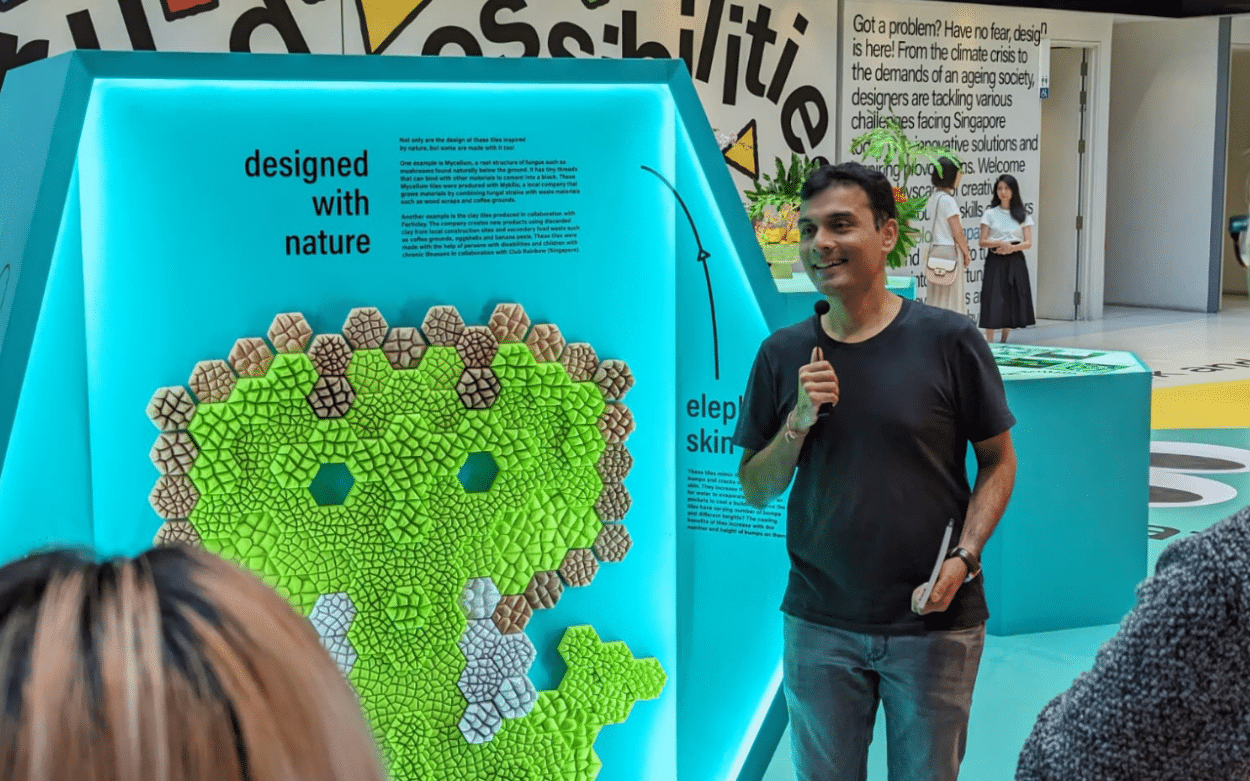

What if we drew inspiration from what works in nature to enhance our lives? What if animals provided us with concrete and effective examples, such as constructing energy-efficient buildings? The concept of drawing inspiration from nature is called biomimicry, and the Singapore-based company bioSEA has made it its focus. bioSEA is working on tiles inspired by the skin of elephants and has already produced successful prototypes tailored for Singapore’s tropical climate. Anuj Jain, Director and Principal Ecologist at bioSEA shares more about biomimicry and how he believes it can help us build better buildings for the future.

Can you explain what biomimicry is and how bioSEA was born?

Anuj Jain: “bioSEA is an ecology and environmental design consultancy that was established in 2017. Our primary goal is to integrate nature as a stakeholder in the built environment. There are two key aspects to our work: ecology and biomimicry.

