With its Target Zero Defect, the Dassault Systèmes 3DEXPERIENCE platform is now considered by global automakers to be the best tool for gaining efficiency.

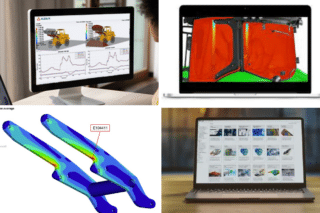

The 3DEXPERIENCE software package includes applications for creating 3D models and virtual-reality presentations, as well as handling real-time design, engineering and manufacturing data. Models can be used from the shop floor to top management. Additional applications allow collaborative connections between internal and external users, from design, marketing and sales to outside suppliers and agencies.

Many of the world’s leading automakers already use this platform—BMW, Porsche, Ford, Chrysler, Fiat and Hyundai. Even electric car innovators Tesla Motors and Faraday Future are among the clients.

Target Zero Defect

This year, Faraday Future introduced the FFZERO1 intelligent electric vehicle, developed with 3DEXPERIENCE.

- The Target Zero Defect solution fosters results that are right the first time. Its data repository supports predictions of budget and development cycles, ensuring accuracy and saving time and money.

- The Smart, Safe & Connected function offers an integrated environment for testing and validating mechanical, electronic and software vehicle systems.

Virtual-reality design shaved months off the traditional process of creating a physical model of the car and sitting in it to optimize function and ergonomics. According to the company, the platform could enable the creation of an entirely new interior in a single day.

Jaguar Land Rover also has employed the 3DEXPERIENCE platform in its business transformation program to attain much higher annual efficiency gains than the industry’s traditional goal of 4%.

Paul Davies, director of the company’s product development operation, reported that after one year, the benefits were approximately “three times what we originally planned.”

Over a full three- or four-year program life, he expects to see engineering productivity gains of over 20% and time savings of up to 40% for certain product development processes.

Vehicle Program Intelligence

The latest development on the 3DEXPERIENCE platform was announced last June—Vehicle Program Intelligence. This incorporates tighter integration of Dassault’s EXALEAD PLM Analytics product for more complex modeling and real-time data analytics to improve project management. Its richer engineering data set enhances decision-making and reveals dead ends more quickly. It also facilitates corrective action, accelerates time-to-market and provides a single view for all users. One key aspect is improved EXALEAD dashboards to present key performance indicators that can index and access billions of records of any type for better data aggregation.