The CHU de Brest enhances surgical preparation through the utilization of advanced Stratasys 3D printing technology, which creates patient-specific anatomic models. J5 MediJet 3D printer’s multi-material, multi-color capabilities enable surgeons to produce realistic models to plan complex surgical procedures, improving planning, training, and patient outcomes.

Content provided by Stratasys

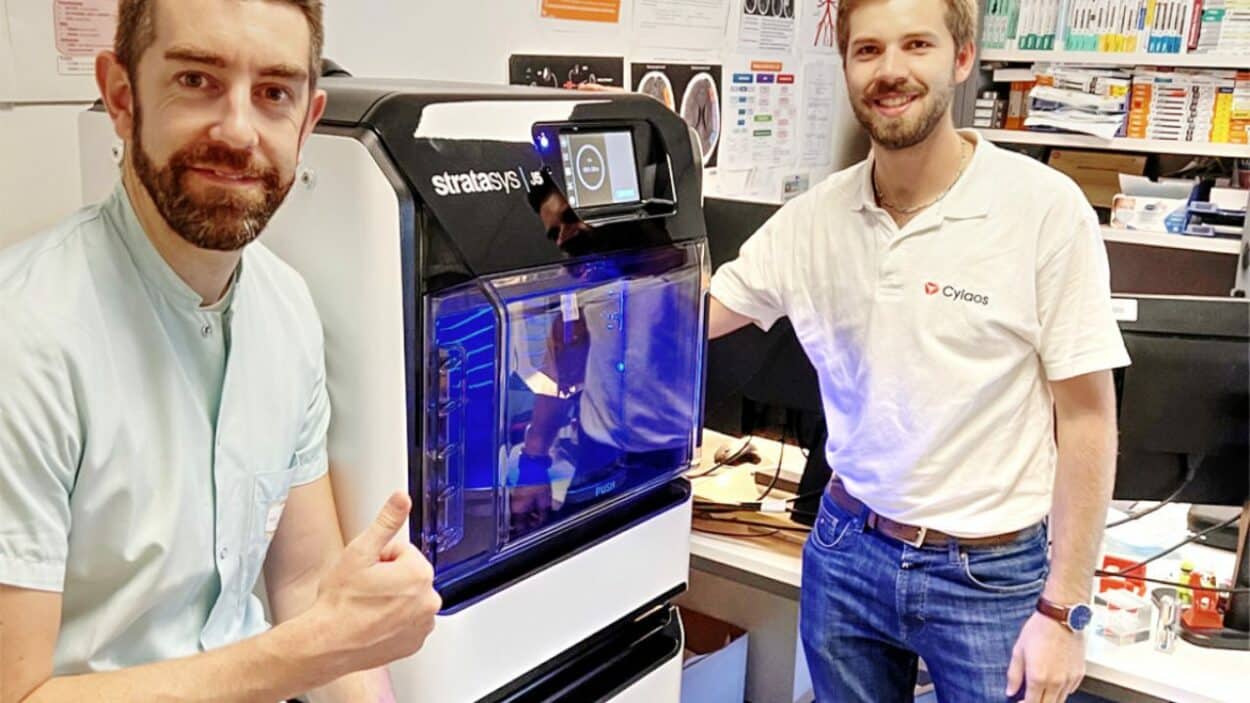

France-based Regional University Hospital of Brest (CHU de Brest) is witnessing substantial improvements in pre-surgical planning procedures following the implementation of a new 3D printer by Stratasys’ partner reseller, Cylaos.

The installation gives surgeons highly accurate and detailed 360-degree patient-specific anatomic models prior to the actual operation, which may improve surgical risks and reduce time in the operating room.

According to Samuel Guigo, radiology and 3D printing technician at the CHU, the realistic sophistication of the 3D printed models produced with the all-in-one, multi-material, multi-color J5 MediJet over previous single-material, single-color options is transformational and sets a new standard for medical modeling.

“The accuracy we now enjoy with the J5 3D printed models means our surgeons are far better equipped and prepared before going into theater, which significantly and quantifiably reduces surgical-related risks through improved safety.”

Guigo adds:

“When preparing a vascular surgery, for example, millimetric precision is mandatory. With the J5 MediJet, not only can we achieve this, but we have the flexibility to re-print the models to iterate and achieve optimal results, reproducing them with complete consistency, as required. We were simply unable to do this previously.”

The use of Stratasys’ advanced 3D printing technology is, explains Guigo, a crucial factor contributing to the quality of the anatomical models the hospital can produce. This, he says, is underscored by the Elastico TM photopolymer material.

“We can produce models on the MediJet with far greater realism than our other 3D printing technologies allow. With the Elastico material, for example, the haptic feeling and surface smoothness replicate the patient’s soft arteries much more closely.”

The shortcomings in the hospital’s existing alternative technologies also meant that the production of some models had to previously be outsourced to external providers. Nevertheless, with a level of quality that fell short of the hospital’s requirements, together with a mounting need to better manage increasing volumes, the acquisition of the in-house J5 MediJet made logical business sense.

Improving Training and Patient Care

Beyond pre-surgical preparation, the use of patient-specific 3D printed medical models produced on the J5 MediJet for on-demand training can improve patient outcomes by reducing complications and decreasing overall recovery time and length of hospital stay.

In addition, with a highly accurate patient-specific 3D printed medical model, surgeons can better explain specific pathologies and procedures to patients prior to surgery, which has been proven to improve a patient’s therapeutic understanding and satisfaction.

“The MediJet means that we’re winning in every area. We have greater management of growth requirements and have addressed quality issues, while also improving processes and educational practices.”

Since its installation, the use of the J5 MediJet has rapidly expanded to different hospital departments, including Interventional neuroradiology, orthopedic surgery, vascular surgery, and neurosurgery, as well as biomedical services.

Looking ahead, the CHU’s next aim is to set up a dedicated 3D printing arm that will address the needs of the hospital’s departments, research team, and training. With the hospital focused on championing the technology’s general use within the medical sector, there is also a vision for producing 3D-printed anatomical models for other hospitals, as well as for biomedical engineering schools.