Founded in 2007, EDITAG manufactures turnkey IIoT solutions for the logistics sector, combining RFID technology and connected sensors. While the French company’s market focus has always been on the supply chain, they were first involved in another sector: the art market.

EDITAG (Electronic Data Interchange Tag) develops IIoT solutions that facilitate logistics applications thanks to their patented technology. The hybrid system is called mOOnTAG (for modular online / offline tag), and it enables the monitoring and optimization of order preparation processes and logistics flows using RFID sensors (offline tag) as well as IoT sensors (online tag).

For Frédéric Pithoud, EDITAG’s CEO,

“Project managers often ask themselves whether they should use passive (RFID) or active (sensors) technologies. We think we need both technologies, but not at the same time. The mOOntag system involves a passive mOOntag ID and an active mOOntag sensor and makes it possible to benefit from both worlds in a modular way. For example, when you have an empty bin, you don’t need to geolocate and monitor it so a simple passive tag on it is enough. This allows you to reduce the number of active sensors deployed on a site.”

Online & Offline Tags

Location system (Credit: EDITAG)

Each mOOnTAG pack involves modules that are adapted to a specific business application. It can, for example, be deployed to enable the tracking of manufacturing assets in real-time therefore optimizing intralogistics flows and for replenishment orders. In this industrial process, replenishment orders are sent when the replenishment cart reaches the penultimate stage of production. Until now, an operator had to check the presence of the right cart at this stage and enter the order in the information system. With the mOOnTAG, this task becomes automatic. When the cart, equipped with a mOOnTAG, enters the penultimate stage of production, it is automatically detected and the mOOnTAG triggers the replenishment request in the system. It is the detection of localization that activates the order.

