Dimensional metrology is the branch of metrology that allows for the definition of the shapes, contours, and dimensions of an object. It ensures the accuracy and reliability of measurements in many fields. Our DirectIndustry expert Alain Cruz, Ph.D. in physical chemistry of materials, shares what he sees as the major trends in this sector in the coming years, from ultra-fast scanners to artificial intelligence.

Metrology, the science of dimensional measurement, is used to ensure that a manufactured product conforms to its original design. Several tools have been developed to inspect and measure a wide range of products, from small components for the watch industry to large parts in the aerospace and automotive sectors.

In recent years, increasingly accurate, high-performance, and portable tools have brought metrology out of the laboratory and onto the production line. The sector is undergoing a new revolution, thanks in particular to artificial intelligence.

1/ Scanners Directly Integrated Into Production Lines

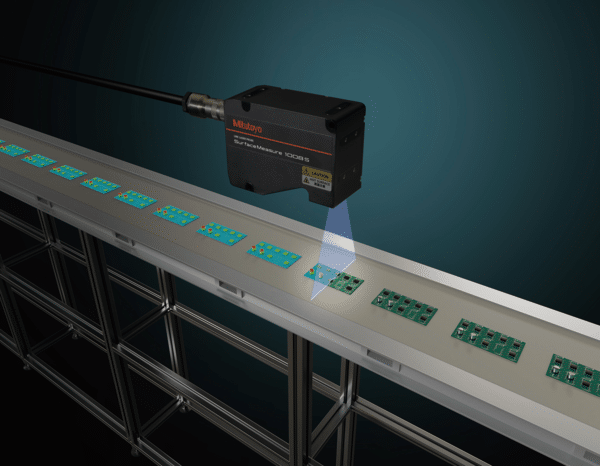

The great revolution in metrology has been to bring the discipline closer to the production line, while before, analyses were done in the laboratory. The trend now is to go even deeper and become part of the production line. There are new “metrology grade” scanners directly integrated into production lines capable of scanning parts at ultra-fast rates and recognizing any defects.

We are witnessing a fusion between machine vision and metrology. Up until now, only machine vision, thanks to megapixel cameras, made it possible to quickly identify different shapes of parts, poorly glued labels, and bad inscriptions and to separate bad products from good products. Metrology, unlike machine vision, can accurately scan parts at levels of detail down to the micron scale and, for example, determine the surface condition of a part, like whether it is smooth or rough. Until now, the instruments were not able to handle speed. This is why it is usually necessary to take a sample of a part for analysis off the production line and not on the production line.

New scanners like the Mitutoyo SurfaceMeasure 1008S for inline inspection allow machine vision and metrology to be combined on the same production line. This type of scanner enables the measurement of the roughness of a surface while being ultra-precise, 20 microns for example with a margin of error of only 0.5 microns while handling very fast rates. The frame rate is of the order of 10 kHz. That corresponds to 10,000 line scans per second (and it takes several lines to form an image). With a 1,024-line image, that’s 10 frames per second. With this type of equipment, all the parts that run on the line will be scanned and not only a sample. This is real progress

2/ AI Makes Metrology Accessible to Non-Metrologists

Another important trend in metrology is the arrival of instruments equipped with artificial intelligence algorithms. These new tools allow non-experts to quickly analyze parts and deduce results.

This is the case of an instrument developed by Bruker Alicona. Their 3D scanner can measure the roughness of surfaces. For the moment it is semi-automatic because it is not 100% integrated into the production line. A sample has to be taken out. But once it is scanned, the machine is able to tell if the sample is good or not. You don’t need to be an expert in metrology. The AI integrated into the scanner allows a quick analysis of the part and deduces an interpretation. And that speeds up decision-making.

The company Deltamu has developed Optimu software to help traditional metrologists and quality specialists quickly interpret the results of measurements so that they can make decisions more quickly.

Ametek-Creaform’s Metrascan 3D scanner also illustrates the process of simplifying three-dimensional analysis for operators without metrology qualifications.

3/ 3D Scanners Will Soon Understand What They Scan Thanks to Deep Learning

AI is also revolutionizing 3D scanners thanks to deep learning. By teaching them to recognize different materials, surfaces, fabrics, and roughnesses, 3D scanners will be more and more able to scan and recognize these materials without the need for manual calibration. The calibration of a device is a tedious but essential step to be able to scan different materials and has, until now, been done by an operator. Today, 3D scanners like the Artec Leo 2022 developed by ARTEC 3D allow the scanner to self-calibrate without human intervention.

The applications of this type of equipment are significant. For example, in aviation, the type of scanner could recognize that it is scanning the exterior of an aircraft and thus be able not only to detect dents on the aircraft’s surface but also to determine which ones require immediate intervention.

In the auto industry, the scanner could check whether the seams of seats are straight enough. Currently, an operator must often use a ruler to determine if this is the case, which can lead to errors. It is conceivable that in the future the scanner could indicate in red, for example, what is not straight. One can even imagine introducing the notion of color. In this case, the machine would indicate whether the color of the leather of the car seat was in accordance with the expectations and design specifications.

3D scanners are continuing to evolve rapidly, with improvements in accuracy, speed, portability, material scanning, integration with other technologies, and the use of AI. These developments will enable new applications for 3D scanners and better metrology solutions for companies.