Constant shock input and vibration that occur during industrial automation applications can lead to serious wear and tear on equipment. It can also shorten service life, increase the frequency of maintenance, and jeopardize operator safety. Enidine-engineered energy absorption and vibration isolation solutions prevent expensive equipment downtime. They improve the overall quality of output while minimizing safety concerns for operators.

Content provided by Enidine

Trusted worldwide by global industrial, aerospace, defense, and infrastructure markets, Enidine’s products are designed to endure a wide range of harsh environments and deliver reliable energy absorption, vibration isolation, and noise attenuation solutions.

For highly unique applications, Enidine offers custom shock absorber sizing through its Enisize tool. Customers can select multiple products and models to include in their designs. Through expert engineering, state-of-the-art manufacturing, on-time delivery, and unsurpassed customer service, we solve our customers’ most challenging shock and vibration needs while improving equipment throughput.

Our Products

Here are just a few Enidine energy absorption and vibration isolation products that help deliver better outcomes for our customers:

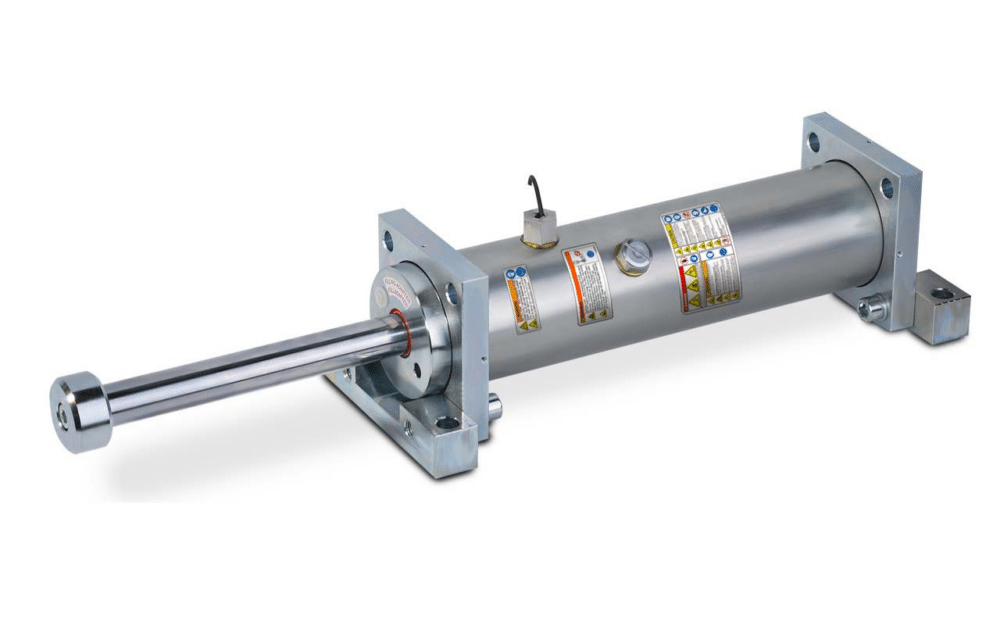

Corrosion Resistant Series (CRS) Shock Absorbers

These shock absorbers are engineered to stand up to the harshest environments. They feature an environmentally friendly design that’s ready to tackle today’s most challenging applications. The shock absorbers can accommodate a wide range of operating conditions with varying masses or propelling forces. They cover a variety of application parameters.

Platinum Extended Range Series (PXR) Shock Absorbers

The small bore non-adjustable hydraulic shock absorbers can accommodate a large array of energy input conditions from various applications. This newly expanded line of tamperproof industrial small shock absorbers provides consistent performance, cycle after cycle, year after year. Also, these models are designed to absorb maximum energy within a compact envelope size while providing you with stable performance over the life of the product.

Heavy-Duty (HD/HDN) Series Large Shocks

They protect equipment from large impacts in applications such as automated storage and retrieval systems (ASRS) as well as overhead bridges and trolley cranes. They are available in a wide variety of stroke lengths and damping characteristics to increase equipment life and meet stringent deceleration and safety requirements.

Wire Rope Isolators

They control damaging shock, vibration, and noise within machinery and equipment. Constructed with stainless steel cable and aluminum retaining bars, Enidine wire-rope isolators are corrosion-resistant and completely unaffected by oil, chemicals, abrasives, ozone or temperature extremes.

Interested in seeing what a partnership with Enidine can do for your organization? Come visit us at IMTS, East Building, Booth #135768. For more information, visit www.enidine.com.

RELATED ARTICLE

About ITT

ITT is a diversified leading manufacturer of highly engineered critical components and customized technology solutions for the transportation, industrial, and energy markets. The company partners with its customers to deliver enduring solutions to the key industries that underpin our modern way of life.

ITT is headquartered in Stamford, Connecticut, with employees in more than 35 countries and sales in approximately 125 countries. For more information, visit www.itt.com.

About ITT’s Connect and Control Technologies Business

ITT’s Connect and Control Technologies business designs and manufactures harsh-environment connectors and critical energy absorption, motion, flow and environmental control components.

Through leading brands such as Aerospace Controls, BIW Connector Systems, Cannon, Compact, Enidine, Neo-Dyn, Conoflow, Micro-mode and Veam, the business serves customers in the aerospace, automation, defense, energy, industrial, infrastructure and transportation markets.