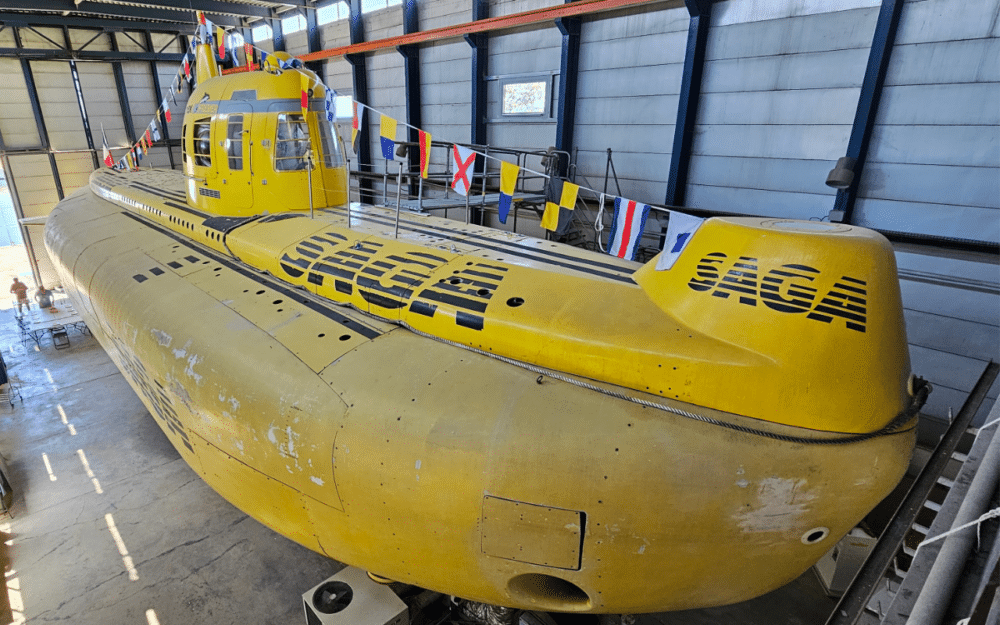

Imagined by Captain Cousteau and built for the oil industry by COMEX, the SAGA (formerly Argyronète) has been in a hangar in Marseille since the 1990s. We had the chance to board and dive into the history of this innovative underwater technology gem, which unfortunately did not achieve the commercial success it was hoped for. Here is our report.

Astrid Aguëra contributed to this report.

We didn’t have to go far. The hangar housing the yellow submarine is only a few kilometers from DirectIndustry’s editorial office. Since the 1990s, the SAGA (in French Sous-marin d’Assistance à Grande Autonomie), the Long-Range Assistance Submarine imagined by Jacques-Yves Cousteau in the late 1960s under the name Argyronète has been sleeping in L’Estaque, Marseille.

The idea for an underwater habitat came from Jacques-Yves Cousteau in the 1960s. The famous French oceanographer wanted to allow divers, explorers, and scientists to live underwater at previously inaccessible depths, up to 400 meters, for extended periods. The main objective was oceanography and the observation of aquatic biodiversity.

The Origin: The Argyronète Project

Initial projects, like Précontinent, faced high costs and dependency on surface weather conditions, leading Cousteau to propose a habitat attached to a submarine. In 1966, he asked the engineers at the Center of Advanced Marine Studies (CEMA) to develop a vessel that was not dependent on weather conditions and sea state. The initial project was named Argyronète, after Argyroneta Aquatica. This small aquatic spider is capable of living underwater thanks to its ability to create an air bubble for breathing. Cousteau’s idea was to build an autonomous house under the sea that could function independently, just like this spider.

According to Gérard Dalmas, SAGA Project Engineer:

“Cousteau’s idea was to create a submarine in symbiosis with diving.”

By 1971, construction of the 28-meter-long submarine began. The hull, diesel engines, hydraulic equipment, detachable sphere, and steel regulators were built and assembled in a hangar in L’Estaque, Marseille. However, some limitations were already pointed out: with only 28 meters in length, the submarine was too small to carry surface-rechargeable batteries with a diesel engine. Additionally, doubts were raised about its ability to maintain energy throughout the planned missions.

Budget overruns led the government to cut funding and halt progress. It took until the 1980s for private individuals to take over the project. COMEX, led by its founder Henri-Germain Delauze, took charge. At the time, the Marseille-based company was a world leader in underwater work, a title it competed for with American Oceaneering. COMEX allied with IFREMER (the French Research Institute for Exploitation of the Sea) and IFP (the French Institute of Petroleum) to revive the Argyronète project. However, this time, the goal was to offer a solution for the oil industry rather than marine exploration as Cousteau had envisioned. To achieve this, the submarine would be equipped with innovative technologies to make this solution competitive and efficient.

