Hungary-based AX System is redefining workplace safety with smart, modular technology. We spoke with Gabor Nemes, the company’s CEO.

In a fast-moving warehouse environment, the smallest distraction can lead to a major accident. That’s exactly what happened to Gabor Nemes, a former forklift driver who narrowly avoided a tragic incident.

“If I had braked just one second later, I could have killed my supervisor,” recalls Nemes, now CEO of AX System, a Hungary-based industrial safety tech company. “That moment changed everything for me.”

From this near-miss, Nemes envisioned a solution: an AI-powered vision system that not only sees what the human eye can’t, but also responds instantly to prevent accidents.

READ ALSO

An AI-Driven, Local Ecosystem for Safer Workspaces

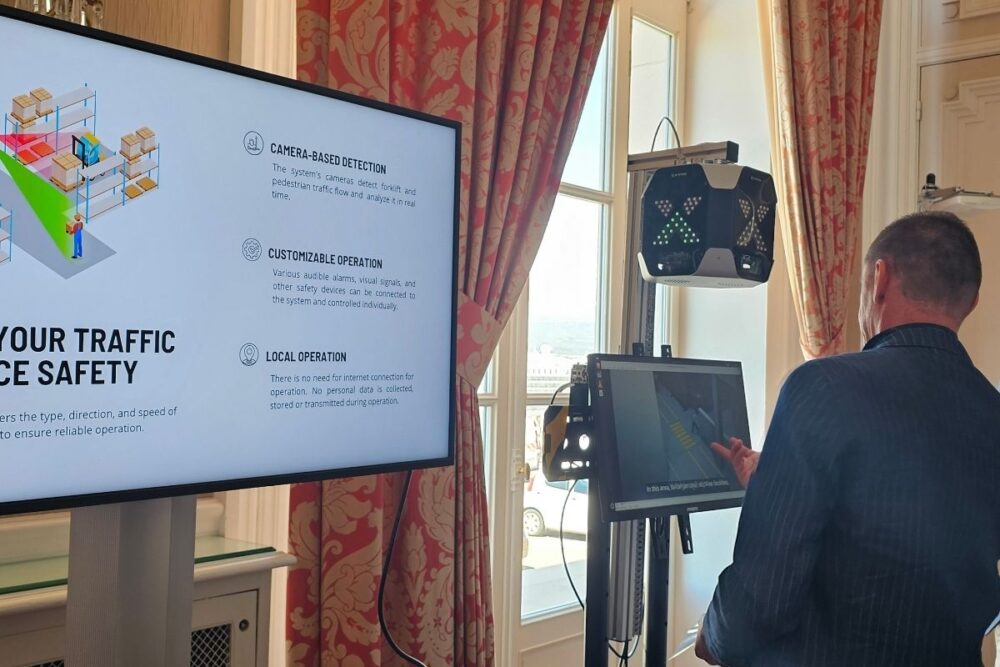

AX System’s solution is not just a single device—it’s a holistic ecosystem combining cameras, sensors, and control software to monitor traffic flow and detect danger. To meet the diverse needs of industrial clients, AX System offers two scalable solutions:

The Cube: A plug-and-play device ideal for small or medium-sized risk zones. All sensors and processing are housed in a single unit.

The Modular System: A customizable setup with distributed cameras and sensors, all linked to a central control cabinet. Ideal for large, complex sites.

“Some areas only need one camera. Others need five. We tailor the system based on real risk—not floor size,” says Nemes.

Every component, from sensor placement to AI rules, is designed with the end-user’s real-world needs in mind.

“Every site is different and every risk is unique. That’s why we don’t sell a product—we deliver a solution,” he says.

Unlike many surveillance systems, everything is processed locally, without reliance on the cloud.

“We don’t stream data to servers. All analysis happens onsite. That means instant reaction—no delays,” Nemes emphasizes.

This architecture makes the system reliable, fast, and secure, especially for mission-critical applications like logistics hubs, factories, and warehouses.

Real-Time Risk Detection That Only Alerts When It Matters

One of AX System’s most distinctive features is its smart alerting mechanism. Traditional warning systems can desensitize workers with constant false alarms.

“When a yellow light flashes 100 times a day for nothing, people stop noticing it,” says Nemes. “Our system only alerts when there’s real danger. That way, the red light means: take this seriously.”

Using AI object recognition, the system detects approaching forklifts, pedestrians, or other moving machinery—and calculates their trajectories to predict possible collisions. Depending on the environment, it triggers LED signs at eye level (ideal for silent zones), audible alarms or horns (effective in noisy settings) or projected signs on the ground (for high-traffic visibility).

READ ALSO

The System Acts Like a Human Co-Worker

AX System uses human behavior as a design model. Nemes describes the architecture in vivid terms:

“The camera is the worker’s eyes. The buzzer is their voice. The lights and projections are their hands. Our system becomes a co-worker—one who sees the danger before it happens.”

For instance, the system can be programmed to detect a pedestrian approaching a blind corner and project a flashing red stop symbol for the forklift driver—while simultaneously issuing a green light for the pedestrian.

The technology is already being used in 10 European nations, by major industrial players such as Schneider Electric, Bosch and Mercedes-Benz in their warehouse.

Nemes confirms that interest from smart cities has also increased, but notes that warehouses are currently a better fit:

“Urban environments are too complex—cars, weather, pedestrians all at once. Warehouses offer the perfect conditions for high-accuracy systems.”

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)