My educational background is diverse—I initially studied engineering for my first degree and later delved into biomimicry and ecology. Several years ago, I started exploring biomimicry and the idea of restoration programs worldwide aimed at restoring habitats. To me, this represents biomimicry at the landscape level, where we learn from nature to restore what we once were. Restoration involves emulating nature. Taking this perspective, I began thinking about how we could apply nature-inspired design not just in terms of incorporating green elements but throughout the entire design process for buildings. That’s how the concept originated.

I had been thinking about this project for some time, and it wasn’t until 2021 that we were able to gather resources. Thanks to a grant from the Design Singapore Council we were finally able to assemble a team.”

You have designed elephant skin-like tiles. At which stage or level of advancement are they currently?

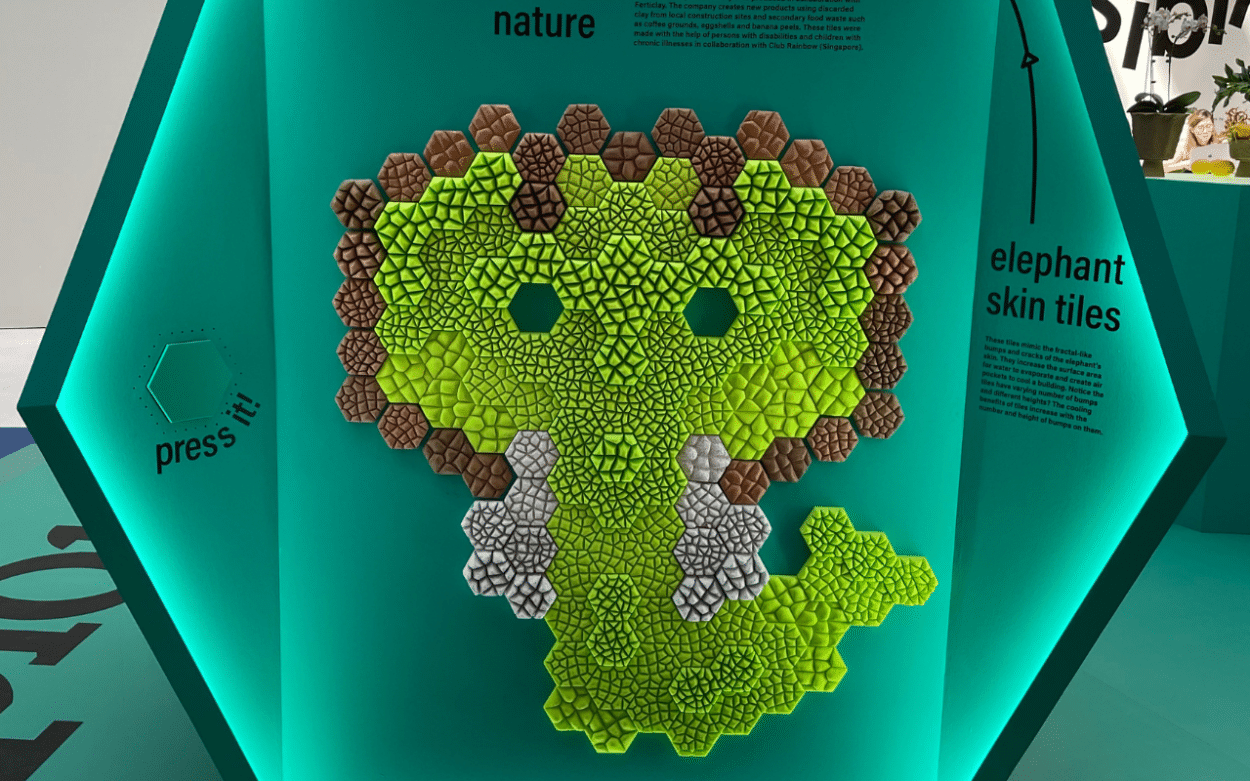

Anuj Jain: “So, we’ve completed the design phase, developing various algorithms that resulted not in a single design but multiple patterns. What we’ve essentially created is a methodology that involves examining elephant skin patterns, understanding their scale, and determining the underlying principles. Depending on factors such as the angle of the sun and other parameters, we can curate a design that maximizes efficiency. In an ideal future scenario with more additive manufacturing and AI technology, each building tile could be uniquely different, similar to the diversity of human and elephant skin.