A Submarine for Offshore Operations

According to Michel Bourhis, former Commercial Director of COMEX Africa and Mediterranean, the offshore industry had high demands at that time. Oil companies were seeking a vessel that would allow divers to work on oil fields down to -450 meters for extended periods, such as 10 days.

The envisioned missions included maintenance of underwater wellheads, such as valve replacements, construction activities like connecting flexible lines, pipeline repair assistance, non-destructive testing, and coring.

The submarine could also carry equipment like ROVs (Remotely Operated Vehicles) to inspect pipelines up to -600 meters, with a range of 140 nautical miles.

There was also talk of missions in Antarctica since oil companies were planning to drill under the ice.

Daniel Balzano worked at the SAGA design office. He explained:

“We retrieved Cousteau’s plans and made new exterior and interior modifications. I worked extensively on hull penetrations, mushroom vents, and hull passages. With the innovative technologies we installed, we tripled the vessel’s autonomy compared to the Argyronète. It went from ten days of autonomy at 100 meters to three weeks of autonomy at 450 meters for diver interventions, regardless of surface weather conditions.”

The submarine, now called SAGA (as Cousteau did not leave the rights to use the name Argyronète), was completed and inaugurated in October 1987 in the presence of the then French Prime Minister Jacques Chirac.

The first sea trials under real conditions began. The objective was to prove that the submarine could indeed perform underwater work at great depths. Initially, it commissioned an outfall at 185 meters depth off the coast of Monaco. In 1990, the SAGA carried out a three-week mission at 317 meters depth for an archaeological mission at Cap Bénat, in front of the French Porquerolles islands.

