From steering systems to electric motors, Smalley Spirolox® Retaining Rings have been the trusted solution in the Automotive industry for over 100 years because of their unique configuration, reliability, and ease of use. This article explores the differences between a traditional stamped circlip (snap ring) and a Smalley Spirolox Retaining Ring.

By Justyna Rapacz, Marketing Engineer at Smalley

Spirolox® Retaining Ring Advantages

01. Spirolox Retaining Rings are coiled, not stamped, providing greater design flexibility.

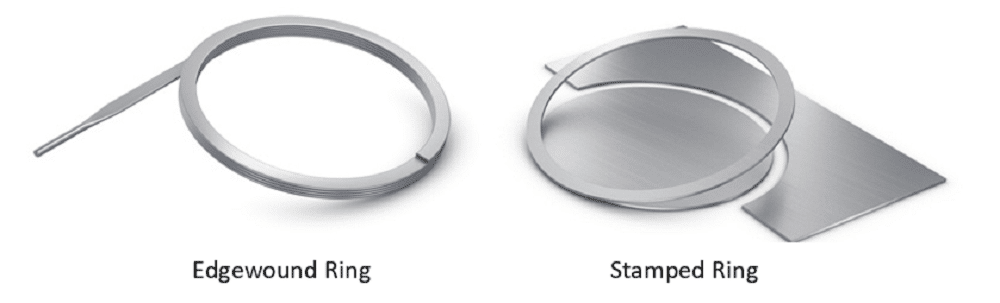

All SpiroloxRetaining Rings are coiled using our unique Edgewinding process. Edgewinding has been our trusted manufacturing process for over 50 years, providing precise yet flexible solutions to meet your retaining ring needs. Round wire is first processed through our in-house rolling mill to a flat state. Then it is coiled on edge to form the ring. Edgewinding provides us the flexibility to have 6,000 standard parts broken up into 30 configurations.

Coiling our rings does not require dedicated punch and die tooling, which are necessary for traditional stamped circlip manufacturing. This flexibility to modify part diameters without tooling replacement allows for improved confidence that our Smalley engineers can tailor a ring to meet even the most stringent application constraints.

What this means for you is quick, easy, and economical customization at any stage of the development process. If one of our standard rings does not meet your application requirements, a custom ring can be made with No-Tooling-Costs™.

Additionally, only the required flat wire material is coiled during edgewinding, which virtually eliminates all material waste. When a stamped retaining or snap ring is made, it is stamped from a piece of metal sheet, which in turn creates scrap from both inside and outside of the ring. In cases where a large diameter or an exotic material is required, the scrap cost increases drastically.

02. No Ears to Interfere® with undesired components

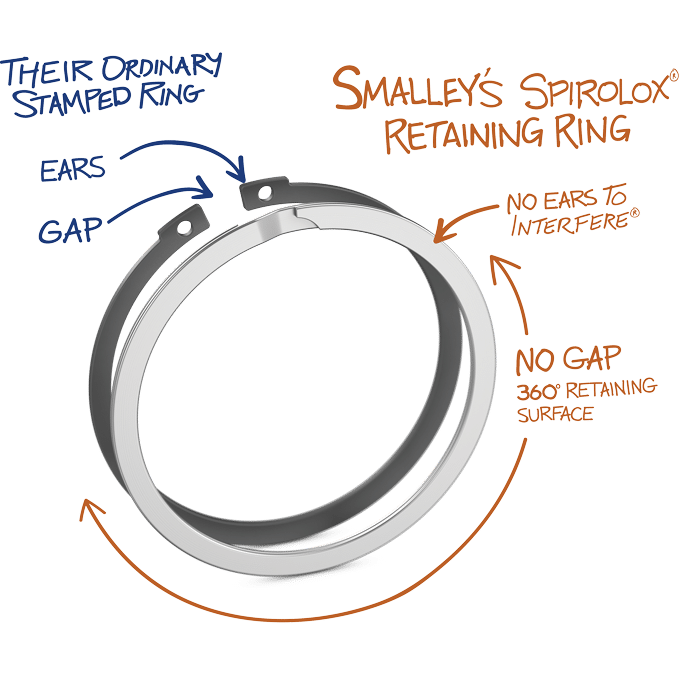

Due to the edgewinding process, the Spirolox retaining ring’s main advantage is in its unique configuration. Traditional circlips have “ears”, also referred to as lugs. The ears take up additional radial space, which may cause an undesired interference with other components. Spirolox rings have No Ears to Interfere®, smoothly integrating into your assembly to retain mating components while maintaining a low radial profile.

03. Improved Aesthetic Appearance

Besides providing a functional retaining surface, Spirolox rings are often preferred for their improved aesthetic appearance. In applications where the ring is visible, a Spirolox ring blends into the assembly since it has no protruding ears. A number of coatings, finishes, and materials are available to meet aesthetic requirements.

04. 360° Retaining Surface

Unlike traditional circlips, Spirolox Multiple-Turn rings have a uniform cross-section and no gap. Having a 360° retaining surface, Multiple-Turn Spirolox retaining rings provide even load distribution to securely hold mating components in place.

05. Groove Interchangeable

Not only do Spirolox rings meet various quality of part requirements, but they’re also groove interchangeable with stamped circlips. What this means is that a Spirolox retaining ring will fit in the same groove and retain the same load as its corresponding circlip. If you’re currently using a circlip, check out our Interchange Listing Table to see what Spirolox part can replace it, all without any design changes.

06. Safe and Easy Installation and Removal

Spirolox retaining rings are safer and easier to install and remove in comparison to snap rings. The typical installation process for circlips involves snap ring pliers. Snap ring pliers are inserted into the ears of the circlip, and the ring is then stretched over a shaft or compressed into a housing. During installation and removal of a larger sized circlip, the risk of the ring flying off the pliers poses a safety hazard.

In contrast, Spirolox rings can be installed by spiraling the ring into the groove by hand. This gives the operator more control of the ring, posing less of a safety risk. They also come standard with a removal notch for simple removal requiring no special tools. Any flat-blade tool, such as a screwdriver or staple remover, can be used to spiral the ring up and out of the groove.

To learn more, watch our Installation and Removal Videos.

Get Started

Request FREE Samples from over 6,000 of our standard retaining rings stocked in carbon and stainless steel, or work with our team of engineers to customize a ring to your requirements.