Breaking down PET plastic into its original building blocks, while allowing PLA bioplastic to compost at lower temperatures, Carbios’ enzymatic recycling technologies are a major advancement in the circular plastic economy.

Plastic is one of the world’s most pervasive and toxic pollutants, with the United Nations warning of a “toxic tidal wave” as the world generates 400 million tonnes of plastic waste each year.

A Toxic Tidal Wave

Around 99% of this plastic is made from fossil fuels, such as PET (polyethylene terephthalate). The rest is bioplastic such as PLA (polylactic acid), made from organic sources like corn starch and sugar cane.

RELATED ARTICLE

To combat plastic pollution, the European Union has issued a Single-Use Plastic (SUP) Directive. It is also pushing for plastic to have a more circular and sustainable lifecycle. For example, all packaging in the EU must be reusable or recyclable in an economically viable way by 2030.

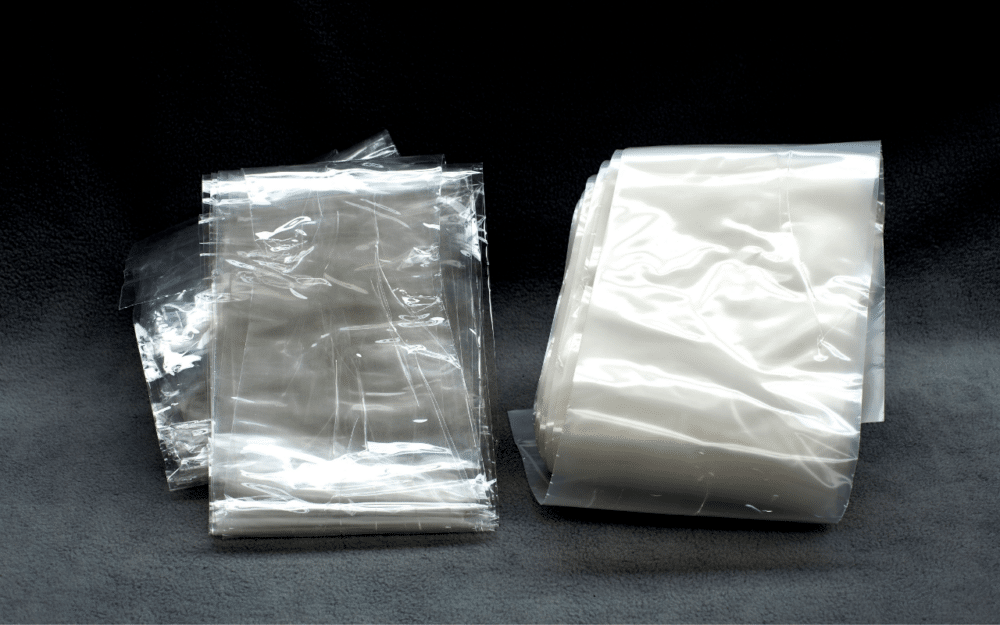

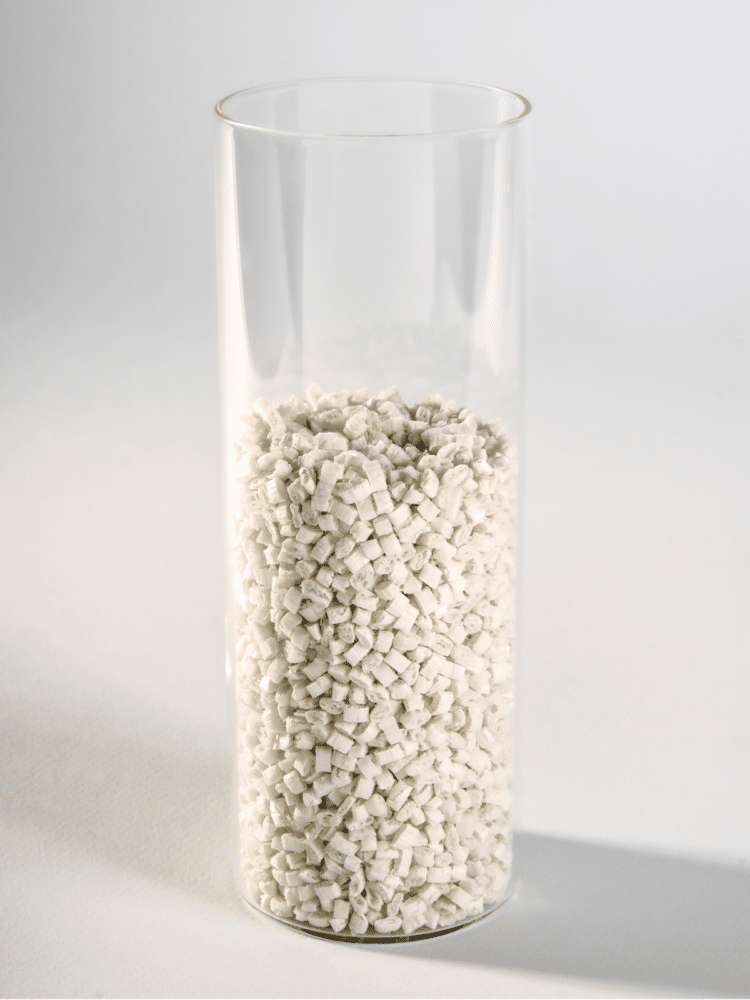

Currently, PET waste such as plastic bottles is typically processed using thermomechanical recycling – which shreds, washes, and melts the plastic into pellets for making new products.

After being thermomechanically recycled several times, plastic quality degrades to the point where it cannot be reused, after which it generally ends up in a the landfill.

Another key use of PET is the production of polyester fiber for clothing. More than 60 million metric tons of polyester is produced every year, most of which is dumped into landfill or burned after it is discarded.

To drive the circular economy, Europe is set to ban the destruction of returned and unsold textiles and footwear.

