In Aesch, Switzerland, BWT Pharma & Biotech recently inaugurated the expansion of its production site. This hub of engineering and innovation is dedicated to water treatment for pharmaceutical and biotechnological industries. This facility, a showcase of the expertise of the Austrian group BWT (Best Water Technology), reflects the international expansion strategy of the European leader in water treatment. DirectIndustry visited the site and met the management team.

A Global Player with a Technological DNA

With a turnover of €1.4 billion, more than 6,000 employees, 12 production sites worldwide, the group has become a major player in its sector. Among its divisions is BWT Pharma & Biotech. Originating from the historic Christ subsidiary, a leader in pharmaceutical water treatment since 1992, this entity is now entirely dedicated to the pharm and biotech sectors.

It employs 600 people, serves over 2,000 clients worldwide, and relies on a global industrial network. Production sites are in Boston, Dublin, Malmö, Shanghai, and Aesch, a site visited by DirectIndustry, which was recently expanded. This 2024 expansion meets the growing demand for high-performance water treatment solutions

“We do only one thing: water treatment. But we do it at the highest level to guarantee the best water in the world,” emphasizes Pierre Cullmann, Pharma & Biotech Market Manager at BWT France.

But how do they achieve this? Cullmann explained the group’s strategy, particularly for the pharmaceutical division, where there is no margin for error.

Water Quality: An Absolute Imperative

In the pharmaceutical industry, water quality is essential. Whether producing vaccines, antibiotics, or paracetamol, pharmaceutical manufacturers require water that meets strict standards in line with global pharmacopoeias—European, American, and Chinese. In this sector, any deviation can lead to production halts or health risks. Ensuring water quality and the reliability of the systems managing it is therefore critical.

BWT designs and manufactures treatment skids capable of transforming regulatory-grade potable water into purified water (PW) or water for injectable preparations (PPI/WFI), while maintaining its physicochemical and microbiological quality all the way to the client’s production line.

A Comprehensive Technological Portfolio

To enable that, BWT offers a complete range of technologies covering the entire water treatment cycle. For purified water, BWT provides softeners, reverse osmosis, electro-deionization, and spiral-wound electro-deionization modules.

For water for injectable preparations, clients can choose natural circulation distillation, thermocompression distillation, or membrane technologies, now recently authorized by the European Pharmacopoeia.

Additionally, BWT produces pure steam generators used to sterilize containers, bags, needles, and equipment. The company prides itself on being the only European producer of spiral-wound electro-deionization modules. This technological mastery provides BWT with a significant competitive and strategic advantage. And unlike many competitors, BWT does not replicate solutions across different sectors.

“We don’t make the same machines for microelectronics and pharma. This specialization creates the value and expertise our clients seek,” he insists.

Every machine is designed for a GMP environment and can be validated through Factory Acceptance Tests (FAT) and regulatory qualification processes.

