At CES 2026, innovation is moving decisively from concept to deployment. Robotics, AI-driven mobility, advanced sensing and environmental engineering solutions demonstrated how digital technologies are now reshaping industrial operations, infrastructure and sustainability strategies. From robotics platforms to AI-driven mobility software and low-carbon soil remediation, CES 2026 once again proves that industrial innovation is accelerating well beyond consumer electronics.

CES Las Vegas, a Global Innovation Hub

Held every January in Las Vegas, CES (Consumer Electronics Show) is one of the world’s largest and most influential technology events.

The 2026 edition, which officially starts today January 6th until January 9th, is bringing together over 130,000 visitors, nearly 4,000 exhibitors, and thousands of startups from more than 150 countries.

This year’s key trends include:

- Artificial intelligence embedded at the edge

- Robotics and automation for real-world operations

- Software-defined vehicles and smart mobility

- Sustainable, low-carbon industrial technologies

Among the many announcements, four innovations stood out for their immediate relevance to industrial stakeholders.

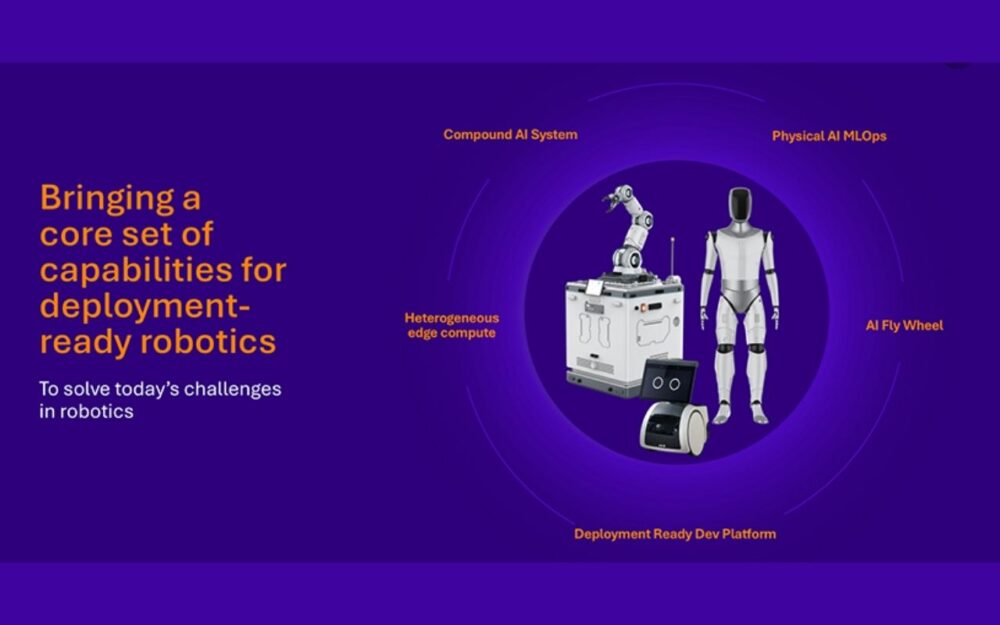

1/ Qualcomm: Powering Physical AI from Industrial AMRs to Full-Size Humanoids

The innovation

Qualcomm is unveiling a next-generation, full-stack robotics architecture designed to move Physical AI out of labs and into real-world industrial environments. Built on safety-grade, high-performance SoC platforms, this comprehensive approach combines hardware, software and compound AI to power general-purpose robots, from industrial AMRs to full-size humanoids capable of reasoning, adapting and making decisions.

At the core of this announcement is the launch of the Qualcomm Dragonwing™ IQ10 Series, the company’s latest premium-tier robotics processor, purpose-built for advanced autonomous mobile robots and humanoid platforms.

Qualcomm is building a broad ecosystem around its robotics platforms, working with partners such as Figure, KUKA Robotics, Advantech, Booster, VinMotion, Robotec.ai and VinMotion to bring deployment-ready robotics solutions at scale. Discussions are also underway with KUKA for next-generation robotics systems.

Key technology highlights

- Dragonwing™ IQ10 Series, delivering high-performance, energy-efficient “brain of the robot” capabilities

- Safety-grade, low-latency architecture optimized for industrial reliability and scalability

- Support for advanced perception, sensor fusion, motion planning and manipulation

- Native enablement of end-to-end AI models, including Vision-Language Models (VLMs) and Vision-Language-Action (VLA) architectures

- Mixed-criticality systems combining real-time control with high-level AI reasoning

- Integrated AI data flywheel to continuously collect, train and deploy new robotic skills

Why it matters for industry

For industrial players, Qualcomm’s approach addresses one of the biggest barriers to robotics adoption: the last mile between R&D and real operations. By offering a unified, scalable and energy-efficient robotics stack, Qualcomm enables manufacturers, logistics providers and integrators to deploy intelligent robots faster, with higher reliability and lower total cost of ownership—paving the way for humanoids and advanced AMRs to operate safely at industrial scale.

