Energy absorption is crucial to the machine tool industry. Shock absorbers are there to allow precise machining. Thousands of them can be found in machining centers.

Shock absorbers are crucial to machining processes. These products are there to prevent shocks and impacts during operations and therefore ensure precise machining.

Every machining center is equipped with shock absorbers, whether it is a metal cutting machine or a milling machine.

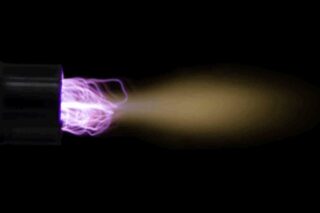

American company Enidine is an expert in energy absorption. Their products are used in machine tools to absorb energy, isolate vibration and attenuate noise.

At IMTS, the International Manufacturing Show that took place in Chicago last month, they showcased their newest PXR series. This is a new range of hydraulic shock absorbers that are expected to absorb more energy than previous versions.

Watch our video interview from IMTS

According to Rob Marshick, Sales Manager at Enidine,

“This new series of shock absorbers has a roHS compliant nickel plated coating which is excellent for durability and energy absorption.

Basically, what happens is that when there’s an impact, if it’s the equipment or the machine, we are forcing the oil through a number of ware fuses to slow down the load and minimize the impact. We never get rid of energy, we just transform it into thermal energy. So it will be dissipated through the body of the shock. The other big feature with our new products is that they have a larger button on it which handles a lot more energy than our competition. ”

Different sizes of shocks are available depending on the applications.

New Trends for Shock Absorbers

Currently, various trends in the machine tool industry impact the shock absorbers sector.

“I believe we are seeing speed. People want things quicker, they want products done quicker. So that pushes the machine tooling industry to manufacture faster. And that really is what we do. As the components in the equipment move quicker, they need some help with the vibrations, or the impacts and that’s exactly what we do.”

Machine tools are also becoming more intelligent. They can now communicate with the operators and even predict future failures. Shock absorbers could also have, in the near future, predictive maintenance capabilities.

“We are actually working on that. We are not ready to talk about it now. But this is definitely something we have been following for a few years. Predictive maintenance is one of the things our customers want. And the question is: can we provide this at a cost that they are willing to pay? So far, everybody has been open to the idea.”

Will machine tools companies be willing to pay for such new shock absorbers? It is not that sure for the moment.

![[IMTS 2022] The Importance of Shock Absorbers for Machine Tools](/wp-content/uploads/sites/3/Enidine-shock-absorbers-1250x807.jpg)