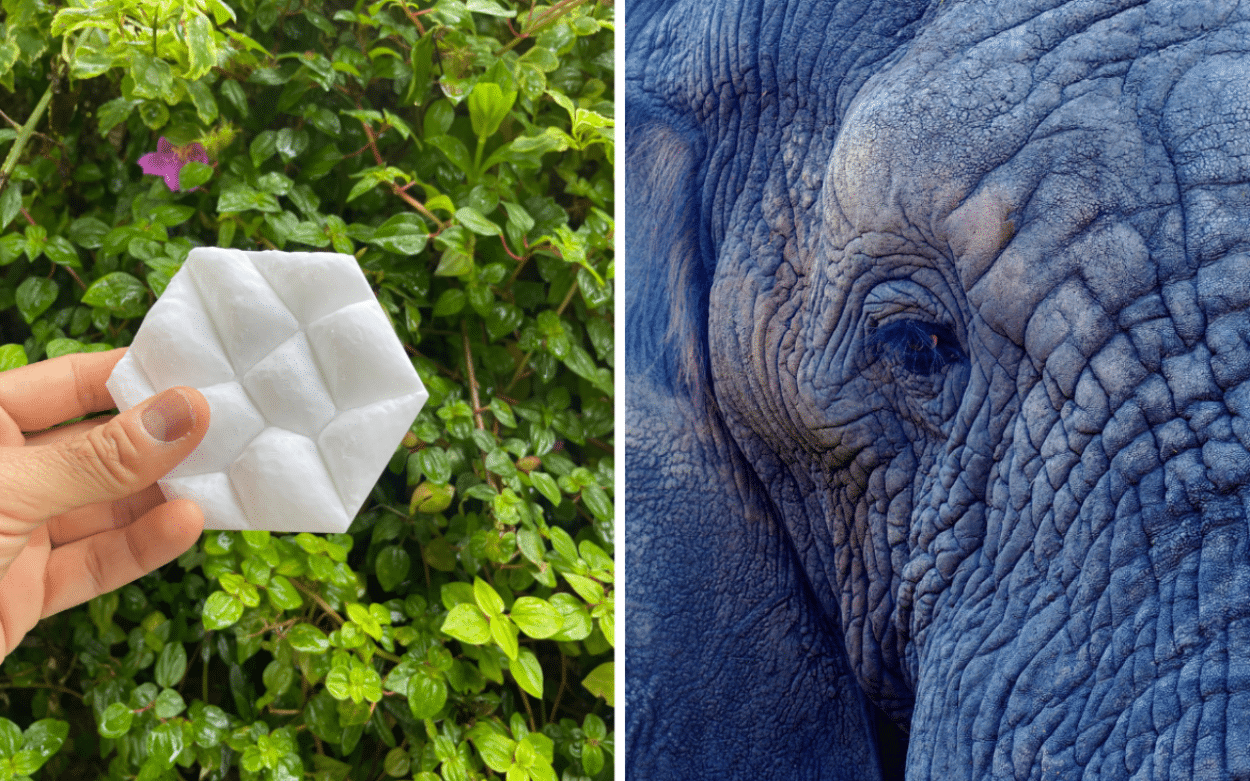

We’ve produced prototypes using materials like cement, concrete, clay, mycelium, and 3D-printed biodegradable plastics (PLA). Performance testing across different patterns has been documented, and we’ve secured design registration through Singapore’s Intellectual Property Office. Our research and prototyping efforts have been detailed in publications.

Currently, we’re in the phase of collecting field data and building application data. There’s an ongoing prototype in Singapore, focusing on its hot and humid climate. Discussions are also underway for another prototype in a dry and arid climate to demonstrate the approach’s benefits. We’re exploring opportunities to apply this technology to projects, with potential applications in Rajasthan, India, known for its dry climate.”

Are the tiles designed to be crafted from recycled materials?

Anuj Jain: “We’ve experimented with discarded clay sourced from construction sites, which typically results from excavation activities. This excess clay, along with other waste products such as food waste, coffee grounds, and banana peels, is repurposed. We collaborated with a local designer to refine this mixture. For mycelium, sustainability is achieved by using a local fungal strain combined with sawdust and other substrate materials, with the sawdust being a byproduct of the furniture industry.

