When thinking of high-end tech products, Senningerberg in Luxembourg is not necessarily the first place that comes to mind. Yet 3D-scanner manufacturer Artec 3D has chosen to base both its headquarters and its production site there. Two years ago, the facility was further upgraded with a modern clean room that enables ISO 7-standard production. Our journalist, Kristina Müller, visited the site for an inside look. She spoke with CEO Artyom Yukhin about the specifications of Artec 3D’s scanners and the role of AI in their technology. They also discussed the company’s view of emerging smartphone-based competitors.

Wearing a white shirt, jeans, and sneakers, Artyom Yukhin, called Art by his colleagues and employees, looks very much like someone fresh from Silicon Valley. And rightly so, this is where he co-founded the company in 2007. Today, Artec 3D operates globally: its headquarters remain in Luxembourg, complemented by offices in California, Tokyo, Shanghai, Montenegro and Lisbon.

In its 18-year history, the company has contributed to numerous standout projects. One highlight: Barack Obama became the first U.S. president to have a 3D portrait captured using Artec 3D’s EVA scanner. The company was also involved in developing Apple’s face ID technology, which is based on their AI applied to 3D geometry interpretation.

Watch how Obama became the first U.S. president to have his 3D portrait captured using Artec 3D’s EVA scanner

Museums, Forensics, Aerospace: A Broad Customer Landscape

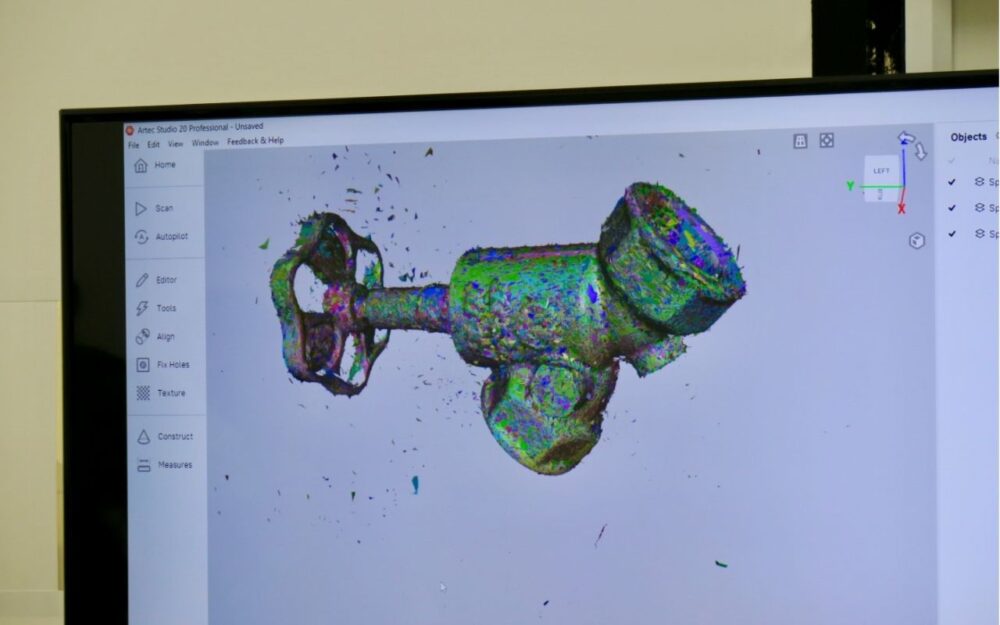

Artec 3D’s customer base spans a wide range of industries. In industrial design and manufacturing, the scanners support prototyping, quality inspection, and reverse engineering. Police, forensics, and military departments use 3D scanning to document objects and scenes objectively. For example this can be useful for freezing car crashes, accidents or crime scenes in time and enabling investigations that may last for years.

Other customers operate in automotive and aerospace sectors, healthcare and emergency services, sports and fashion, museums and cultural heritage, as well as gaming and film.