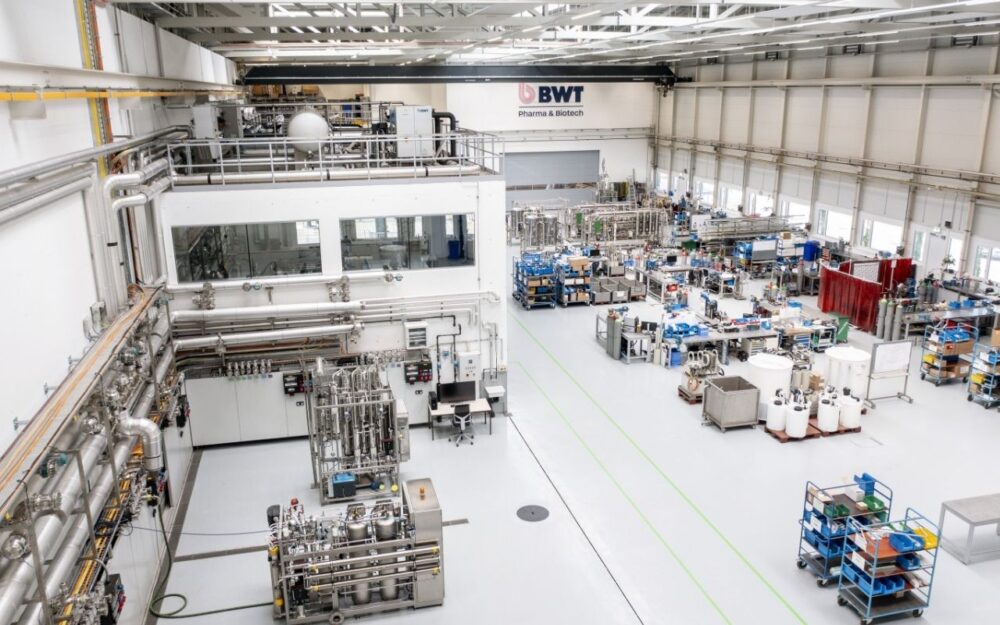

The Aesch Plant: An Industrial Showcase

At the heart of operations, the Aesch site is a true center of excellence. It spans 1,280 m² entirely dedicated to pharmaceutical production and includes three FAT zones, enabling full-capacity testing of installations before delivery.

“Our job is to support the client from start to finish: from design to delivery, including validation and maintenance of the installation. When we build a machine, the client will not accept it without proof that everything has been tested and validated at 100%. We fill the machine with water, operate it, and verify its real performance,” explains Cullmann.

These tests can last from one day to two weeks depending on equipment complexity. Each FAT zone can accommodate two machines, allowing up to six simultaneous tests, with flows reaching 40 m³/h of purified water or 6.2 tons of pure steam per hour. The company says these capacities are unprecedented in Europe and allow BWT to simulate real operational conditions, guaranteeing full compliance before shipment.

“Without FAT, no equipment is accepted in a pharmaceutical plant,” he adds.

Innovation and Sustainability Integrated into Design

Beyond technical performance, the Aesch site embodies the group’s sustainability philosophy. The plant was designed to maximize energy efficiency, minimize water consumption during machine testing, and reduce the carbon footprint of production, including the company’s own operations during testing cycles.

“You cannot advocate innovation in water treatment while wasting your own resources. That’s why we designed a complete recirculation system,” Cullmann explains.

Water used in tests is partially reinjected, steam heat is recovered, and wastewater is either reused or returned to the local aquifer. This circular approach significantly reduces the demand for fresh water.

Gabriel Roth, Business Director at BWT, adds:

“During the first tests, we consumed about 50,000 m³ of water over six months. Through optimization of rinsing, recirculation, and recovery, we significantly reduced consumption. Clients notice this and often ask to replace installations before their end-of-life to gain water efficiency.”

Carbon footprint reduction is also a key priority. Distillation and steam production technologies are evolving toward less energy-intensive solutions aligned with the pharmaceutical industry’s carbon neutrality goals.

“Industrial steam used for distillation can account for up to 30% of a pharmaceutical site’s carbon footprint. We have therefore developed electrical and membrane-based alternatives to reduce this impact,” Cullmann continues.

Automation, Data, and Cybersecurity

Innovation at BWT goes beyond water. The company emphasizes an expertise-oriented service model, supporting clients not only in installation and maintenance but also in validation and qualification of systems. This is particularly critical for highly audited pharmaceutical operations. Each machine now integrates smart supervision, connected metrology, and predictive maintenance tools.

“We are the only company with teams dedicated to large-scale validation. Our engineers almost spend more time qualifying systems than maintaining them,” Cullmann notes.

This approach addresses a major challenge for pharmaceutical clients: data traceability and regulatory compliance. Agencies such as the FDA increasingly penalize data management failures.

“Most warning letters result from errors in data management or falsification. That is why our discussions with clients focus as much on cybersecurity and automation as on water quality,” he emphasizes.

BWT’s solutions ensure not only compliant water but also complete control over production data, guaranteeing reliability and regulatory compliance throughout the lifecycle of installations.

Toward Global Leadership

Already the European leader with 40–75% market share depending on the country, BWT Pharma & Biotech now aims to become the number one global player by 2030. To achieve this, the group relies on country-specific divisions to maintain close client relationships and responsive expert support.

Recent acquisitions, such as GDN in Italy (2022), the Aesch expansion (2024), and the creation of a global BWT Pharma & Biotech division (2025) illustrate this strategy of international growth and industrial strengthening.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)