VinMotion’s Motion 2 humanoid, powered by the Qualcomm Dragonwing™IQ9 Series will be displayed at the Qualcomm Booth #5001 during CES.

2/ Intellias: AI Software as the Brain of Software-Defined Vehicles

The innovation

Intellias is showcasing a comprehensive vision for software-defined mobility, centered on AI-driven engineering and a chip-to-cloud Automotive Technology Platform designed to accelerate the transformation of vehicles into continuously evolving digital systems.

At the heart of the company’s presence is a live demonstration of IntelliKit, Intellias’ modular automotive platform built on a real vehicle E/E architecture. It illustrates how AI, cloud connectivity and flexible software stacks can be deployed in production-ready mobility solutions.

Read also our reports from CES 2025

Key technology highlights

- IntelliKit Automotive Technology Platform, enabling end-to-end chip-to-cloud engineering

- Real-vehicle E/E architecture supporting scalable, software-defined vehicle platforms

- Advanced in-vehicle infotainment (IVI) and high-quality 3D digital instrument clusters

- Seamless over-the-air (OTA) updates and cloud integration for continuous software evolution

- AI-enabled driving scenarios demonstrating real-time decision support and situational awareness

New capabilities unveiled at CES 2026

- Conversational GenAI Voice Assistant, powered by SoundHound AI, enabling natural, context-aware driver interactions

- Computer vision features using YOLO v12 for real-time object detection and tracking on QNX RTOS, combined with OpenCV integration on Android Automotive OS (AAOS)

- Integration of Rust-based components into AUTOSAR Classic via the Intellias ECU Kit, fully assessed for ASPICE CL2, functional safety and cybersecurity compliance

- A customizable digital ecosystem including an OEM App Store, Unreal Engine–based instrument clusters, OTA updates and integrated cybersecurity via VicOne

Beyond vehicle features, Intellias is also showcasing its AI-Enabled Engineering Maturity Model, a framework designed to help OEMs and Tier 1 suppliers adopt AI systematically across their engineering processes.

This structured approach provides organizations with a clear roadmap for scaling AI, improving engineering efficiency, product quality and time-to-market.

Why it matters for industry

For automotive OEMs, Tier 1 suppliers and mobility providers, Intellias delivers more than software components—it provides a production-ready blueprint for software-defined vehicles. By combining AI-driven engineering, chip-to-cloud platforms and ecosystem partnerships, Intellias helps industrial players reduce development complexity, ensure compliance and accelerate the shift toward intelligent, updateable and service-oriented mobility systems.