RELATED ARTICLE

Enzymatic Recycling Process

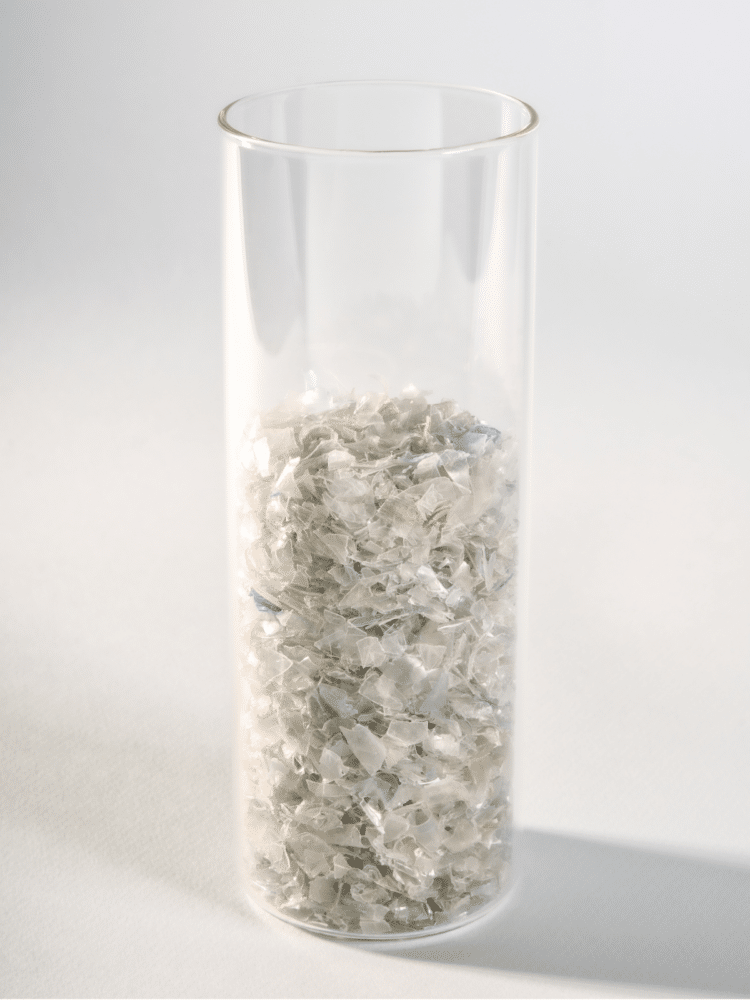

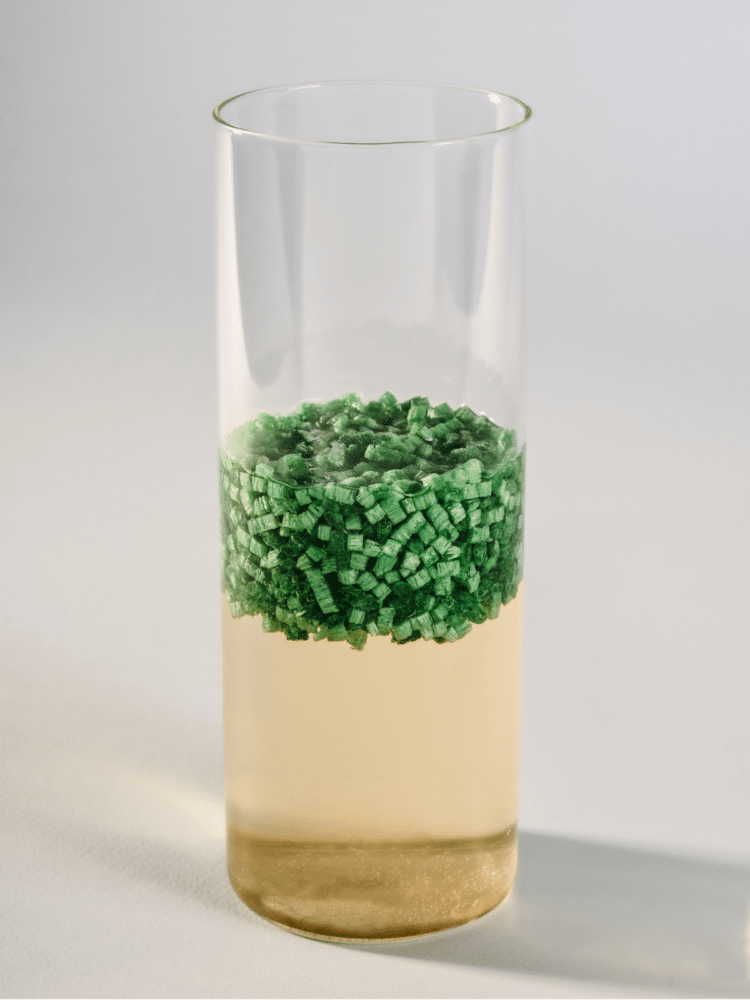

Rather than melting PET to recycle it, enzymatic recycling uses proteins that act as biological catalysts to accelerate chemical reactions. This depolymerises the plastic, breaking it down into its original building blocks, so it can be used to create new products of equal quality to those made from virgin PET.

Whereas thermomechanical recycling only handles clear plastic, enzymatic recycling allows for the recycling of all types of PET waste, including colored, multi-layer, and polyester textile waste. As an added benefit, enzymatic recycling also offers a higher yield rate, with 100 kg of PET waste producing 90 kg of virgin PET.

The first of its kind in the world, Carbios’ enzymatic recycling process was recently recognized in a scientific paper published in the prestigious journal Nature.

For every tonne of PET recycled, the use of 1.3 tonnes of petroleum is avoided. Carbios’ process reduces CO2 emissions by 57% compared to producing virgin PET from scratch, says Carbios CEO, Emmanuel Ladent. Carbios is seeing great interest from manufacturers as their customers demand greater use of recycled plastic to reduce environmental harm, Ladent says.

“What we produce is totally plug-and-play compatible with the existing plastic industry, because it is exactly the same as the virgin PET they already use.”

Much of the world’s plastic and polyester manufacturing is based in Asia and Carbios has signed a letter of intent with Zhink Group to build a recycling plant in China. It has also struck a partnership with cosmetics giant L’Oréal, with interest from the likes of PepsiCo, Nestlé Waters, and Suntory.

Carbios operates its own small recycling plant in Longlaville, in north-eastern France, which is strategically located close to the borders with Belgium, Germany, and Luxembourg. It plans to eventually license the technology around the world.

“The idea is to bring the enzymatic recycling plants as close as possible to the sources of recyclable plastic. Reducing the distance that a used plastic bottle needs to travel, before it can be recycled, further helps reduce its carbon footprint.”