Innovative Technologies

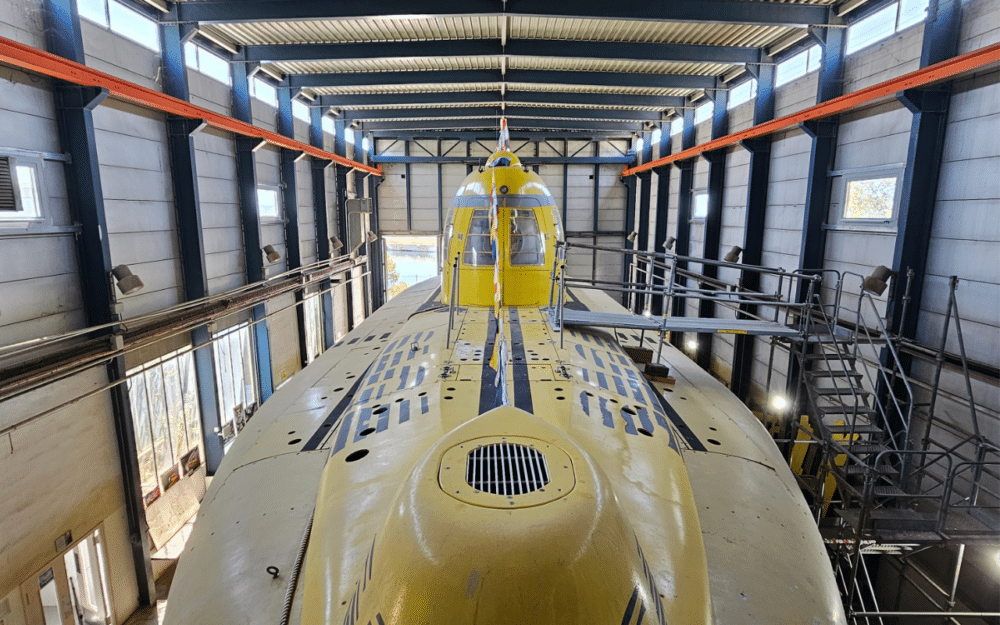

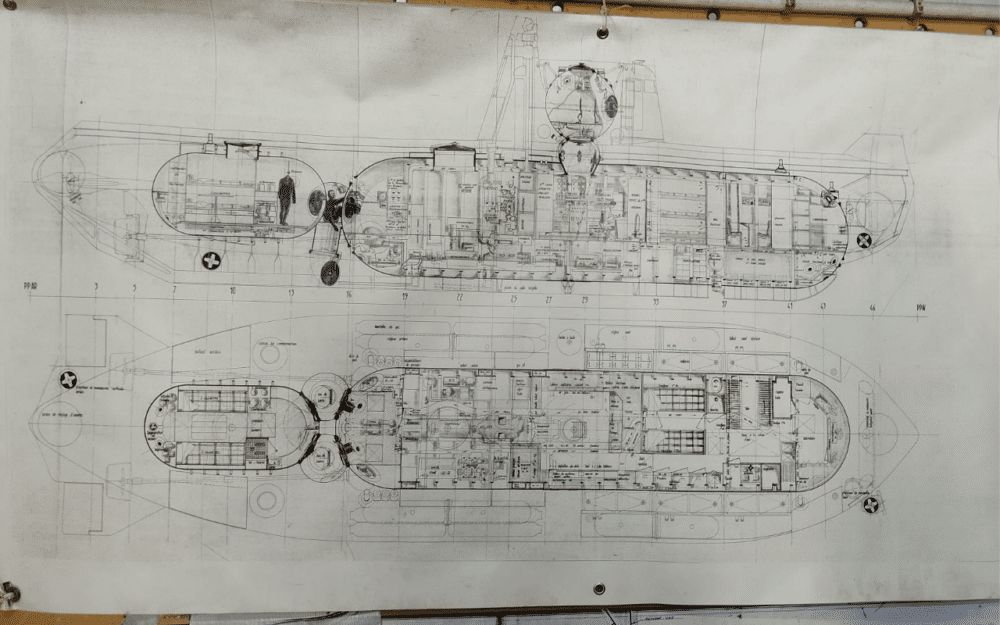

We follow the companions of the SAGA aboard their yellow submarine. Designed to accommodate a crew of six, the SAGA measures 28 meters long, 7 meters wide, and 8 meters high, and weighs approximately 300 tons.

It consists of three parts: an atmospheric pressure compartment housing the six crew members, a hyperbaric chamber for up to six divers (intended for underwater missions on oil installations), and a detachable sphere to evacuate crew members and bring them to the surface in case of an emergency. Divers were to be rescued using a turret to respect decompression stops.

A fiberglass hull (fairing) protected external equipment such as batteries, gas tanks, and piping. The laminated ballast was a notable innovation. This lightweight yet robust material allows the submarine to maintain its buoyancy.

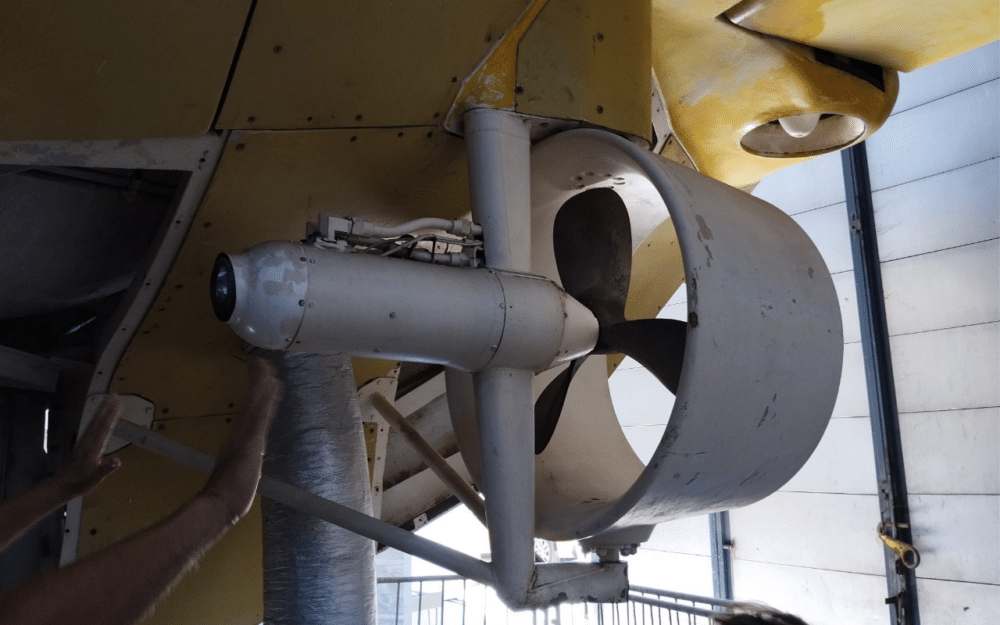

The SAGA submarine features four main innovations, summarized by Michel Bourhis:

“The propulsion system has been improved. The submarine transitioned from a conventional diesel-electric system to an anaerobic Stirling engine. Oxygen and fuel are supplied by cryogenics, meaning they are stored in liquid form at very low temperatures. The diameter of the gas cylinders has been increased, and the pressure has been doubled from 200 bars to 400 bars. A control computer has been installed to manage the submarine’s systems more efficiently.”

Here is a detailed overview of these four major innovations.

