Preloading bearings is critical for precision and longevity in mechanical systems. In this article, Smalley expains how wave springs simplify this process, reduce wear, and enhance performance in high-speed applications.

By Alex Villagomez, Content Marketing Specialist at Smalley

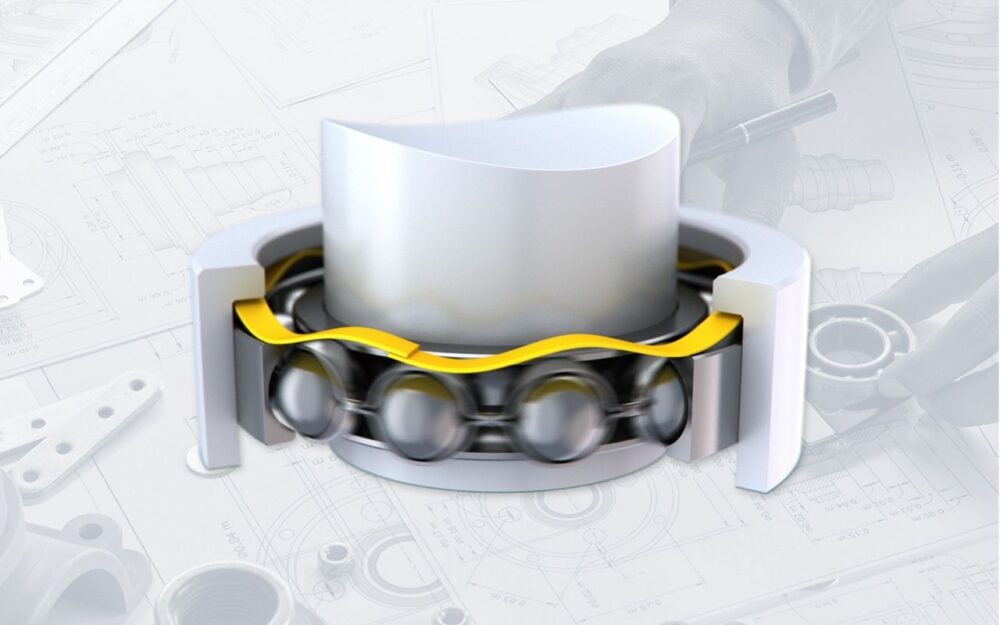

Bearings are designed to move freely, but manufacturing and assembly tolerances can introduce unwanted play between components. This clearance can lead to vibration, noise, and premature wear. Preloading a bearing solves this issue by applying a sustained axial load, ensuring constant contact between the bearing elements and races.

There are two primary methods for preloading: solid preload and spring preload. Solid preload uses a locking mechanism to hold the inner and outer races in place, but it can be complex and costly. The simpler, more cost-effective solution is spring preload, which uses a spring to apply a consistent axial force.

Why Choose Wave Springs for Preload?

Wave springs, particularly Smalley’s single-turn designs, are ideal for bearing preload. They provide the necessary axial load while compensating for tolerance stack-ups and thermal misalignments. This ensures smooth operation and reduces both axial and radial play.

The benefits of using wave springs for preload are significant:

- Axial and Radial Play Control: Wave springs maintain reliable contact between the ball complement and bearing races, reducing dimensional variation and improving stability.

- Reduced Wear and Longer Life: By evenly distributing loads, wave springs minimize stress on individual components, extending bearing life.

- Noise and Vibration Reduction: Preloaded bearings operate more quietly, even in high-vibration environments, improving overall system performance.

- Elimination of Ball Skidding: Constant force ensures smooth movement, preventing skidding that can damage bearings.

- Precise Shaft Positioning: Wave springs keep shafts centered, optimizing centrifugal balance in high-speed applications.

Selecting the Right Wave Spring

Choosing the correct wave spring is essential for achieving optimal preload. Too much force can shorten bearing life, while too little can lead to noise and instability. Smalley offers a wide range of standard parts in carbon and stainless steel to fit popular bearing sizes.

Two common configurations are gap-type and overlap-type wave springs. Gap-type springs have split ends, while overlap-type springs feature overlapping ends. Both designs allow movement around the circumference during compression, preventing binding, a common issue with traditional wave washers. For applications requiring higher preload forces, Smalley’s Nested springs provide a robust solution.

How Single-Turn Wave Springs Are Made

Smalley’s single-turn wave springs are manufactured using an advanced process called edgewinding. In this method, flat wire is wound on its edge to create the spring’s precise wave profile. Unlike traditional stamping, edgewinding offers superior flexibility and consistency. It enables quick production of custom diameters and configurations without the need for special tooling, making prototyping and modifications faster and more cost-effective. Additionally, edgewinding minimizes material waste because only the required wire is used, making it practical for exotic alloys. The process also enhances strength and performance thanks to circular-grain metallurgy, ensuring reliable preload in demanding applications.

The Bottom Line

Preloading bearings is vital for maintaining precision, reducing wear, and ensuring long-term reliability. Wave springs offer a simple, efficient, and cost-effective way to achieve these goals. With their ability to control play, reduce vibration, and accommodate tolerance variations, wave springs are indispensable in high-speed and high-precision applications.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)