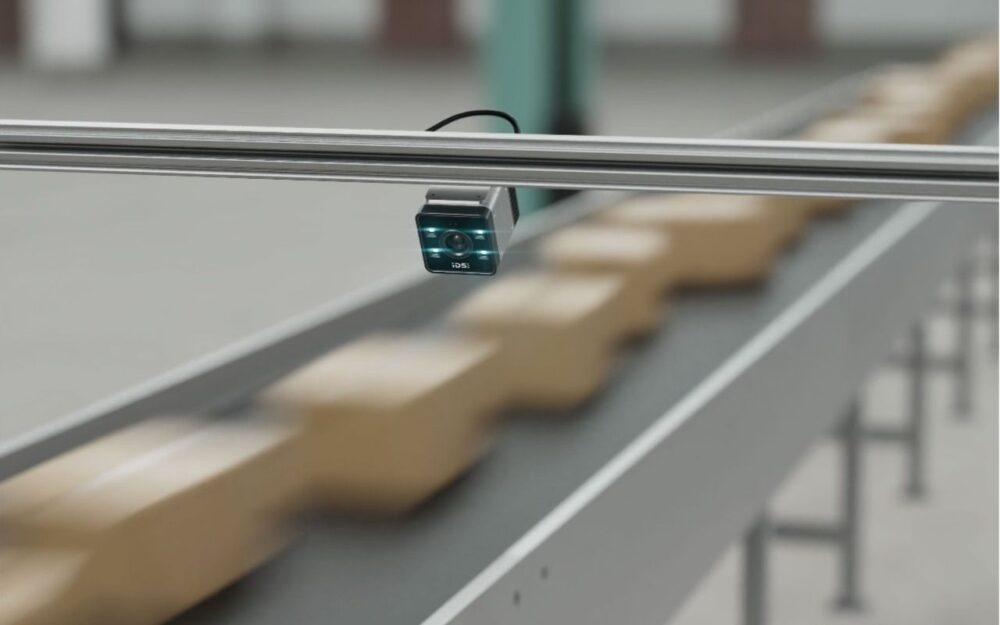

The Nion 3D camera by IDS sets new standards in ToF-class imaging, delivering high-resolution depth images in real time, even under movement or changing light conditions. Its versatility makes it ideal for logistics, warehouses, and industrial applications, simplifying package handling, order picking, and automated transport. Nion performs reliably in every environment, ensuring faster, safer, and more efficient operations.

By Silke von Gemmingen, Communication Specialist – Corporate & Product at IDS

The new Nion 3D camera takes Time-of-Flight (ToF) technology to the next level, setting new standards in resolution, speed, and robustness. With high-resolution depth sensing, real-time processing, and rugged performance, Nion enables faster, safer, and more flexible operations across industries, from logistics and warehouses to industrial automation and robotics. Designed to deliver reliable results in every environment, it overcomes challenges that limit conventional 3D sensors.

High-resolution imaging for detailed recognition

At its core, Nion features the 1.2-megapixel AF0130 sensor from onsemi’s Hyperlux ID family. With up to four times the pixels of conventional VGA ToF cameras, it can detect small parcels, irregular shapes, and narrow storage spaces with high precision. This level of detail is crucial for order picking, sorting, quality inspections, and other applications requiring exact measurements.

Depth with detail: new 3D camera, new precision

Real-time depth sensing, even in motion

Depth data is calculated directly on the sensor via on-chip processing, combined with global shutter and pixel-level memory. With a modulation frequency of up to 200 MHz, Nion delivers latency-free 3D images, even when packages move rapidly on conveyors or are handled by robotic arms. On-chip processing also produces intensity and confidence maps, reducing external computing requirements and simplifying integration – capabilities that clearly set Nion apart from conventional ToF solutions.

Reliable performance in every environment

Warehouses and production areas can vary in lighting, dust, and temperature. Nion’s 940 nm laser illumination, tuned to the sensor’s sensitivity, ensures accurate depth sensing even under bright sunlight, artificial light, or low-light conditions. Its IP67-rated housing protects against dust, splashes, and harsh industrial conditions, while maintaining precise measurements across surfaces and object types. Whether in a warehouse, a factory floor, or an outdoor logistics hub, Nion delivers consistent, high-quality 3D data.

Easy integration and scalable systems

Nion integrates seamlessly via GigE Vision and a user-friendly API, allowing conveyor systems, automated storage, and mobile robots to be quickly equipped and scaled. While particularly valuable for logistics applications, Nion also supports industrial automation, robotics, and quality control, providing flexible, high-performance 3D vision for any environment.

Performance at a Glance

By combining next-level resolution, on-chip processing, and rugged design, Nion helps companies increase efficiency, reduce errors, and implement flexible, automated processes. With performance for every environment, it sets a new standard for 3D vision in logistics and beyond, giving organizations the tools to optimize operations and future-proof automation strategies.

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)