1/ Stirling Engines and Liquid Oxygen

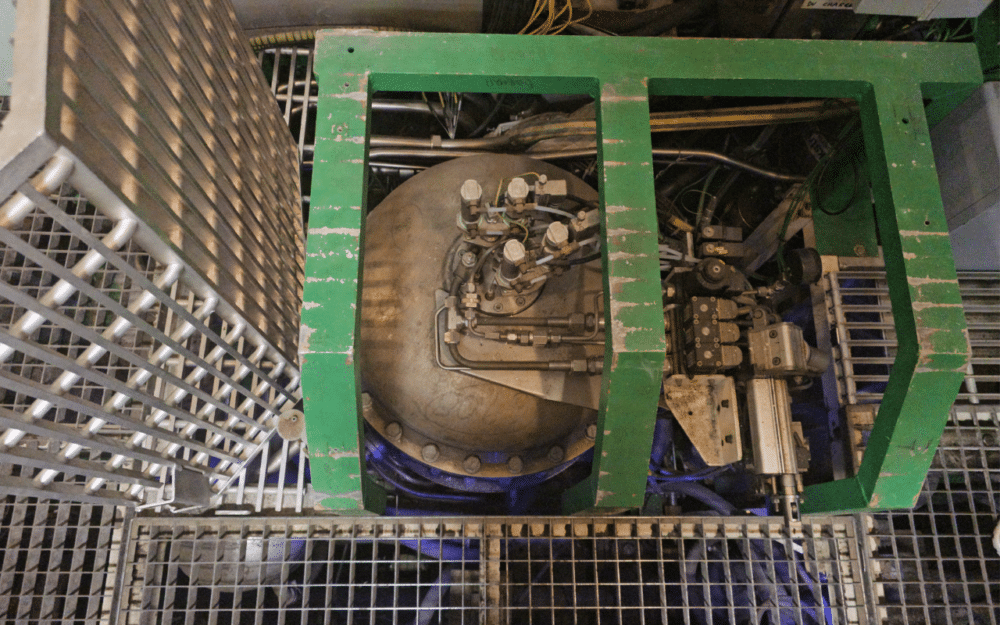

The significant innovation of the SAGA lies in its great autonomy. The SAGA has an energy autonomy comparable to a 2000-ton military submarine thanks to its two 75 kW anaerobic Stirling engines and liquid oxygen storage.

Developed by United Stirling and Kockums, the engines operate by combusting fuel with pure oxygen in a pressurized combustion chamber, using a thermodynamic cycle with helium to move the pistons. The combustion gases are expelled into the seawater at different depths through a patented exhaust suppressor.

Conventional diesel-electric submarines operate as follows: On the surface, diesel engines recharge the submarine’s batteries. When submerged, the submarine uses battery power for operations since diesel engines cannot run without oxygen.

In contrast, anaerobic Stirling engines operate in a closed circuit. They do not require oxygen from the submarine’s habitat, allowing for longer submerged periods without needing to surface to recharge the batteries. As a result, with liquid oxygen stored onboard, the submarine can travel 1500 nautical miles underwater to reach the underwater work site, deploy its divers on a week-long mission, and return to its base, all without resurfacing.

2/ Cryogenic Oxygen Storage

As mentioned earlier, the submarine’s autonomy depends on the amount of onboard oxygen. In the SAGA, oxygen was stored in liquid form. One cubic meter of liquid oxygen provides approximately 845 liters of gaseous oxygen, which is twice as much as high-pressure storage of the same volume. The submarine has two external storage units, each holding 3 cubic meters and capable of carrying 6500 kg of oxygen. An evaporator converts the liquid oxygen into gas.

Daniel explains:

“Using liquid oxygen to power the engines was a first for a submarine. Now, there are Swedish submarines with engines powered by liquid oxygen.”

3/ Composite High-Pressure Gas Tanks

The submarine featured high-pressure (400 bar) composite tanks. These tanks, made of a steel body reinforced with Kevlar Epoxy fibers, double the mechanical strength with only a 15% increase in weight. They store compressed air, diving gases, and potentially oxygen for the engines.

Daniel recalls:

“The use of composite materials, especially Kevlar, is another innovative aspect of the SAGA. At that time, this material was not yet used in the underwater environment. It was a significant advancement in terms of strength and durability.”