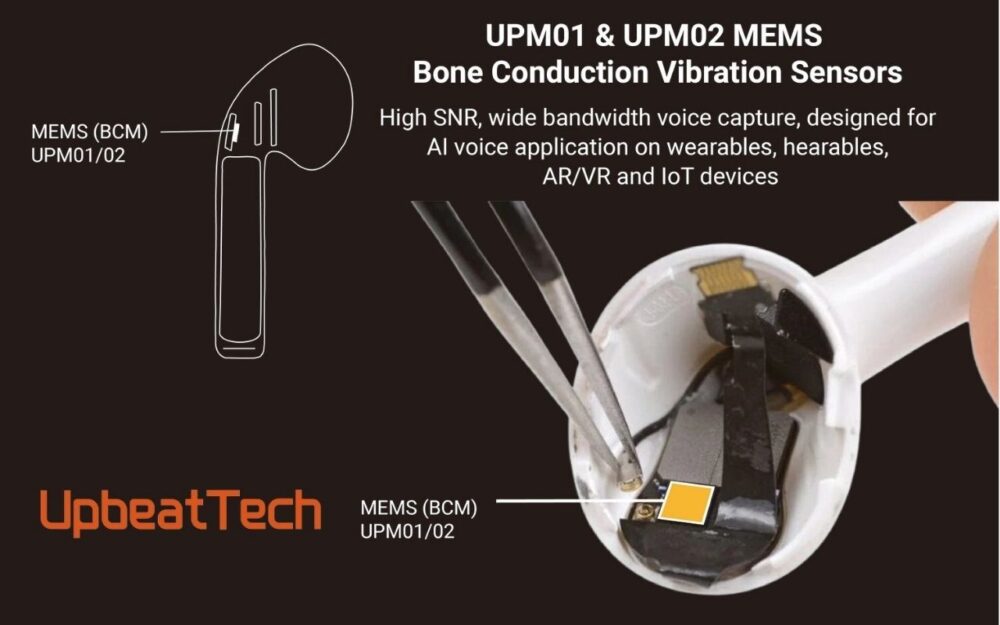

3/ Upbeat Technology: MEMS Redefined for AI-Driven Sensing

The innovation

Upbeat Technology unveils a new family of high-bandwidth MEMS vibration sensors, setting a new benchmark for AI-powered sensing in noisy, vibration-intensive environments. The UPM01 and UPM02 sensors are designed to overcome the limitations of conventional acoustic microphones by capturing mechanical vibrations directly, enabling more reliable voice, diagnostics and intelligent sensing.

This MEMS portfolio is engineered to work in synergy with Upbeat’s ultra-low-power edge AI MCUs, enabling always-on sensing with minimal energy consumption.

Key technology highlights

- UPM01 and UPM02 MEMS vibration sensors with a flat frequency response from 5 Hz to 12 kHz

- Signal-to-noise ratio (SNR) of up to 68 dB, enabling high-fidelity signal capture

- Combined analog and digital interfaces for flexible system integration

- Optimized for integration with Upbeat’s UP301 dual-core RISC-V AI MCU

- Ultra-low power design suitable for always-on, battery-powered devices

Vibration sensing for drones and robotics

In industrial drones, humanoid robots and autonomous systems, the UPM01 sensor detects ultra-low-level micro-vibrations associated with:

- Mechanical imbalance

- Component fatigue and wear

- Early-stage system degradation

This enables predictive maintenance, propeller health monitoring and automated diagnostics—key requirements for operational reliability, safety and equipment longevity in robotics and low-altitude autonomous systems. Notably, the UPM01 has already been in high-volume production throughout 2025, proving its readiness for real-world deployment.

AI voice and bone-conduction applications

For AI wearables such as smart glasses, earbuds and open-wear stereo headsets, the UPM02 sensor delivers exceptional voice isolation by capturing vibrations from the user’s voice while suppressing ambient noise. This enables:

- Clear voice calls in loud environments

- Reliable voice-command recognition for hands-free AI interfaces

- Whisper-mode input and discreet communication

- Extended battery life compared to multi-microphone acoustic arrays

These capabilities are critical for next-generation AR/VR devices and AI wearables, where voice clarity and energy efficiency directly impact user experience.

Why it matters for industry

For industrial manufacturers, robotics developers and IoT system integrators, Upbeat’s MEMS technology unlocks new sensing capabilities where traditional microphones and sensors fail. By combining vibration-based MEMS with edge AI processing, Upbeat enables:

- More reliable diagnostics and monitoring

- Reduced system complexity and power consumption

- Improved uptime through predictive maintenance

- Scalable sensing solutions from consumer devices to mission-critical autonomous systems

4/ MP GEOTEX: MP Cocoon®, A New Standard for In-Situ Soil Remediation

The innovation

French company MP GEOTEX is presenting MP Cocoon®, an advanced in-situ soil remediation system derived from its proven MP Remedia® geotextile technology. The solution is showcased on the Auvergne-Rhône-Alpes regional pavilion, highlighting French environmental engineering expertise on the global stage.

MP Cocoon® represents a hybrid geotechnical system capable of treating polluted soils directly on site.

Key technology highlights

- Functionalized geosynthetic encapsulation forming a secure treatment cell

- Combined biological and fungal remediation for biodegradable pollutants

- Selective sequestration of heavy metals and PFAS using biochars and technical media

- Integrated oxygenation network enabling continuous, reactivatable bioremediation

- No excavation, transport or centralized industrial treatment required

Why it matters for industry

MP Cocoon® addresses a critical global challenge: cleaning polluted land faster, cleaner and at scale, without disrupting projects or relocating contamination.

For construction, infrastructure and environmental engineering projects, MP Cocoon® delivers immediate operational benefits:

- Major reduction in logistics and soil transport costs

- Faster land reuse through simultaneous confinement and treatment

- Minimal carbon footprint thanks to fully in-situ processing

- Strong compliance with international regulations, including PFAS management

Industrial Innovation, Ready for Deployment

CES 2026 confirms a clear evolution: industrial technologies are no longer experimental. From AI-powered robotics and software-defined mobility to advanced sensing and low-carbon remediation, these innovations are designed for real-world constraints, regulations and operational efficiency.

For industrial players, CES is no longer about spotting distant trends—it’s about identifying deployable technologies that will define competitiveness in the years ahead.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)