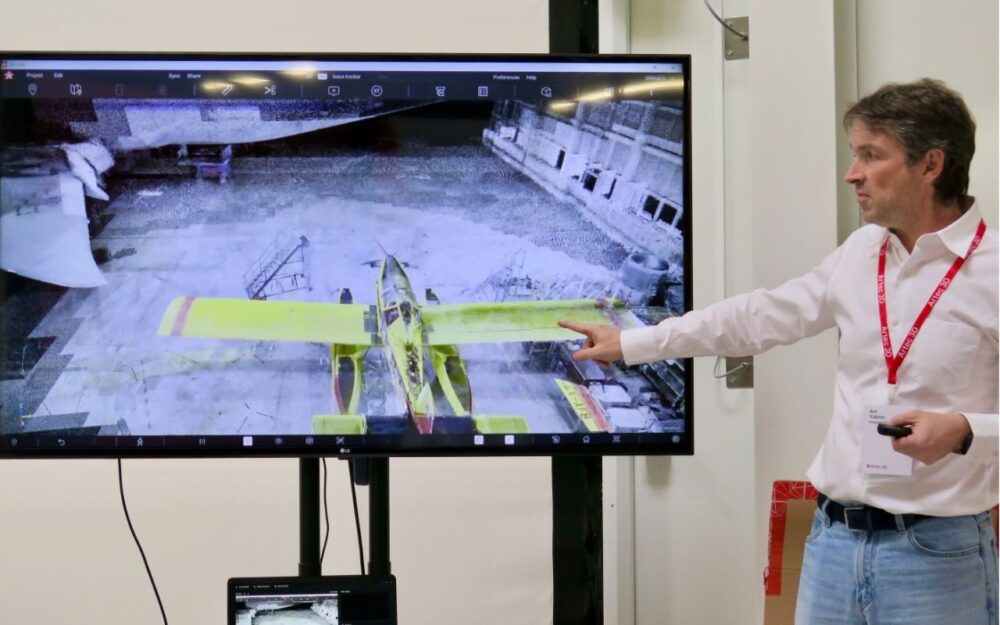

A fast-growing segment is construction. Reality capture for large installations is increasingly used to aid measurement, refabrication, quality control, and predictive maintenance. Artec 3D technology has been used, for example, to scan a Cargolux hangar and a Luxembourg Air Rescue helicopter.

Yukhin sees the strongest future growth in energy infrastructure, transportation, and defence.

Multisource Data Fusion and Targetless Scanning: Key Competitive Advantages

Artec 3D’s unique value proposition lies in combining different scanning technologies and merging the data into a single digital twin using AI-enhanced software.