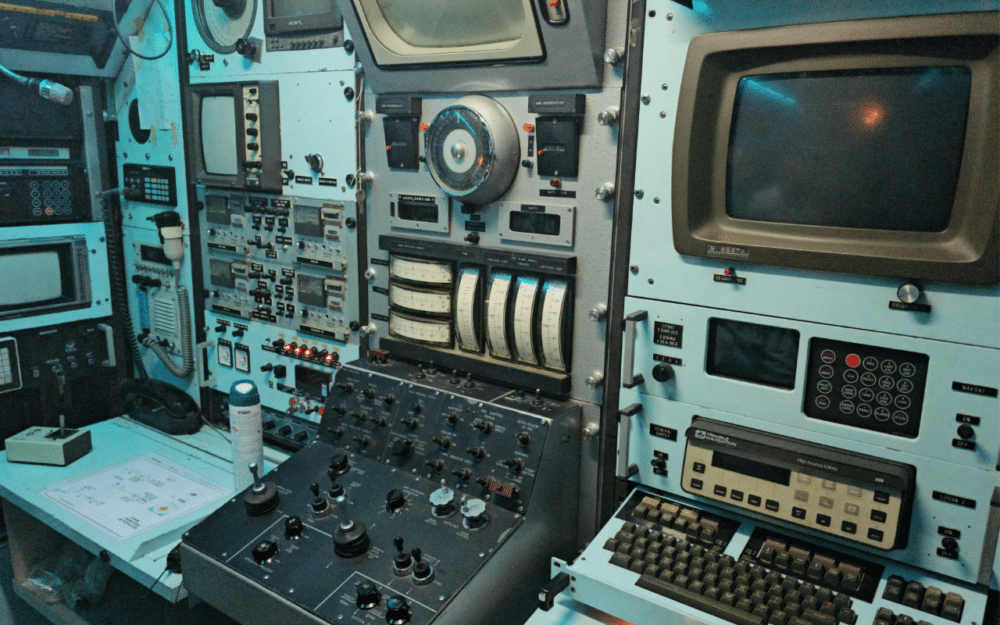

4/ Computer-Assisted Control

The control and piloting functions of the SAGA were largely automated to allow for single-person operation. This was crucial given the small crew size.

Interior Tour

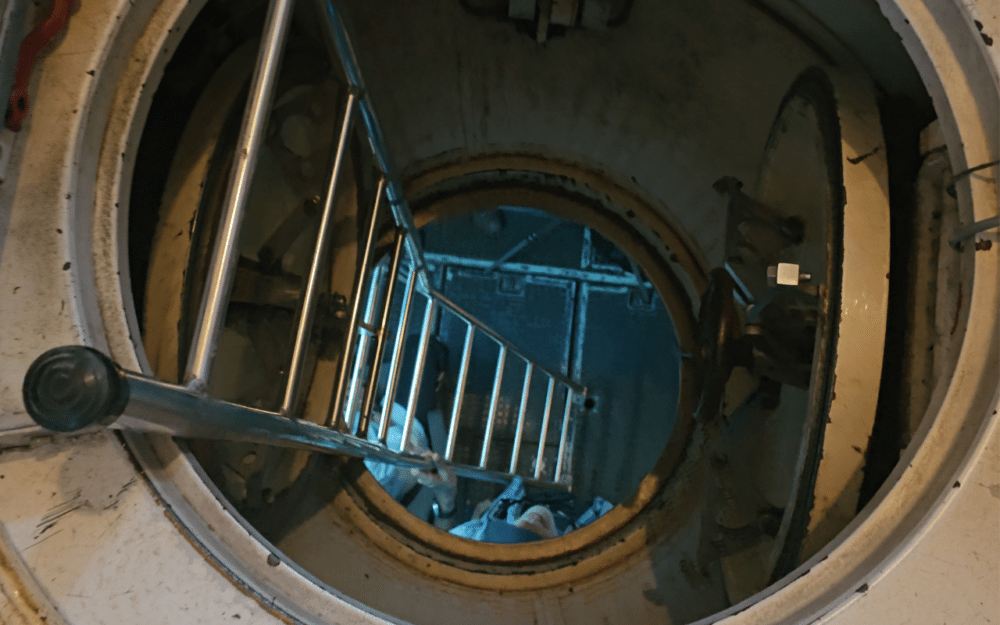

We follow Philippe Mura, a former diver, inside the submarine. We start with the survival capsule on the roof, designed to evacuate the six crew members in case of an emergency.

“The SAGA submarine was designed to operate in hazardous environments, especially on oil fields. In these areas, there are always standby ships for rapid rescue interventions. The survivors would never have had to wait days for help.”

However, the capsule, containing communication systems, rescue equipment, and enough food and drink for three days, was never used.

Navigation Station

We descend via a ladder into the submarine. The first stop is the control room. 600 sensors continuously monitored all vital parameters. Philippe explains that the computer systems of that time, which took up an entire room, are now comparable in capacity to an iPhone.