The objective is to ensure sustainability for both mycelium and clay. As for concrete, we are in the process of exploration. Recycled concrete is available, and we are working on blending it with other sustainable materials to optimize its ecological impact.”

I read that the efficiency of the tiles decreases energy use by 20%. Can you confirm? Additionally, how does it impact temperature?

Anuj Jain: “Correct. The extent of temperature reduction depends on the application and the quantity of tiles used. In some cases, you can achieve a decrease in indoor temperatures by a few degrees.”

Do you mean that the objective is not to install tiles on all facades but to strategically place them where they can achieve maximum efficiency?

Anuj Jain: “Correct. You can consider the sun-facing facade as the one that receives the most sunlight. We’ve developed various designs, resulting in efficiency ranging from approximately 20% to about 70% reduction in heat flux. Heat flux refers to the amount of heat transmitted. Imagine a standard outdoor wall facing the sun, with a room on the inside, like a living room. The reduction in heat varies based on the design complexity. More intricate designs experience a more significant reduction in heat flux. However, the trade-off involves the challenges of cleaning and maintenance due to the added texture, and sometimes, a slightly increased use of materials. So, the balance lies between practical cleanliness, material usage, and performance.”

How do you intend to manufacture the tiles?

Anuj Jain: “So, we have two possible approaches, each with its own set of performance benefits. The first option is a conventional method where we use different molds to create tiles. For a more adaptive and complex solution, we can employ 3D printing. Both approaches are feasible, and the choice may depend on the ease of 3D printing with specific materials. For instance, clay and concrete work for 3D printing, while mycelium 3D printing is not as advanced. The decision also factors in considerations like scale and the desired level of final detail, depending on the material.”

And will those tiles be expensive?

Anuj Jain: “This is a common question, and it’s something we’re actively working on. Currently, the production is somewhat expensive because the designs are created here, and labor costs in Singapore are high. Since we customize them on a small scale, the typical cost for cladding, such as lifestyle, soundproof, or thermal cladding (around one meter by one meter), may range from $50 to $100. Our tiles might approximately double that cost, but it varies, with labor costs being the primary factor. Material costs are relatively lower, so the key is finding ways to scale up and potentially manufacture in a cheaper country.”

Are these tiles intended exclusively for new buildings, or can they also be integrated into existing infrastructure?

Anuj Jain: “I believe they can certainly be applied to existing buildings. The technology is straightforward; it’s like adding a tile, not a complex process. The intricacy lies in each tile. They can be used as an adaptive facade, often referred to as adaptive reuse.”

What feedback have you received from architects, designers, and the infrastructure industry?

Anuj Jain: “Architects are excited about the improvement in both performance and aesthetics. I think the product looks aesthetic, due to its texture. So I think most people like it so far. Discussions are ongoing with architects on the installation process. There’s also been some interest from interior designers to incorporate the product indoors. We plan to test its performance in air-conditioned rooms to assess its impact on cooling efficiency, with the expectation that more data will provide insights into this aspect.”

You are also working on other types of components that mimic nature. Can you provide more information about them?

