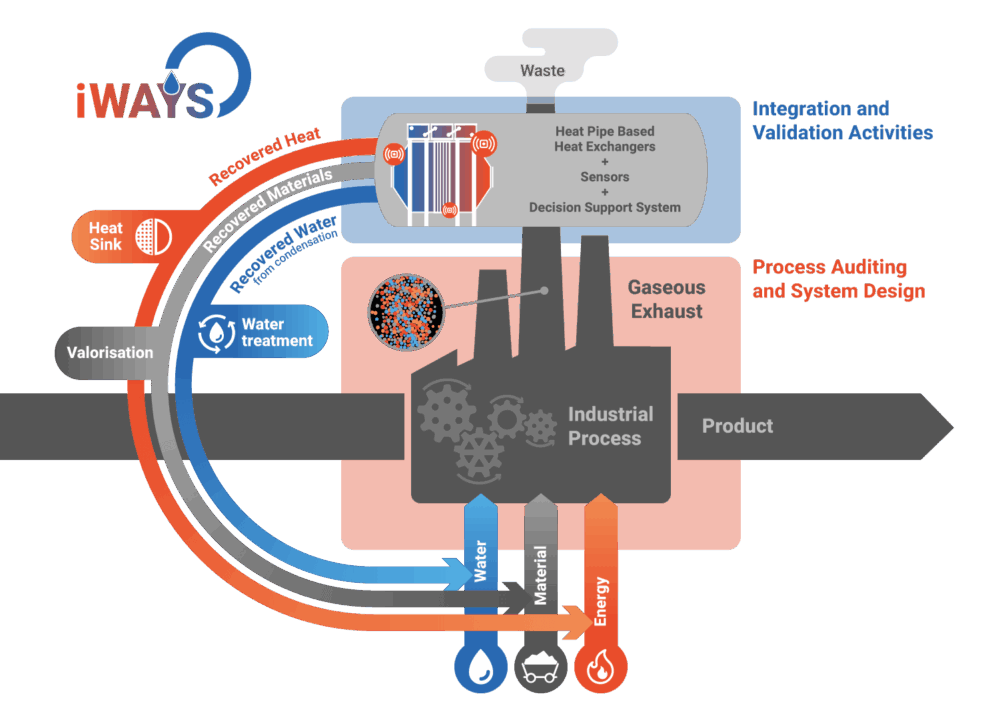

The efficient recovery and utilization of waste heat represents a significant potential for enhancing energy sustainability in energy-intensive industries. The EU-funded iWAYS project is actively developing technologies to address this potential. Robertas Poškas, a thermal engineer at the Lithuanian Energy Institute (an iWAYS partner), offers valuable insights into the project’s work, the importance of diverse heat sources, and the future of industrial heat recovery.

This interview has been edited for length and clarity.

What is your specific contribution to the iWAYS project and what aspect are you most proud of?

Robertas Poškas: “In the Lithuanian Energy Institute, we tested the Heat Pipe Condensing Economiser. For that, we created a test section where we were able to supply acidic flows that are specific to certain industries and that affect their heat exchangers. We tested the resistance of the internal components to corrosion. Additionally, we investigated the condensation process in the Heat Pipe Condensing Economiser. In my point of view this is a very promising technology; it specifically fits to industry.”

Why is the diversification of heat sources important for modern energy systems?

Robertas Poškas: “It’s very important for Europe because instead of importing a lot of external resources like gas and so on, we can use local products like waste heat and other sources which are cheaper. If you look globally, it is good for industries to recover resources such as heat, because this is affecting the final product price.”

What trends do you foresee in the future of heat sources for energy intensive industries such as steel, chemicals or cement?

Robertas Poškas: “All industries need the same to retrieve or recover waste heat, water, and other materials as much as possible. Therefore, there is worldwide action to bring small modular reactors to the market. More advanced technology is needed to store heat for a longer period. I have heard of some countries replacing conventional boilers with electric ones, which is a game changing step; they do not pollute environments and allow businesses to meet CO2 requirements.”

How can industries transition from fossil-based heat sources to more sustainable options without compromising activity?

Robertas Poškas: “All of industry is trying to be more sustainable. They’re installing condensing economisers, heat pumps and heat accumulators. The technologies being developed in the iWAYS project are very important as well, because they are real products (condensing economisers, water purification systems) that are getting installed in real plants, in real conditions. You can see what is happening in real time and improve the equipment.”

What do you see as the biggest challenges and opportunities for the iWAYS project moving forward?

Robertas Poškas: “Now it will be a big challenge to install heat pipe condensing economizers into the demo cases, to run them and see what is happening. In reality we can encounter various issues, but it is normal. Small-scale laboratory testing does not fully reflect real conditions. They can be improved by large-scale prototype testing because we can improve equipment in the laboratory. For example, we can add some coatings to the heat pipes and carry out additional tests.”

What is your motivation behind participating in iWAYS?

Robertas Poškas: “In this project we are dealing with real products which are installed in real industrial plants and operated under real conditions. It’s not mock-ups or prototypes like in other similar projects; in our case we have real products. It’s a good example for other organisations wanting to carry out such type of projects.”

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)