Carbios’ PET Bio Recycling Full Process

Examples of Applications

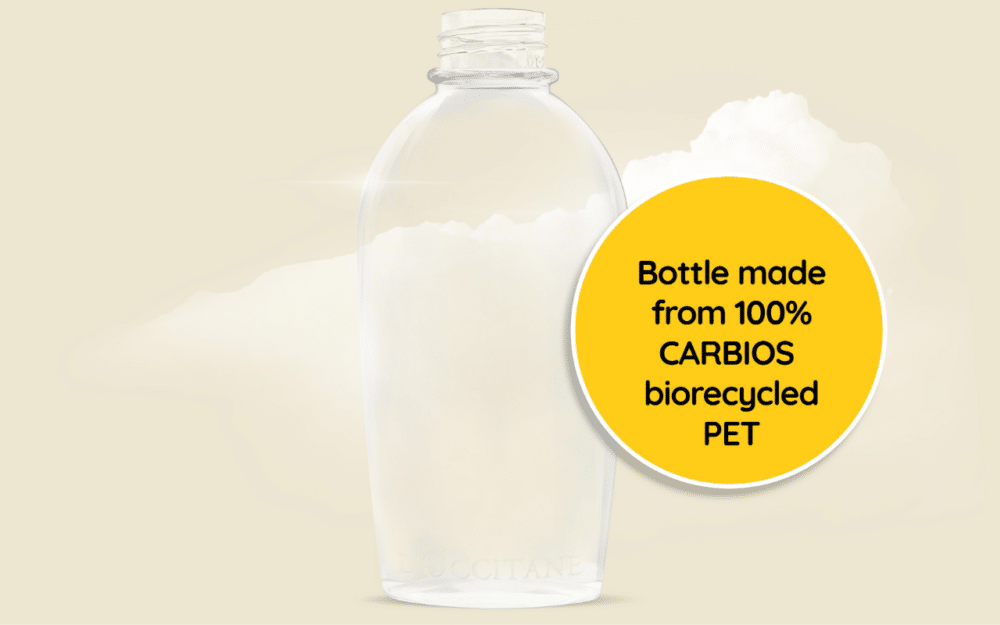

The First Enzymatically Recycled Bottles

Recently, L’OCCITANE en Provence and Carbios presented a PET bottle made from enzymatic recycling.