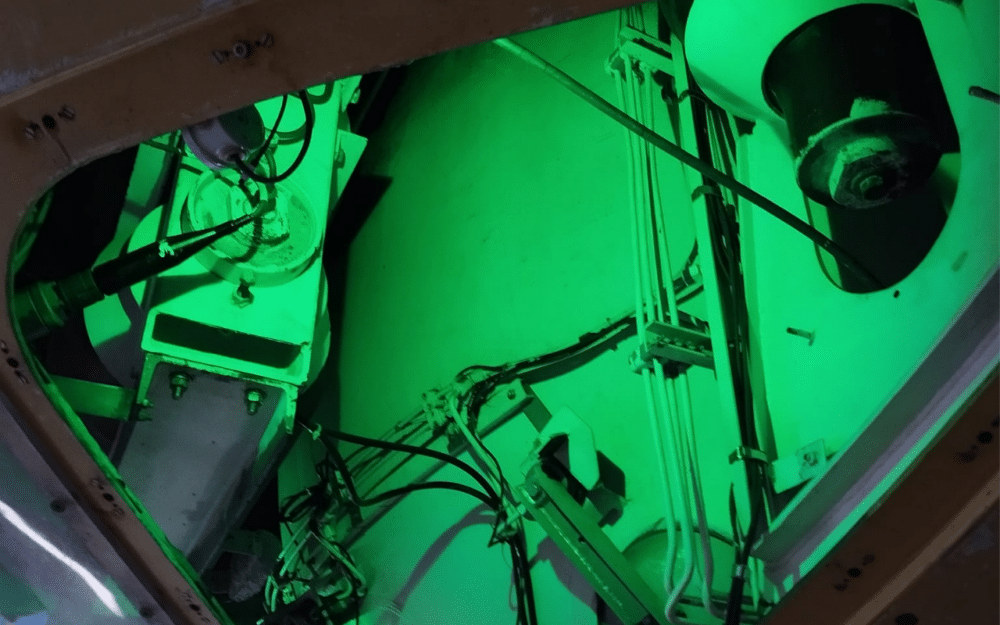

The pilot could steer the submarine using two cameras and an inertial navigation system that precisely located the position of the vessel.

At the front of the vessel, we enter the piloting bay. This is where the commander, lying down in front of a porthole, used a joystick and sonar information to position the submarine on the seabed. Daniel details:

“He positioned the front jack and knew that 15 meters behind, there was another jack to be placed.”

