Water treatment specialist Best Water Technology (BWT) France has launched a new water disinfection solution that removes the need for chemicals and reduces harmful by-products in manufacturing waste.

Having a solid waste management system is crucial to industrialists. It is indeed a high-level tool for the control of the impacts of an activity on the environment.

How do they take care of waste products? How do they manage water contamination? How do they clean and disinfect wastewater? These are some of the questions that they have to ask themselves. Usually, their answer is to resort to chemical disinfection.

New Chemical-Free Water Treatment Solution

But using chemicals for waste disposal is not without effect on the environment and industrialists are increasingly taking this risk in consideration. This is why new chemical-free solutions are emerging.

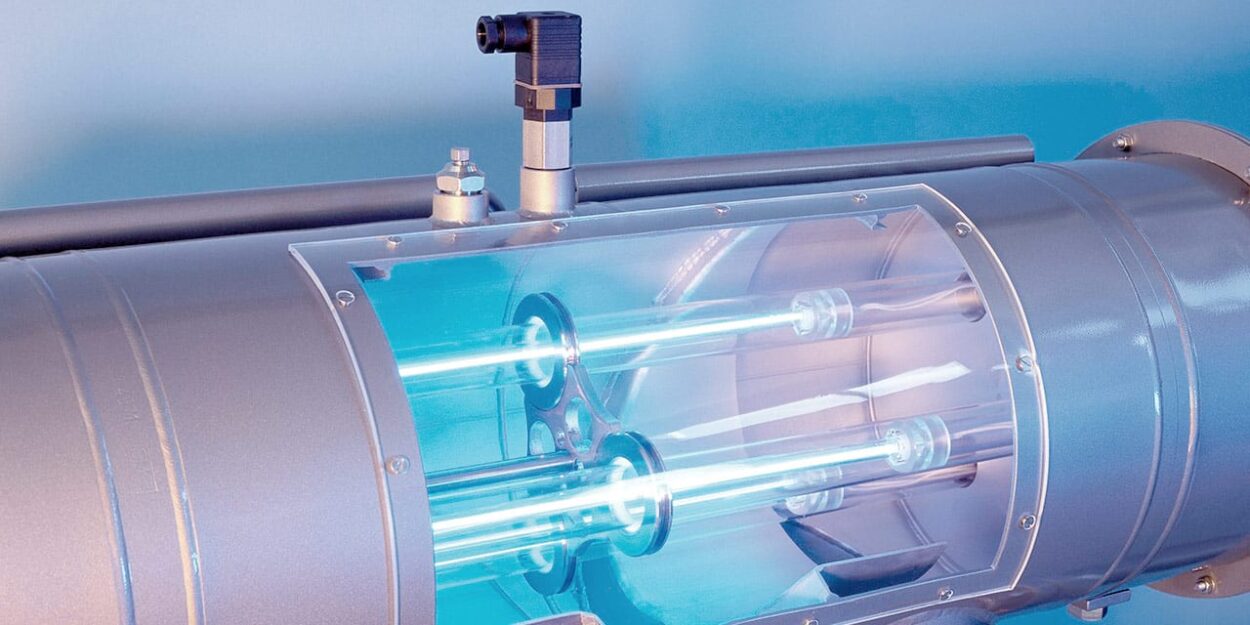

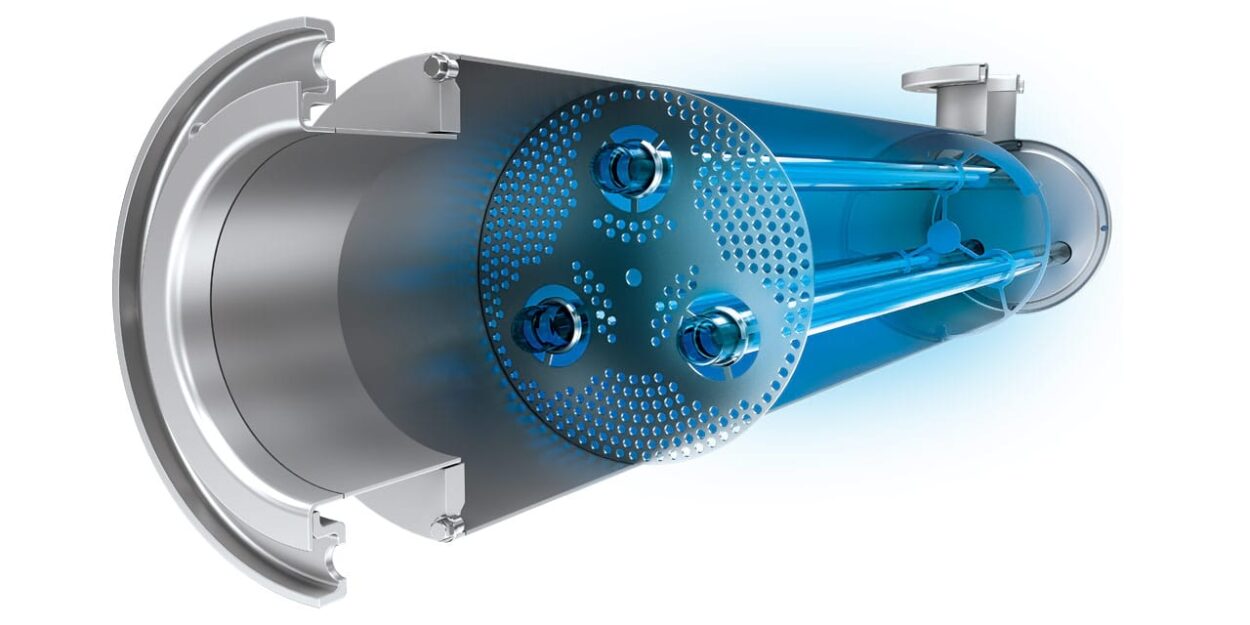

Romain Jombart, Director of Innovation and R&D, explains BWT ECO-UV consists of two technologies that have been brought together to enhance water quality without using chemicals.

“We were looking for a disinfection process that limited the use of chemicals and this solution involves the use of UV lamps and hydrogen peroxide. The UV has a specific length of 254 nm which can destroy the DNA of bacteria and most of the microorganisms in water. We emerge the lamps in the manufacturer’s installation and also add some H₂O₂ (hydrogen peroxide) which is really effective on biofilm.”

RELATED ARTICLE

H₂O₂ offers the major advantage of only degrading into water and oxygen – it oxidizes organic matter but does not generate by-products as chlorine or bromine do, he explains.

“So, when we use UV and hydrogen peroxide together, we have a very efficient and safe method of disinfection without any by-products that might be harmful for the environment.”

A Range of Industries Including Food & Beverage

A subsidiary of the Best Water Technology group, BWT France provides a range of full solutions in the field of water treatment, including equipment, chemicals and services.

It largely addresses domestic, industrial and commercial segments of the markets, offering a wide portfolio of technologies, says M Jombart:

“There is already strict regulation on the use of biocides in Europe and we expect increasing constraints on the quality of wastewater as well. Our hope is to convince our clients that this solution really is the best one for environmental protection.”

BWT ECO-UV is suitable for any industry where water disinfection is part of the manufacturing process, particularly food and beverage.

RELATED ARTICLE

The aim is to disinfect the water effectively without the need for harmful chemicals which are then released into the environment through wastewater after processing.

“We have had very good feedback from food and beverage customers, especially those with cooling stations, which have a huge risk of bacteriological developments, especially legionella. Other big users could be the energy sector, the automotive industry, and goods manufacturers – anyone who wants to reduce the impact of their waste on the environment,” he stresses.

99% Efficiency

BWT ECO-UV is easy to install and relies on a simple process, says M Jombart:

“The UV lamps are switched on and disinfect the water as it flows through, then, from time to time, H₂O₂ is injected to vaccinate the system. It is very safe and efficient and is easy to use. It also requires minimum maintenance.”

When used correctly and with effective pre-treatment and good monitoring, the process provides 99% efficiency, the level required of any disinfection process, says the company.

“ECO UV is very efficient but if you start with a very bad quality of water, then have bad maintenance and follow-up of the installation, it will be less effective. This is why we also offer pre-treatment, follow-up and maintenance to our clients.”

The plan now is to start testing much larger installations, those dealing with volumes of water greater than 50cbm.

The company is also looking into the creation and use of biochemicals from living plants and the technology of electrolysis.

“Our aim is to continue to focus on really strong disinfection of water,” M Jombart concludes. At the same time, we want to change people’s mentality towards water treatment, encouraging processes and products that are much more respectful to the environment.”