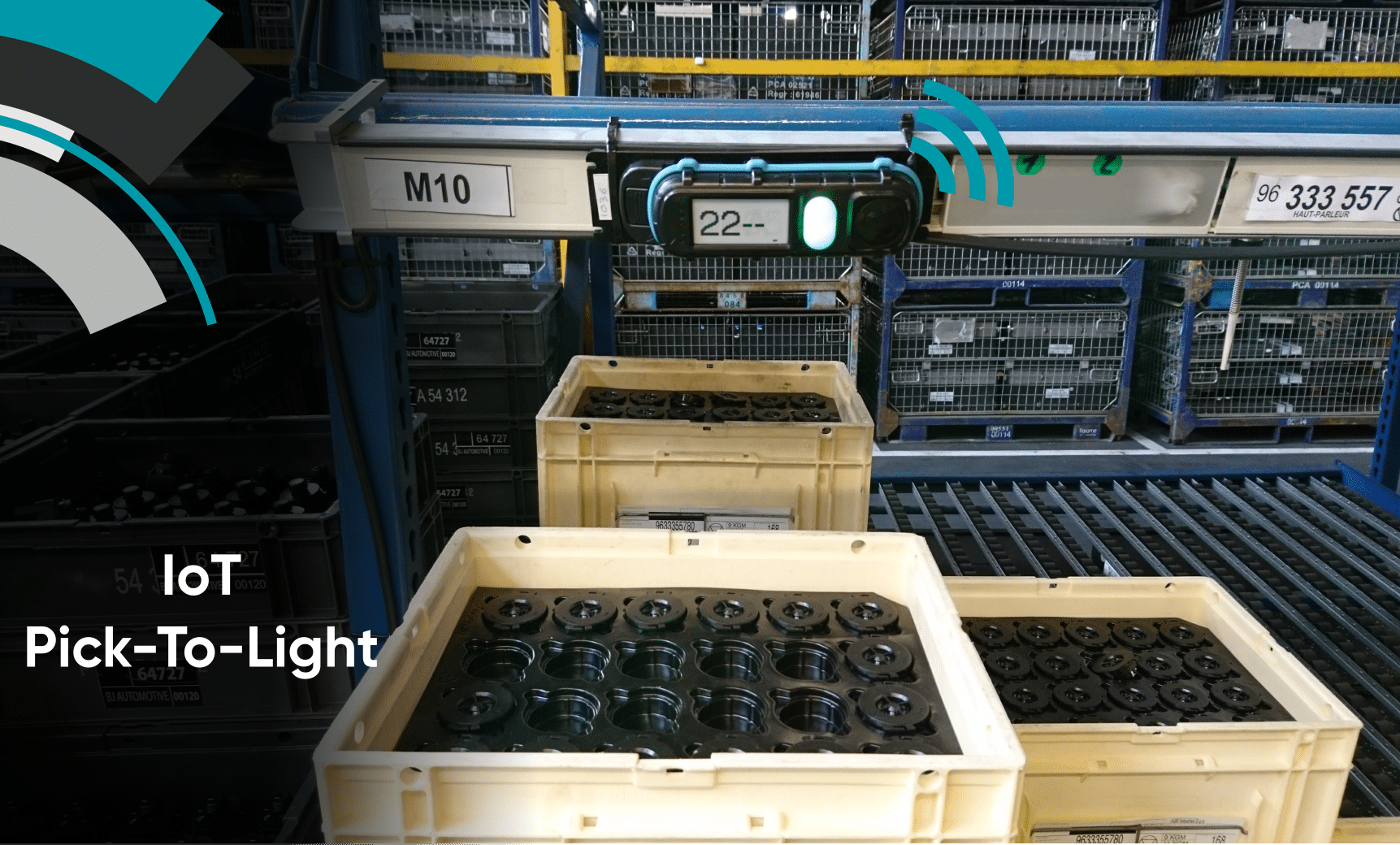

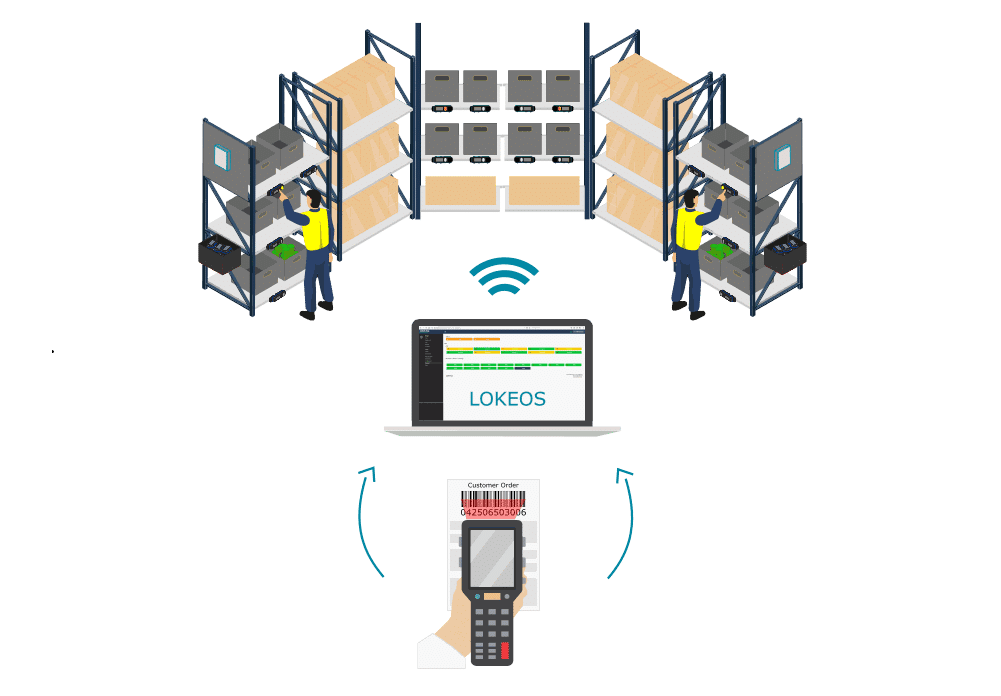

mOOnTAGs can also be used for order picking and kitting. For preparing component kits, for example, the bins equipped with a mOOnTAG and pick-to-light IoT sensors light up and immediately guide the operator towards the right bin to take the parts to. A screen module also displays the quantity of parts to be taken. The sensors detect the movement of the hand and once the part is picked by the operator, they automatically update the stock in the supervision system, LOKEOS, without the operator having to indicate anything.

“The idea is to avoid manual data entry and digitize business processes while keeping the operator at the center of these processes. Our solutions are designed to bring connectivity and intelligence to the heart of human operations. This increases human productivity and reduces the time spent looking for things. It allows us to reduce errors in the preparation of parts kits which have a high cost if one part is missing and we need to find another one. And since our system enables data collection, we can also improve cycle times.”

The company says their pick-to-light system allows a gain of 30% productivity on dispatching processes.

Pick-to-light system (Credit: EDITAG)

Agnostic Technology

The mOOnTAGs can function on private company networks and communicate natively with LoRaWAN radio technology. EDITAG have also developed their own long-range radio technology.

“Our radio technology is very light. For example, there is no need to install radio repeaters every 20 meters in a factory.”

Their software controller LOKEOS is another advantage of the solution as it allows the system to be compatible with other vendors’ technology.

“We are agnostic. Our software controller can be interfaced with existing solutions such as IoT platforms developed by other editors or interfaced with ERP or with SAP. Our LOKEOS software controller acts as an all-in-one backbone system for data acquisition. It propagates data through a simple digital interface to all the business applications that need to be fed with field data.”

EDITAG Arts

If EDITAG’s market focus today remains the supply chain, the company was at the beginning involved in a niche market: art.

“In the mid-2000s, we started talking about RFID chips, which is now one of the technologies in the IoT perimeter. But at that time, we were only talking about RFID for large volumes in large groups. Our idea was to develop solutions accessible to smaller players for logistics and supply chain applications. So we developed a technology with embedded intelligence and information collected by means of RFID readers and tags. But in 2007, the market was not yet ready for the supply chain. So in the meantime, we moved into a niche market, artwork monitoring: EDITAG Arts.”

They applied their technology to the conservation of artwork in museums (involving humidity and temperature sensors), for inventory, for traceability and for monitoring collections in storage.

“A few years later, when we started talking about industry 4.0, we naturally turned to logistics and supply chain applications with the patented multi-standard technology we had developed in the meantime: mOOnTAG.”

Smaller Organizations

mOOnTAGs are now used in various industrial sectors such as the automotive and manufacturing industries in France and elsewhere in Europe, with clear ambitions for the United States. EDITAG’s main and original target is also to be accessible to small and medium-sized enterprises and contribute to the digitization of French industry in this way.

“In France, the challenges of digitization are at the level of SMEs. Digitizing French industry means digitizing SMEs. So we have designed our solutions to be usable by SMEs too. But we also work with large groups.”

With the pandemic and the rise of e-commerce activities, the need to optimize logistics and order preparation processes has become crucial and could bring the company new markets. For the moment, EDITAG’s customers buy the solution, which includes the software, the hardware and associated services such as maintenance. The cost of deploying the technology depends on the size of the organization and the business applications. The company stated that they have deployments at €20,000 and others at €600,000, depending on the quantity of mOOTAGs used and on how many industrial sites. The company is also working on a subscription-based plan.

Following the COVID-19 pandemic, EDITAG’s technology could also be used to facilitate the reopening of public buildings such as museums. The EDITAG Arts solution includes an IoT sensor, the m3D PC detector, specifically designed to count visitors and trigger alarms with accuracy greater than 99%, according to the company.