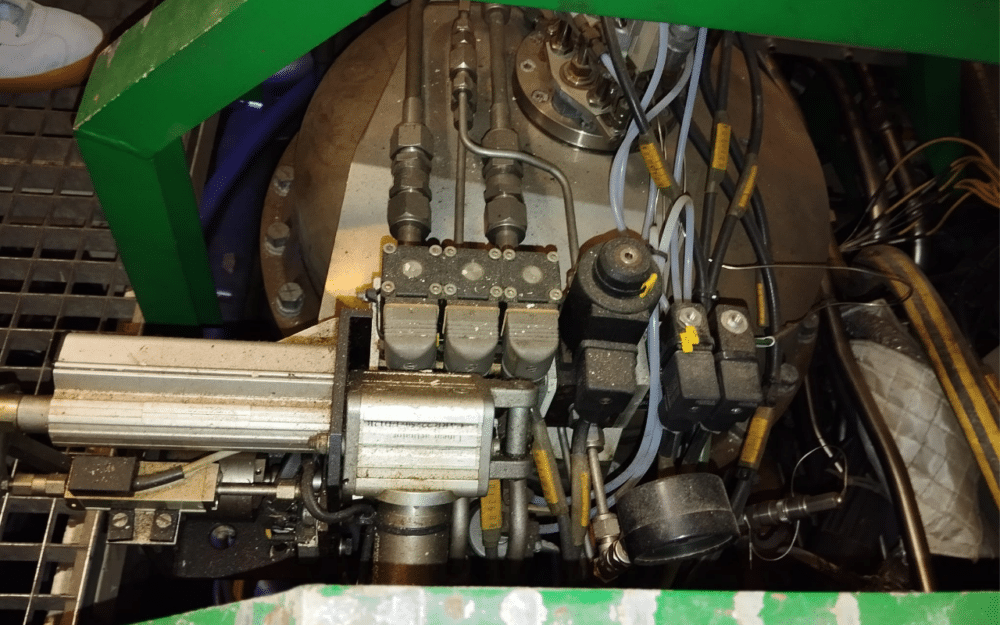

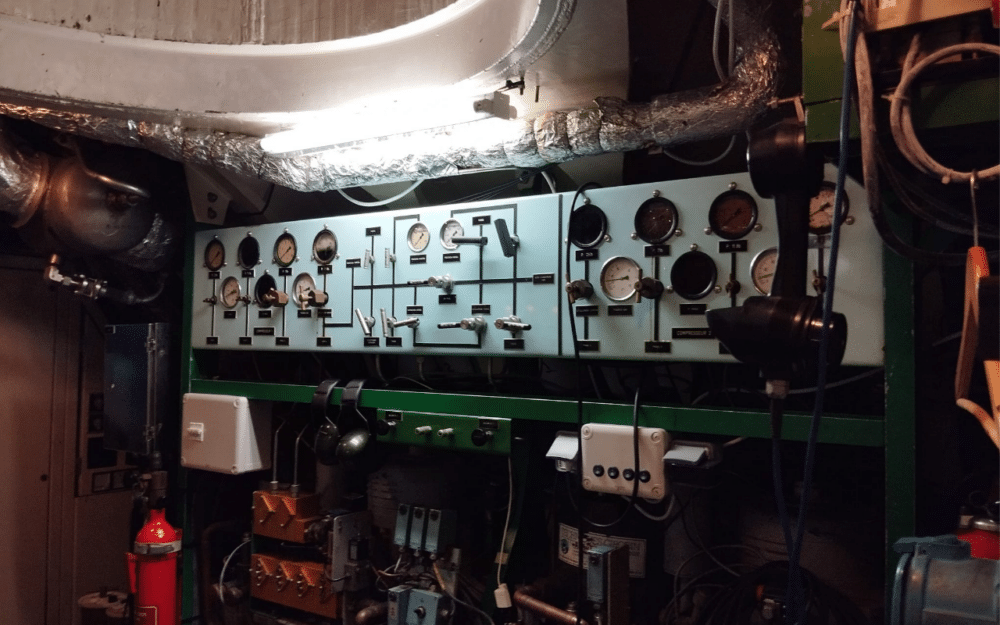

Engine Room

In the engine room, we spot the two Stirling engines, both encased on the floor. Philippe shares that before integrating all the equipment into the submarine, a full-scale wooden model was built. This was to ensure that all equipment, including the engines, fit through the submarine’s hatch. Various tradespeople, welders, and electricians then manufactured the components on-site.

