The oil and gas industry is going digital. These words opened the Bentley Year in Infrastructure in Singapore this October. As invitees, we were able to meet with Anne-Marie Walters, global marketing director and Phil Christensen, VP of modeling at Bentley Systems. They shared their insights on how digital modeling will impact the sector.

DirectIndustry e-magazine: Why is oil and gas now going digital?

Anne-Marie Walters: A lot of owners wanted to go digital to save time and money. Over 65% of projects in the oil and gas industry were coming in late or over budget. More important, they were failing to deliver plants that met requirements. Last year, the owners decided to act, especially since lower oil prices were driving them to be more efficient. They realized the industry has an interest in digital engineering models of their construction projects for more transparency. For example, digital models can enable predictive maintenance and other operational improvements.

DirectIndustry e-magazine: Does that mean the sector is betting on increasing efficiency by going digital?

Anne-Marie Walters: It’s all about driving down costs and improving efficiency. Complete information is also important. For example, the industry uses pumps extensively. With sensors everywhere and the industrial Internet of Things, you can measure when a piece of equipment is vibrating too much or overheating. Until now, data wasn’t being turned into actionable information. Going digital means using the information you have for better asset management.

DirectIndustry e-magazine: Can you quantify the advantages of digital simulation for the sector?

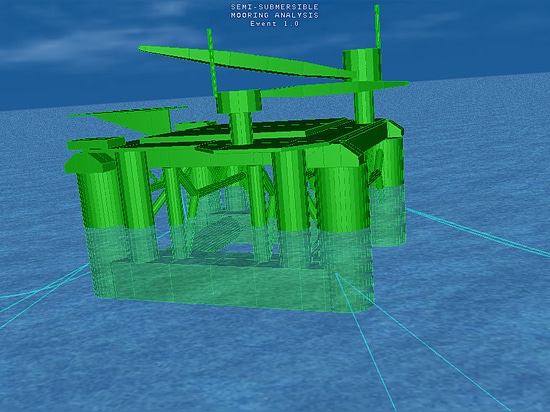

Phil Christensen: The owners are optimizing the amount of time needed for installation because offshore time is very expensive. With digital models, they can save days of installation time. One day of installation costs $100,000 or more for these offshore vessels.

DirectIndustry e-magazine: How will digital simulation affect the way we build installations?

Phil Christensen: The big change is going to be in life extension. A big sector challenge is aging assets. Particularly with low oil prices, there won’t be a lot of new projects. The question is, How do I get more out of my existing assets? We’re already seeing drones inspecting platforms so we can assess their condition and decide what to do to extend their life. Drones soon will be installed on every platform and operated remotely. This is going to have a big payoff. And having a 3D model to better inform decision making is much better than just having photos.

DirectIndustry e-magazine: A lot of projects presented here in Singapore are Chinese and Indian. Why?

Anne-Marie Walters: In developing markets, including China and India, there’s been heavy reliance on manual work and paper documentation. They’ve begun to realize that they can streamline their projects. They’re driven to do things faster, to build infrastructure quickly to meet the needs of changing societies. They went from 2D, paper-based processes directly to advanced 3D. They’ve come up with optimum 3D designs for pumped storage hydropower plants to reduce the cost of delivery.