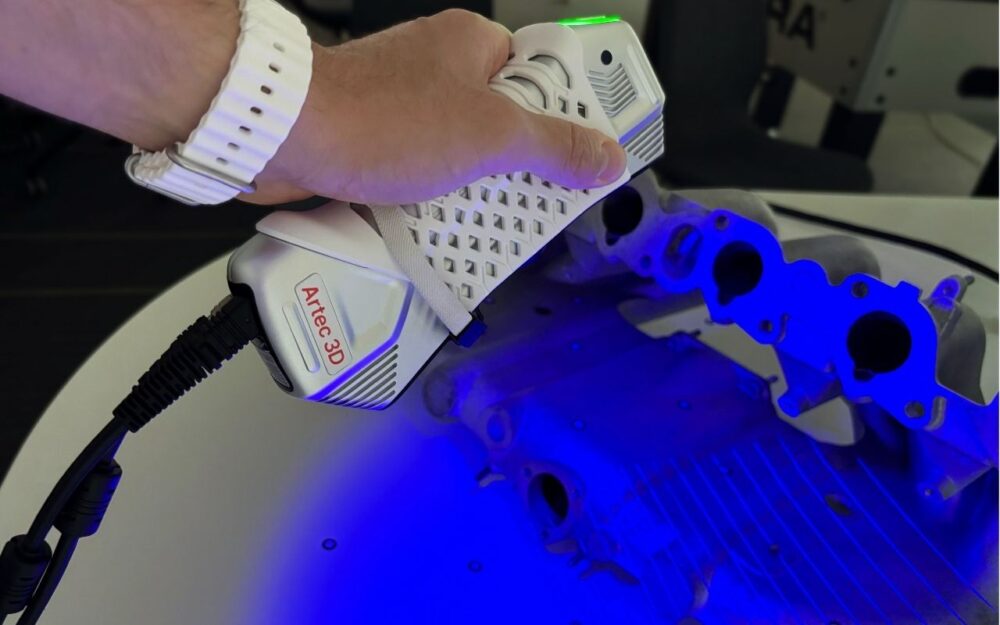

For long-range, high-precision scanning—up to 130 meters—the company offers the RAY II LiDAR scanner. It was co-developed and manufactured with Leica Geosystems in Switzerland. The data it collects is then merged with high-resolution close-range scans captured by the handheld LEO scanner. This scanner operates at one- to two-meter distances. AI algorithms align and fuse these sources into a unified model.

Other handheld scanners include the SPIDER. This one is for example used by police and archaeologists to capture ultra-high-resolution scans of complex objects in full color. A major advantage of Artec 3D’s handheld devices is their targetless scanning capability. This eliminates the time-consuming process of placing and removing reference stickers.

LEO, the company’s best-selling model, features an integrated touchscreen that provides immediate scanning feedback, explains Yukhin:

“A plumber, a nurse, a construction worker or a volunteer out in the field should be able to use it quickly.”

The color-coded display guides the user. Green indicates a correct distance to the surface. Red warns that adjustments are needed.

A Modern Clean Room for In-House Production

A significant portion of R&D takes place in Senningerberg, and the assembly of the scanners’ printed circuit boards (PCBs) is carried out in the clean room, inaugurated in 2023. The 300-square-meter facility can be accessed only through airlocks for staff and materials. Its ISO 7 certification enables tightly controlled conditions in temperature, humidity, air pressure and particulate levels. This ensures maximum precision and production safety.

Yukhin highlights why in-house production is essential

“We design things, so we want to have them in our hands to understand everything. It allows us to iterate very fast. Outsourcing would mean losing control. We are very proud of what we can produce ourselves.”

The clean-room production line follows a fully automated surface-mount technology (SMT) process. Multi-layer boards move through robotic stations where electronic components are placed, mounted, inspected and finally soldered in an oven with controlled temperature profiles. After final inspection, the boards are stored under specific conditions.

Accelerating Innovation: Support From the European Investment Bank

Artec 3D’s innovations constantly focus on AI implications and algorithms that enable even more advanced scanning technology. One example is the EVA scanner—on the market for over a decade—which received a fully AI-based upgrade called HD Mode. Using the same raw data, the algorithm more than doubled both resolution and signal-to-noise ratio.

More recently, AI photogrammetry has been integrated into Artec’s software, enabling objects to be extracted from video and combined with other scans. This multisource data fusion is one of the company’s most significant recent breakthroughs.

To support its long-term innovation pipeline, a venture debt loan secured from the European Investment Bank (EIB) makes Yukhin optimistic about staying ahead and further accelerating RDI (Research, Development and Investment). In June 2025, the EIB and Artec 3D entered a long-term partnership involving €15 million in venture debt from the bank. It is intended to support new product and software development activities of the EU-based company.

“This financing is essential when you do deep tech,” Yukhin says. “We have to compete with Chinese companies and currently feel the pressure from competitors who receive an infinitive amount of government injections and are catching up fast. This is why we are very happy to receive this acknowledgement.”

Smartphone Solutions Enter the Market

A new wave of competitors is emerging with smartphone-based 3D scanning applications, like the French company Chat3D we recently interviewed.

Yukhin sees these solutions as complementary rather than threatening.

“There are a few startups already successful with iPhone apps using photogrammetry,” he explains.

Artec 3D integrates photogrammetry into its own software, but Yukhin notes that smartphone-based solutions cannot match the accuracy of dedicated scanners.

“Apps are not really competition because the results are not comparable. But they’re increasingly used for documentation by companies and private users.”

In the meantime, Artec 3D aims to maintain its lead by leveraging its in-house production and years of specialization—continuously refining high-precision, easy-to-use 3D scanning tools that support the creation of ever-more accurate digital models.

Read our story

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)