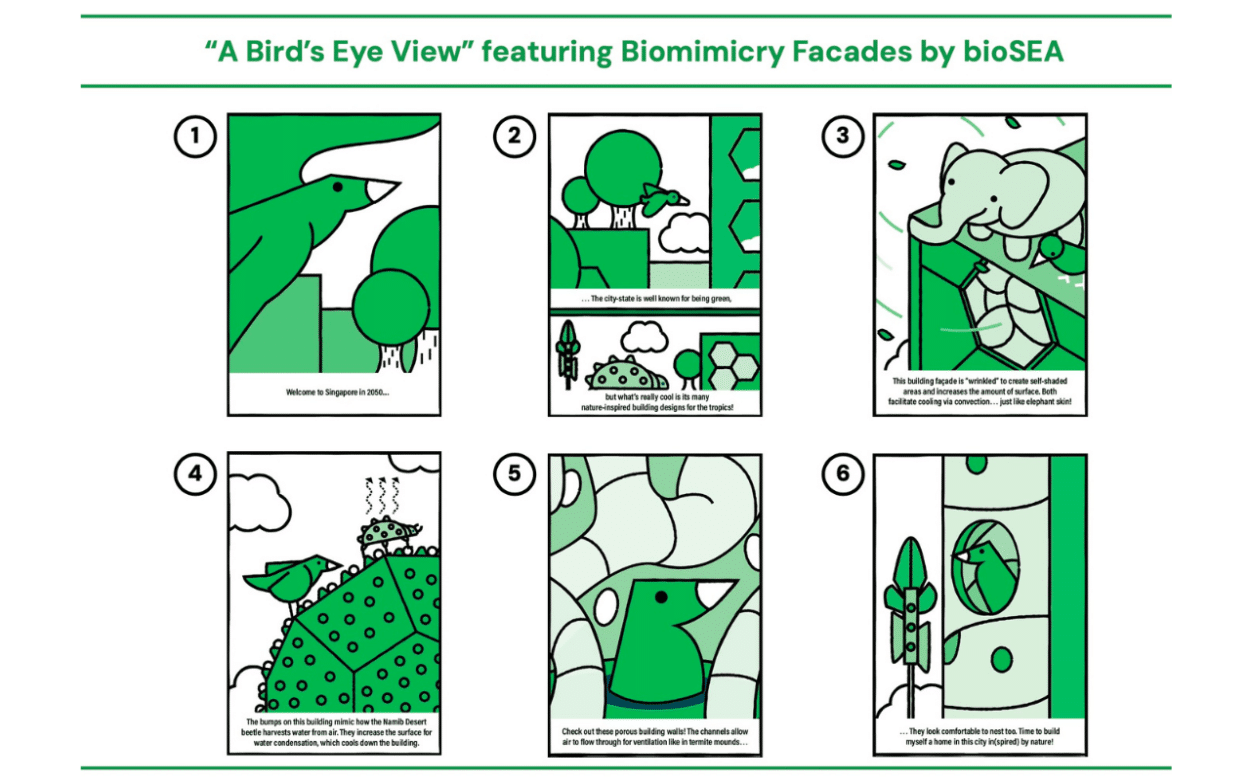

Anuj Jain: “We are indeed also exploring the concepts of termite mounds and of the Namib Desert beetle. Termite mounds focus on ventilation and improving air movement. They are relatively well-known in the architecture industry. You may have heard about buildings such as the East Gate building in Zimbabwe and the council house in Melbourne, Australia. Although these buildings incorporated aspects of termite mound ideas, the understanding of termite mounds at the time of their construction was limited. So not everything could be mimicked. We wanted to go further and enhance airflow within spaces, particularly when wind speeds are low.

When you look at nature, branching structures act as efficient ventilation ducts, resembling lungs, unlike the tubes and pipes prevalent in built environments. Termite mounds operate on similar principles, adapting to different conditions such as wet or dry climates and day or night. They function as complex systems, acting like chimneys that induce a stack effect in buildings. Our approach involves studying the branching within termite mounds and applying the principles to brick structures. We have created modular systems, consisting of five bricks stacked together, each containing internal tubes and branching structures. Unlike traditional brick walls, our design incorporates holes instead of a closed surface, providing a unique approach to ventilation with smaller openings compared to conventional windows.”

What is the development stage of these brick walls?

Anuj Jain: “We have created prototypes and also exhibited them. Through performance testing, we have determined that, in terms of ventilation, our design surpasses traditional methods by approximately 28%. One immediate application could be in a data center because they generate so much heat due to the computers and they need extensive air conditioning. Given that data centers primarily house machines rather than people, integrating ventilation features into the building structure holds significant potential.”

