A few weeks ago, we wrote about how several firms such as Ferrari, McLaren, and Airbus were retooling their productions in order to manufacture medical equipment such as ventilators to help healthcare workers, as the crisis in many countries is getting worse. Airbus has just sent us today a timelapse showing how they managed to transform AMRC Cymru in Broughton, North Wales (England) from a research and development facility into an assembly line to produce medical ventilators for the UK in the fight against COVID-19.

Airbus is part of the Ventilator Challenge UK consortium, which brings together some of the world’s most innovative industrial, technology and engineering businesses from across the aerospace, automotive and medical sectors. Over 550 Airbus employees are working around the clock to produce at least 15,000 ventilators for the National Health Service.

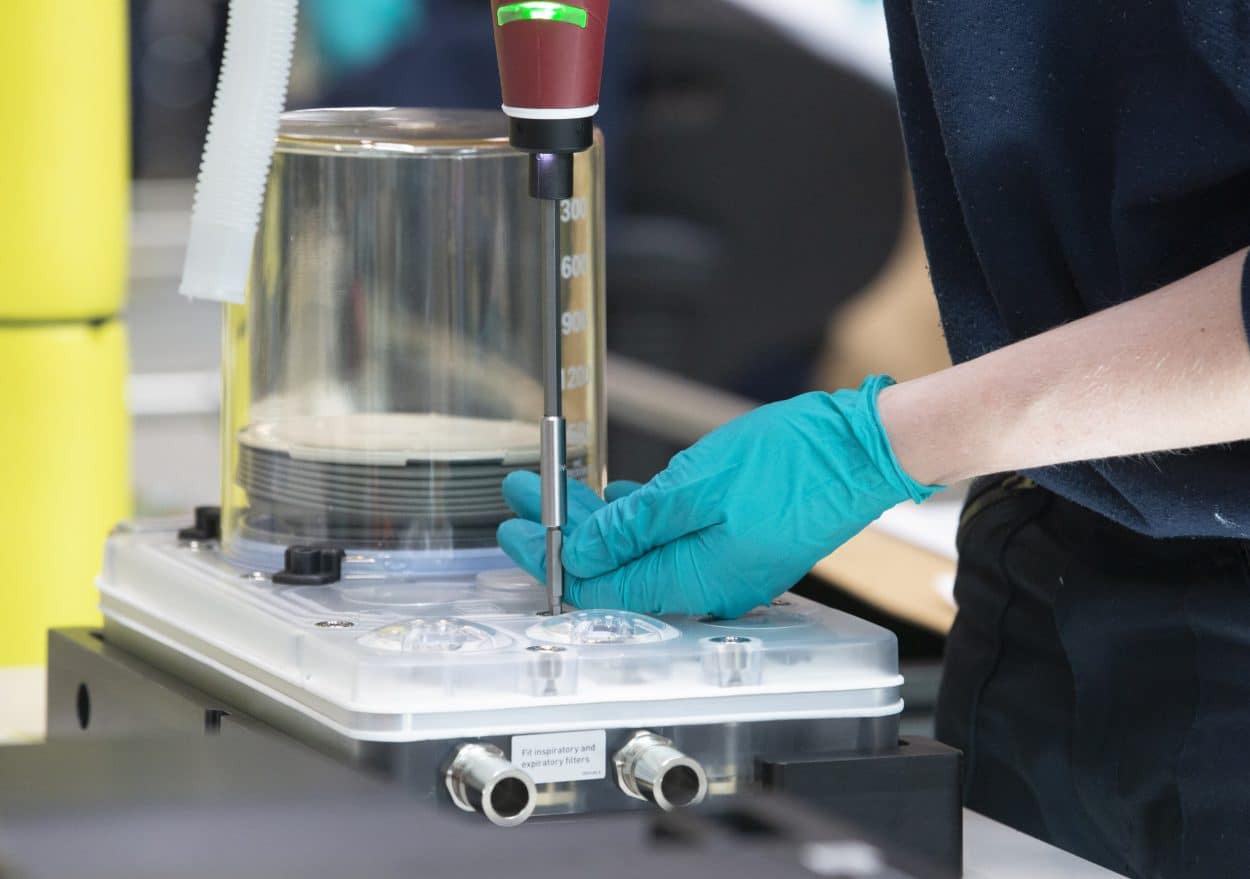

Following approval from the UK’s Medicines and Healthcare products Regulatory Agency (MHRA), Welsh government-owned AMRC (the Advanced Manufacturing Research Center of the University of Sheffield) will help build up to 1,500 Penlon Prima ESO2 ventilators each week. The device is a simplified version of an existing Penlon model and is the first new ventilator approved by the UK medical regulator in the fight against COVID-19.

Airbus is making about 50 percent of the parts of each finished ventilator at AMRC Cymru, assembling absorber units and flow meters. The finished parts then join up with ventilator units made by Ford in Dagenham and trolleys made by McLaren in Woking to make the finished unit. After final testing by Penlon in Abingdon, the ventilators are ready for supply to the NHS.