What if engineers could predict when maintenance should be performed on machinery and equipment? Modeling data collected by new sensors inside machines and engines now enable predictive maintenance (PdM). The end-game is maximum efficiency and the complete automation of business decisions.

First Steps: Data Monitoring

PdM is designed to avoid unplanned downtime and accidents, reduce unseen damage, wear, engine failure and emergency repairs, and make parts replacement merely a matter of scheduling. At its core, PdM systems can be very simple, says Mobeen Khan from AT&T’s Industrial IoT Solutions Dept. The service has deployed PdM systems in the heavy equipment industry. “It’s very simple to know an alarm is being generated, or the check engine light in a tractor is on. You can then manually dispatch someone to go fix something.”

The next step is to monitor streams of data to see if something is about to break, increasing the uptime of assets. “Say there was a downtime of two days every two years. We can get that down to a few hours.”

Maintenance on Demand

A great example of PdM at work is in the logistics industry. Supported by the EU, the Maintenance On Demand (MoDe) project involves 11 companies—including Volvo and DHL—pooling their technical know-how to develop a commercially viable truck that autonomously signals when and how it requires maintenance.

Sensors are placed in the engine’s injection, damper and oil systems to detect damage or degradation. They send updates over a wireless network to a maintenance platform, which uses this condition monitoring data to make maintenance decisions.

Since all the trucks are centrally monitored, fleet management software can re-route them to maintenance depots. Proponents of the MoDe project claim that uptime is increased by as much as 30%.

PdM Means Less Maintenance

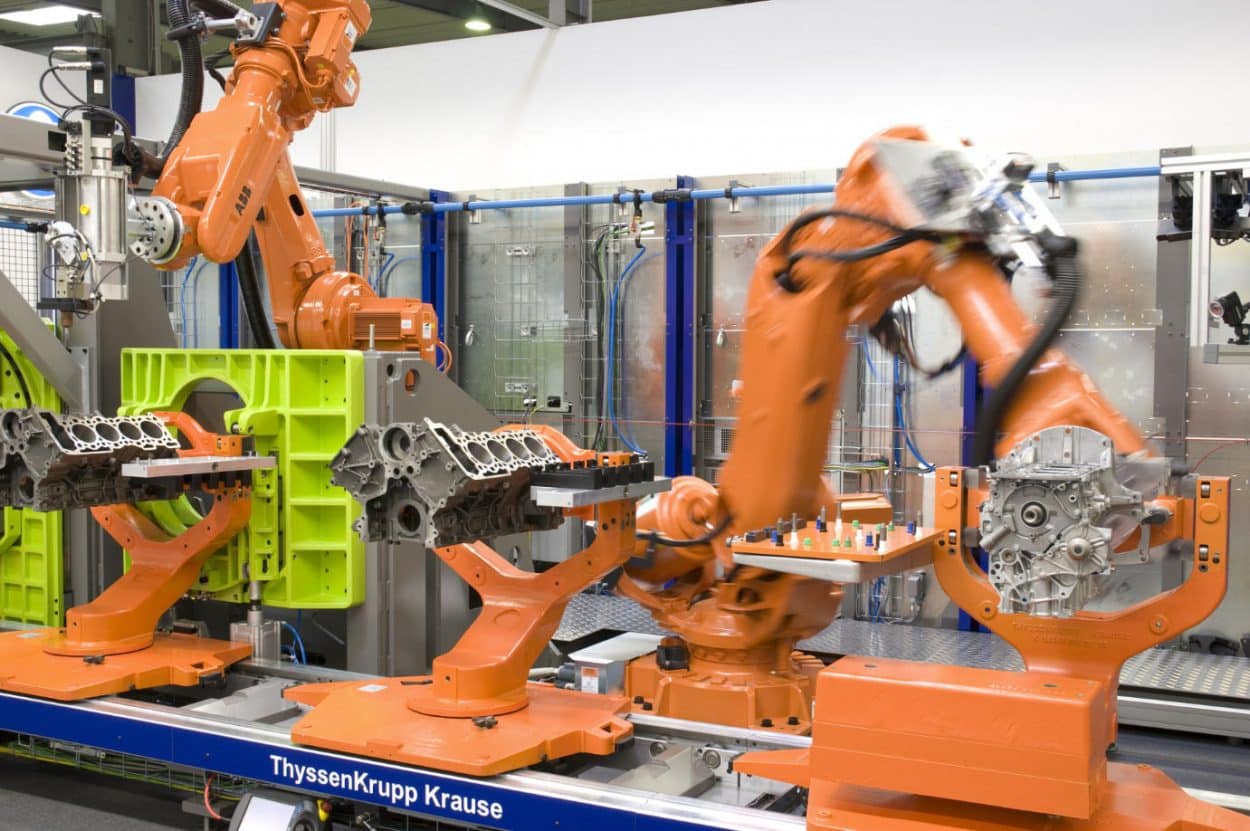

What PdM brings is real-time feedback. Patrick Bass, CEO at Thyssenkrupp North America at London’s IoT Expo in February 2016, explains:

We’ve already seen through our pilot phase of analytics that in three to six months we can increase uptime of assets by 50%, which is huge and has significant customer value as well as efficiency value.

But it’s not just about maximizing uptime; another advantage of PdM is that it allows a company to visualize and operate their machinery in a much wider business context. “Now you can look at equipment uptime in the context of downstream processes, such as spare parts supply, because you have more intelligence about what you need, and when you need it.”

This is what’s so radically different from the past.

We knew when something would fail because we tested it. But with predictive analytics you find that the unit doesn’t break because a component wears out, but because of the effect of a lot of other factors in the system.

In short, using PdM can mean machinery needs less maintenance.

Predictive Analytics

Behind the trend toward PdM is a new thirst for predictive analytics throughout industry, which is set to become a standard safeguard for business. For now, retail is blazing the trail, accoridng to Professor Michael Feindt, ex-CERN scientist and both founder and chief scientific advisor at Blue Yonder. The compnay makes predictive software for retailers, including German online retailer Otto.

What we want to do is automate decision-making. Retail has very tiny margins, so there is pressure to make all the processes efficient.

For retailers, predictive analytics is all about wasting less food, fewer out-of-stock situations, and internet-style real-time pricing.

By knowing the probability sales curve of a product, you can not only make sure you don’t get out of stock situations, but you can prioritize net profit, revenue, or even share price. Strategic goals can be broken down to each single decision made in every store in a supermarket chain.

The true power of data science and algorithms is only now becoming obvious to industry, not only as a way to optimize core processes, but to become a new kind of business, moving from a reactive to a predictive business where data is no longer wasted and complex business decisions are automated.