitumen tanks, if well insulated, will maintain their temperature even if the heat source is turned off. We set the parameters with Open Energi to ensure our processes and quality would not be affected, but we are able to turn off some of the tanks at predicted periods of high demand on the grid. If you are prepared to be flexible, you can generate good returns.

The average duration of a switch is less than 5 minutes, reducing its impact to nearly nothing, according to Hunt. Yet the process has helped the firm deliver around 3.6 MW of flexible demand to the grid and save 40,000 tons of CO2 emissions over 5 years.

It also offers a competitive advantage, as Aggregate customers are increasingly concerned about carbon emissions and aim to limit the so-called “embedded carbon” in concrete and other aggregates.

The process helps save our own energy and CO2 and supports the wider needs of the industry.

Saving Energy with Data

Software company Wonderware and service firm Peak42 helped drinks company Lucozade Ribena Suntory (LRS) install individual metering systems that convert raw energy data into actionable information. Online dashboards also raise awareness of energy consumption and promote behavioral change.

Gary Burford, energy and sustainability manager at LRS explains:

We need to understand where we are using energy across the site and improve the visibility and accessibility of that information to allow us to make changes. The graphical interfaces and real-time data offered by the Wonderware solutions will engage our people, giving them an immediate awareness of their impact on energy usage and empowering them to make the small changes that can, over time, deliver big results.

An Impossible Challenge?

Industrial firms are anxious to reduce emissions and their energy bills, says Bruce McLeish, vice president, energy supply and risk management at consultants Ameresco. However, those hoping that simply monitoring, collecting and analyzing data and disseminating conclusions will lower consumption may be disappointed.

For Bruce McLeish,

There are a lot of technologies offered in this space. Many offer real-time insight and analytics and offer the potential to save energy. They can identify equipment that is not running efficiently or need not be running at all. They can find errors in heating and ventilation systems.

But reducing energy consumption with these technologies requires a commitment throughout the management hierarchy.

The biggest problem is that manufacturing can be so lean, in terms of personnel, that when the systems and goals are introduced they don’t have time to find the real benefits.

At the same time, he says that companies are treading the same path as Tesla by looking to generate power on site, largely through photovoltaics.

We recommend companies look into it. It can provide an effective, long-term hedge against fluctuating prices you cannot get elsewhere, if it is installed behind the meter.

Any industrial energy strategy will have to deal with the uncertainty of pricing and legislation governing carbon emissions. Taking measures to reduce consumption and produce their own energy can help them regain some control.