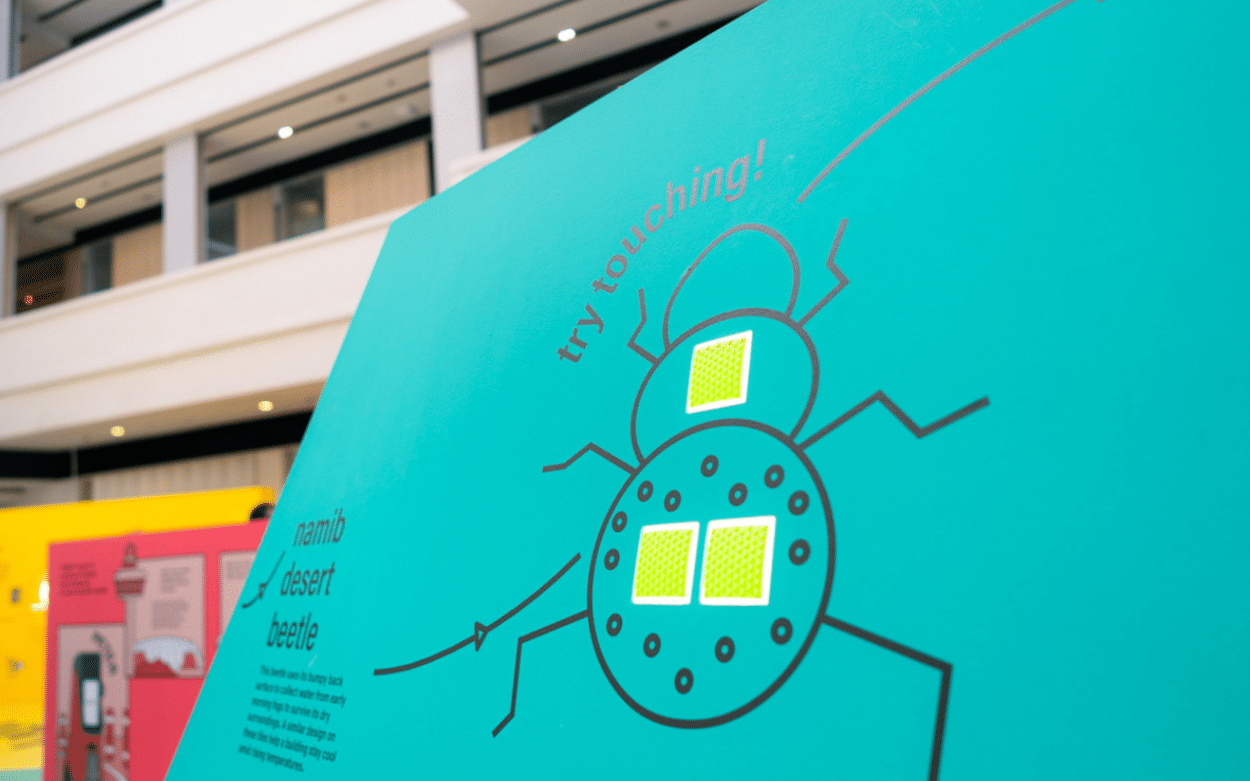

And what about the Namib Desert beetle?

Anuj Jain: “The Namib Desert beetle serves as an excellent model organism for condensing water, particularly due to its habitat in the dry desert near the sea. Although rainfall is scarce in this region, the sea wind carries water through fog and mist, creating a humid environment. To adapt to these conditions, the beetle has developed bumps on its body that aid in water retention. Our study delves into this adaptation, optimizing it for application in buildings by considering factors like density and shape.

We have conducted prototypes tailored for various climates, emphasizing water condensation in arid regions. In humid climates like Singapore, where condensation is less effective due to existing air humidity, our focus shifts to collecting humidity. However, these designs aim to mitigate stormwater issues in urban areas, where increased construction has led to reduced natural spaces. By slowing down water runoff from buildings through these technologies, we contribute to minimizing stormwater-related problems, such as flash floods and runoff, exacerbated by climate change.”

You have recently released a toolkit. Can you give us more information about it and its purpose?

Anuj Jain: “We launched the toolkit last April because we felt that a lot of architects have heard of biomimicry but they don’t know it well enough. Instead of reinventing the wheel, what if we could curate them and really explain when to apply this versus that? And sort of then back it up with our own designs to explain the process of how urban biomimetic design works. It was to disseminate the knowledge of biomimicry design, nature-inspired design, in the built environment in a non-academic way that the industry could understand. Because a lot of knowledge is sort of in journal papers and in universities, but the industry sometimes has a hard time applying it. So, we wanted to bridge that gap. We also curated about 24 different examples from around the world, some could be research, some others built, some are small scale or at the building scale.”