Additive manufacturing company Sculpteo is introducing a new high-performance, food-safe 3D printing material. While PA12 Blue is designed for the food industry, it also has potential applications in other sectors that require strict industrial standards such as medical and pharmaceutical industries.

The food industry faces ever-increasing demands for hygiene, traceability, and safety. As manufacturers seek innovative materials that comply with strict regulatory standards while maintaining high performance, Sculpteo has introduced a game-changing solution: PA12 Blue, a food-grade polyamide designed for additive manufacturing in critical industrial environments.

With its high durability, compliance with EU food safety regulations (CE 1935/2004 and CE 2023/2006), and enhanced visibility for quality control, PA12 Blue could revolutionize the use of 3D-printed components in sectors where cleanliness and safety are non-negotiable.

A Material Designed for Food Safety

The striking blue color of PA12 Blue is more than just an aesthetic choice—it serves a crucial safety function. Since blue is rarely found in natural foods, any small fragments of material can be quickly detected during quality control. This helps prevent contamination risks and reinforce food safety protocols.

Beyond its color, PA12 Blue boasts exceptional mechanical properties thanks to Selective Laser Sintering (SLS) technology. The material offers high wear resistance, impact strength, and thermal stability. This is ideal for demanding industrial environments. Additionally, its resistance to aggressive cleaning agents ensures durability in settings where strict hygiene protocols are required.

For even greater performance, PA12 Blue can undergo chemical smoothing, enhancing surface finish and reducing porosity. This treatment makes the material easier to clean and prevents bacterial buildup.

Applications for High-Demand Industries

While PA12 Blue is specifically developed for food-related applications, its properties make it highly versatile for other industrial uses where strength, durability, and compliance are essential.

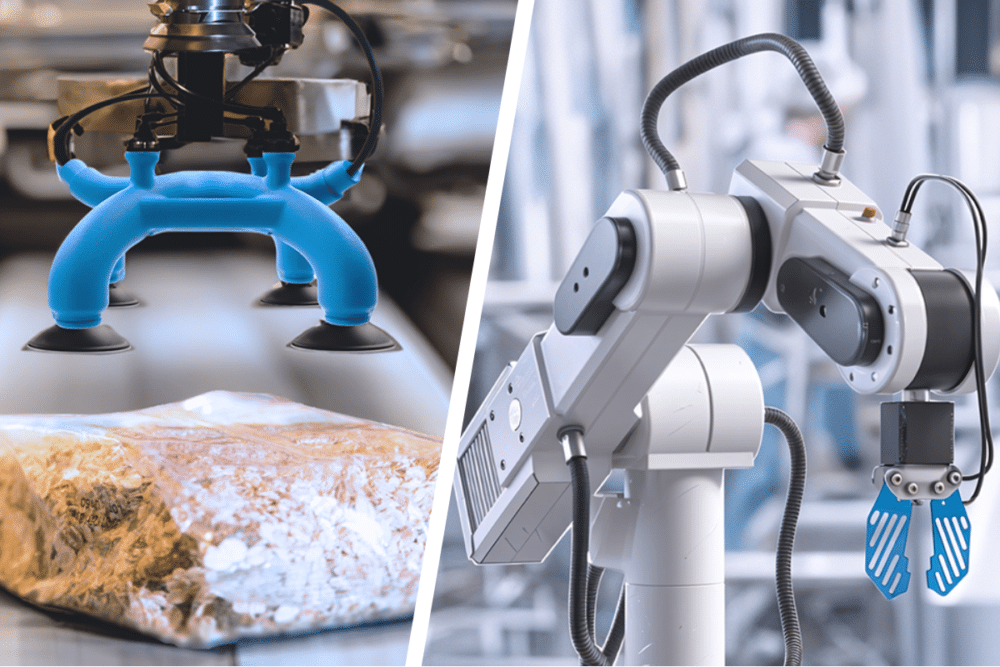

For example, this material is ideal for gears, cutting guides, and conveyor components. These food processing equipment indeed require high endurance.

PA12 Blue is suitable for containers and trays that must be robust and easy to sanitize. It can also enable the creation of industrial molds, assembly jigs, and handling tools for controlled environments.

As said before, PA12 Blue is easily identifiable so manufacturing components with this color enhances maintenance and inspection and reduce human errors. This is a key advantages for applications in the pharmaceutical, and medical industries.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)