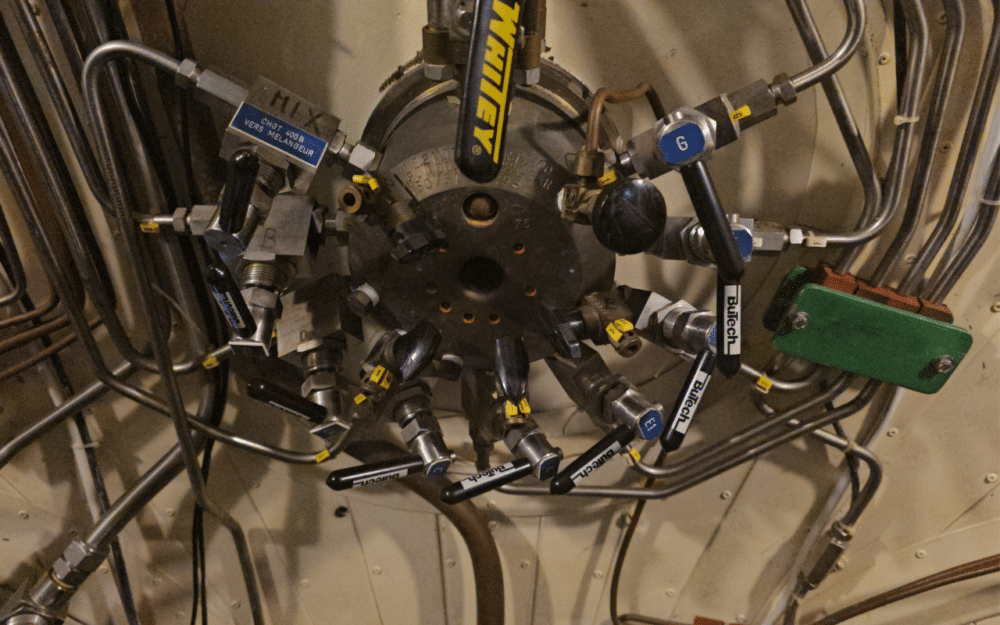

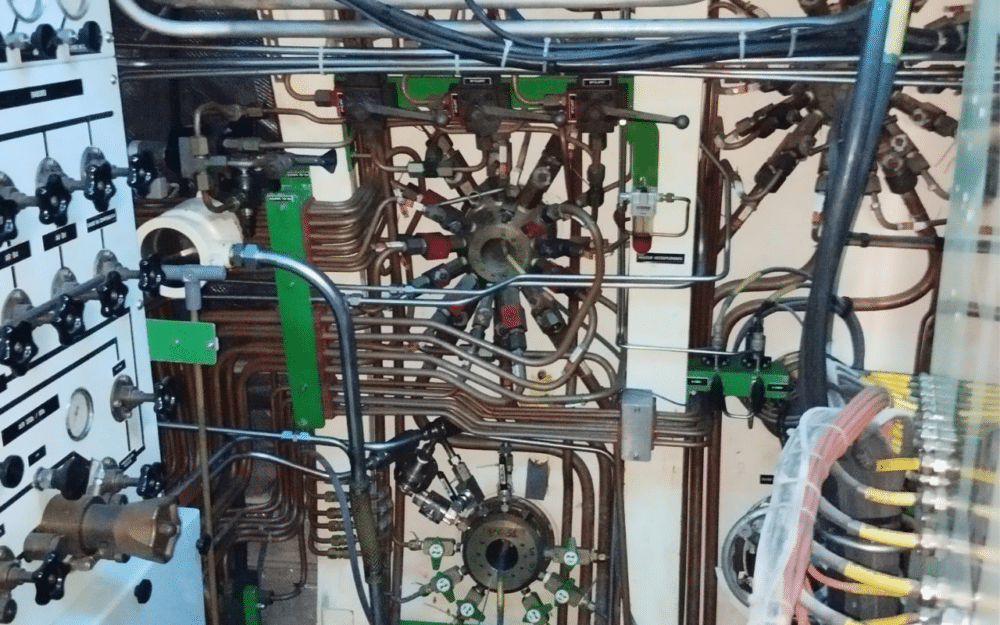

Philippe points out one of these handmade components: the hull penetrations. Their star-shaped copper design immediately evokes the Steampunk aesthetic of the Nautilus, the futuristic submarine imagined by Jules Verne in Twenty Thousand Leagues Under the Sea. Often called “mushrooms,” hull penetrations are openings on the submarine’s pressure hull. Daniel worked on these mushrooms.

“These passages are essential for allowing the passage of fluids, signals, gases, or hydraulic systems through the hull. The fluids or signals enter through these passages, circulate inside the submarine, and exit to control various functions.”

Dive Control Station

Through another hatch, we enter the diver area. Here, the divers are pressurized to the working depth. A master chamber manages all diving parameters, prepares the necessary gases for the depths, handles compression, monitors dives, and manages decompression.

The station integrates decoding systems to facilitate communication, as the divers’ voices were distorted by the helium-based mixture they breathed. There is also a nanometer, systems for winches, and the deployment of the umbilical, which provides breathing gas, hot water, communications, video signal, and lighting to the divers when they are outside. A precise system ensures that the diver does not ascend or descend incorrectly, which could disrupt the decompression phase.

Hyperbaric Chamber

The hyperbaric chamber could accommodate six divers. It was pressurized from the inside out and reinforced with isothermal and thermal protective coating.

This is where the divers live during their mission and where they must wait for several weeks after their mission to adhere to the decompression stages. These stages depend on the time spent underwater and the depth reached. At the end of their mission, the divers are slowly brought back to normal pressure at a rate of twenty-five meters per day. It typically takes 12 days for divers who worked at a depth of 350 meters to return to the surface.

Reasons for Abandonment

In 1991, COMEX’s sales team began pitching to their target clients in the oil industry. However, three years had passed since the project’s resumption and the proof-of-concept stage. During this time, oil companies had developed offshore platforms and imagined ROVs (Remotely Operated Vehicles) for underwater maintenance missions. These ROVs could tighten and loosen valves and reach great depths without needing decompression stops. Ultimately, the industry no longer needed submarines with divers.

Another factor that indirectly affected the SAGA was the Gulf War, which led to a decrease in investments from oil companies.

Additionally, the submarine was based in Marseille, but the more promising work opportunities in the oil sector were in the North Sea, particularly in Stavanger (Norway) and Aberdeen (Scotland). In those areas, the projects became increasingly deeper and required less personnel.

After only 18 dives, the SAGA surfaced. For Michel Bourhis, the SAGA’s journey started too early with Cousteau and was resumed too late by COMEX.

COMEX was acquired in 1992, and the SAGA never returned underwater. It has been stationed in a hangar in L’Estaque since then.

Technological and Heritage Legacy

Although the SAGA did not achieve the commercial success that was anticipated, its innovative technologies for the time have left a mark on the industry. The Stirling engines, for example, still generate significant interest today, as Marcel Bourhis explains:

“These engines have been integrated into various attack submarines, notably in Japan. Recently, Iran also launched three submarines equipped with Stirling engines. The main advantage of the Stirling engine lies in its excellent energy efficiency, making it viable for missions on Mars or the Moon. In the United States, Stirling engines are also used in energy farms.”

Michel, Daniel, Philippe, and others, now retired, maintain the memory of this Marseille submarine. The association they founded in 2014, Les Compagnons du SAGA, aims to preserve this maritime and underwater heritage. They regularly organize visits to the vessel in L’Estaque upon request, to raise awareness among young people and future engineers.