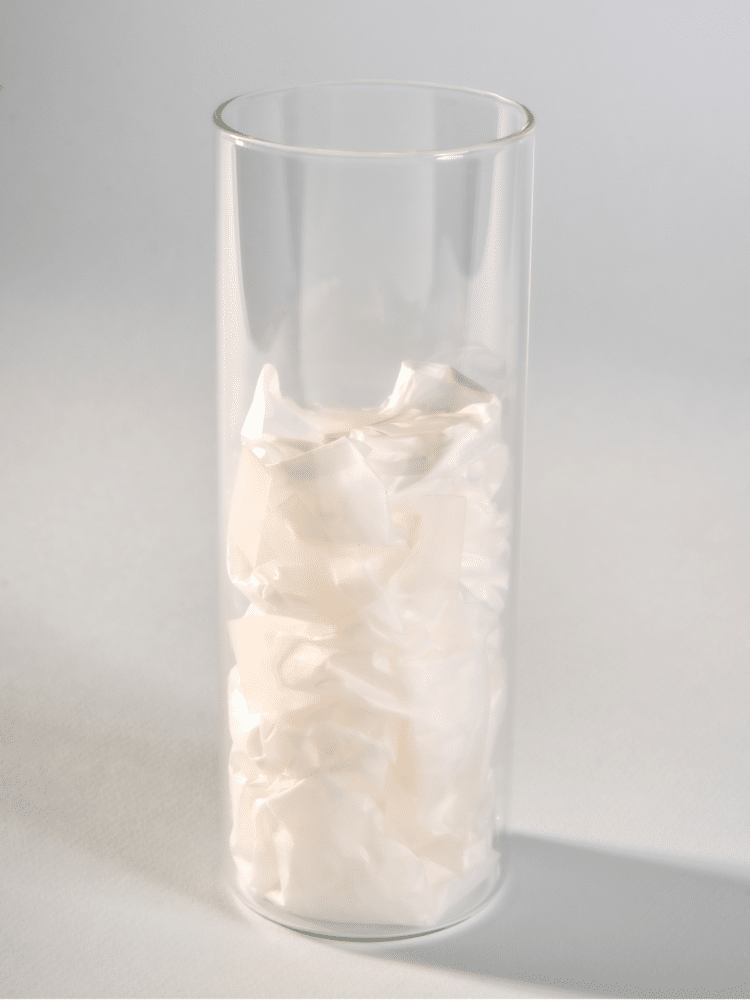

PLA and Carbios Active

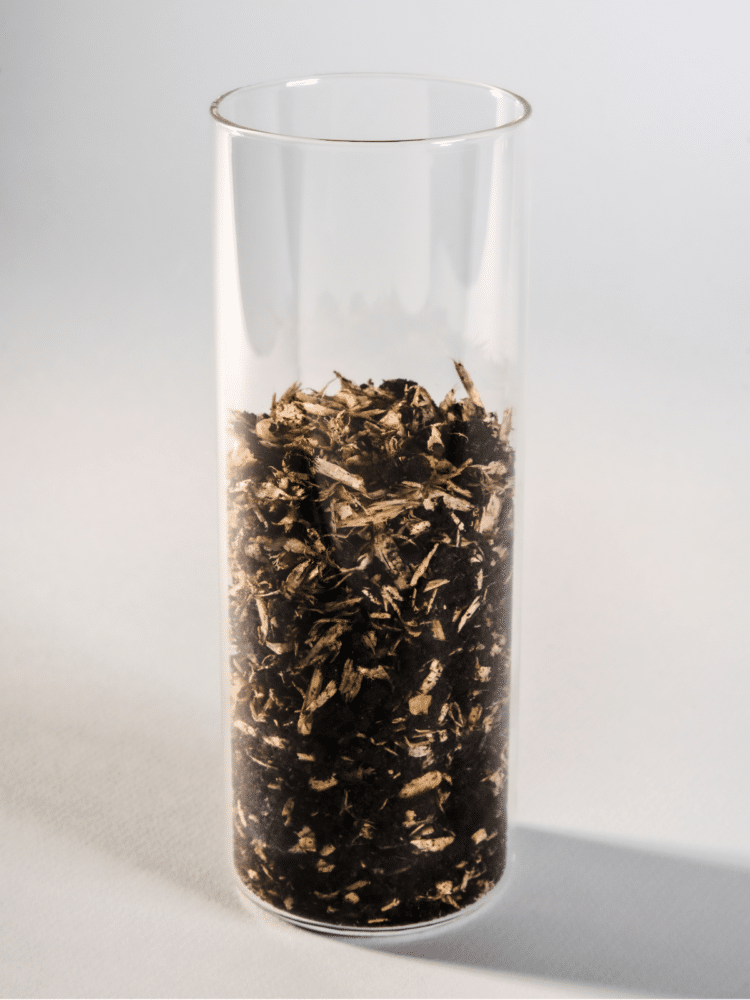

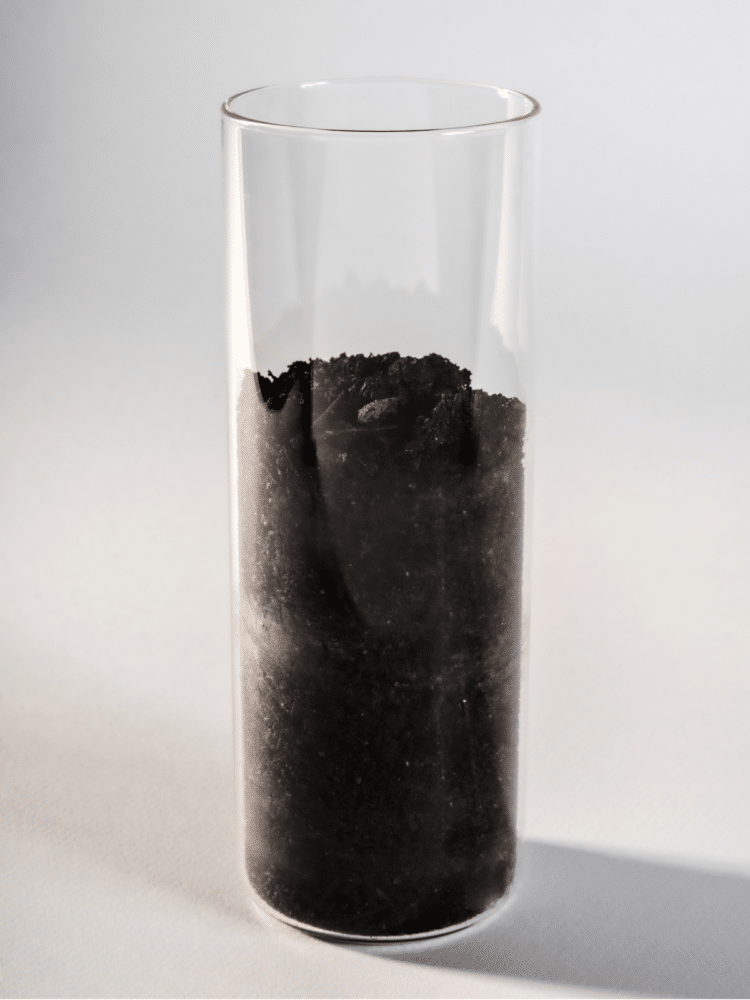

Along with enzymes for breaking down PET during recycling, Carbios developed what they call Carbios Active. They produce enzymes that can be added to PLA bioplastics during manufacturing. These enzymes ensure used PLA plastic can be composted at home, rather than requiring high-temperature industrial composting conditions.

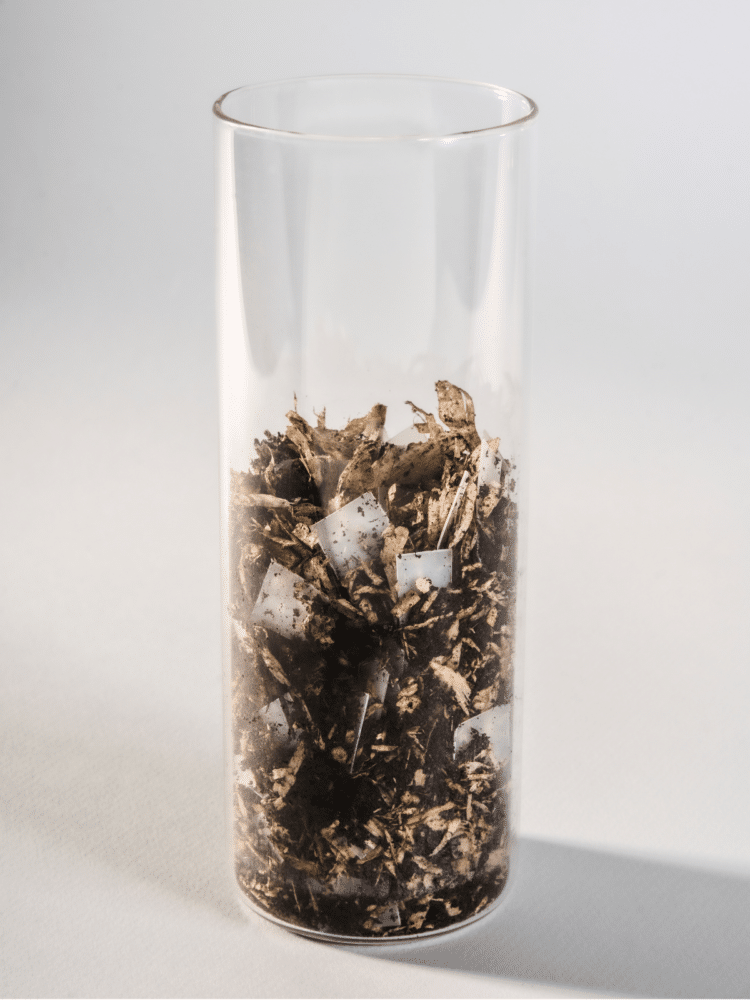

The result is complete disintegration and biodegradation of PLA plastic, producing residue-free, non-toxic compost within only 12 weeks, Ladent says.

“While traditional PLA bioplastic is compostable in the right conditions, much of it doesn’t make it to the industrial composting plants. This can give people false confidence when choosing bioplastic over traditional plastic. Our enzymes give manufacturers and consumers peace of mind, knowing that compostable PLA bioplastic such as food packaging will actually compost the way you would expect it to.”

The PLA Biodegration Full Process

Examples of Applications

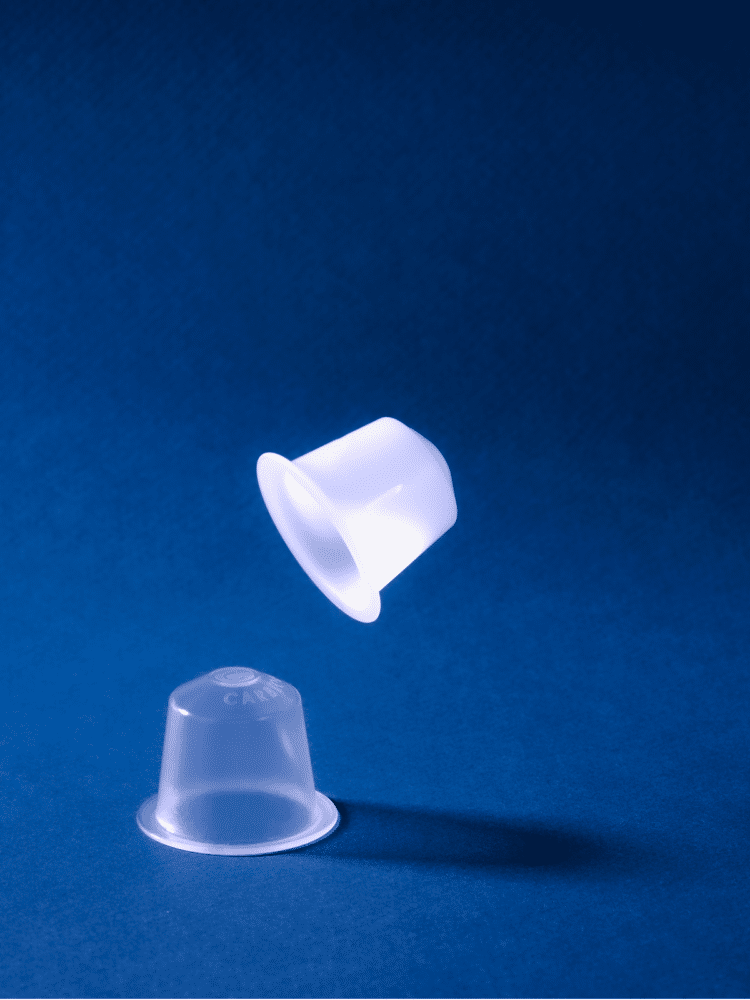

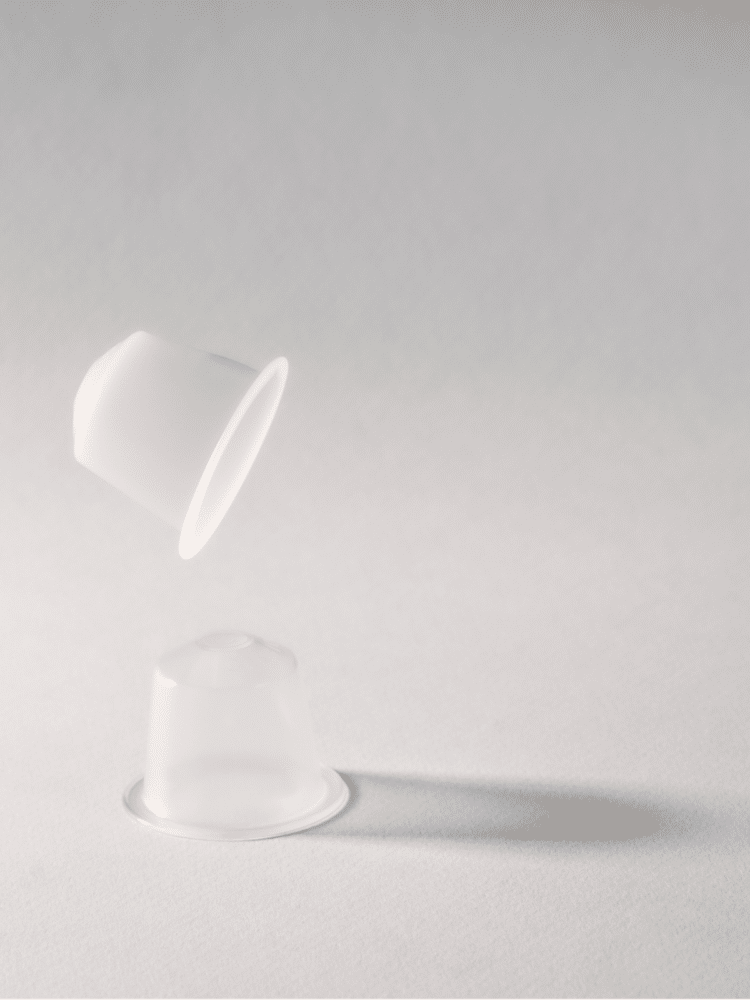

1/ Coffee Capsules Made From PLA and Carbios Active

2/ Compostable Air Cushion

3/ Compostable Food Tray

4/ Compostable Films