Retaining rings play a crucial role in securing components in demanding applications, such as power tools. Yet, the number one cause of failure is not the ring itself but groove deformation. In this article provided by Smalley, you will understand why grooves fail and how to prevent those failures to avoid costly repairs, safety risks, and damage to your product’s reputation.

Content provided by Smalley

Retaining rings may seem like simple components, but they play a critical role in holding parts together under demanding conditions. When they fail, the impact can be significant, resulting in unexpected downtime, costly repairs, and even safety risks.

So, what is the leading cause of retaining ring failure? Surprisingly, it is not the ring itself. Groove deformation accounts for nearly 90% of failures, making it the most overlooked factor in design and maintenance.

Why Groove Deformation Happens

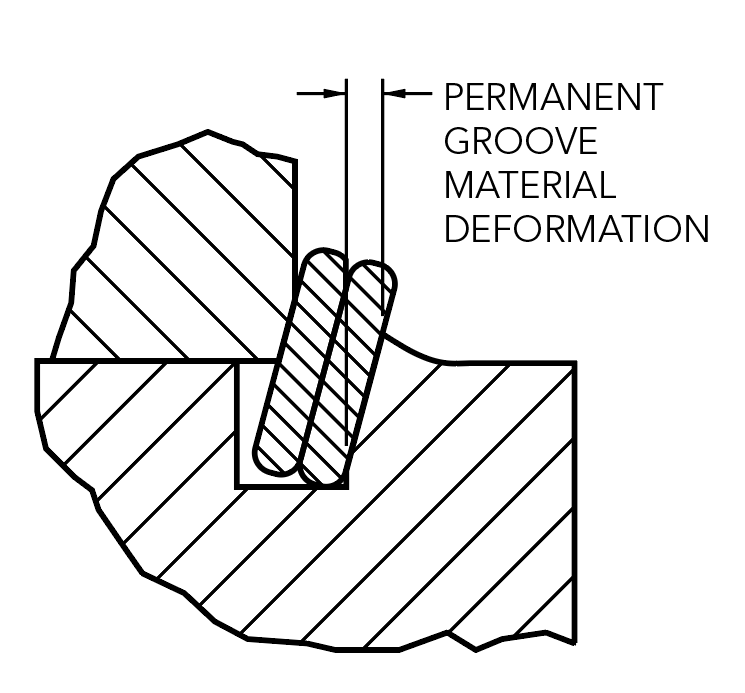

Groove deformation occurs when the groove material, whether in a bore or shaft, has a lower yield strength than the ring. Under excessive thrust loads, the groove wall can compress or dish, creating a compromised surface that allows the ring to twist, expand, and eventually pop out.

Impact loads present another challenge. Sudden shocks can cause the ring’s diameter to expand or contract, depending on whether it is installed in a housing or on a shaft. Over time, cyclic loading and vibration can also cause the ring to loosen from its groove.

Design Strategies to Prevent Failure

The good news is that groove deformation is preventable with the right design considerations:

1/ Choose Stronger Bore/Shaft Materials

If your application involves high thrust loads, select a bore/shaft material with a yield strength equal to or greater than the ring’s.

2/ Increase Groove Depth

A deeper groove provides more support and reduces the risk of deformation under stress.

3/ Account for Impact Loads

If impact loading is expected, increase the interference fit between the ring and groove or use a heavier cross-section. Square-edged wire designs, such as Constant Section Retaining Rings, can also improve retention.

Groove Geometry Matters

Beyond material strength, groove geometry plays a critical role in retention capacity. Smalley engineers recommend the following guidelines:

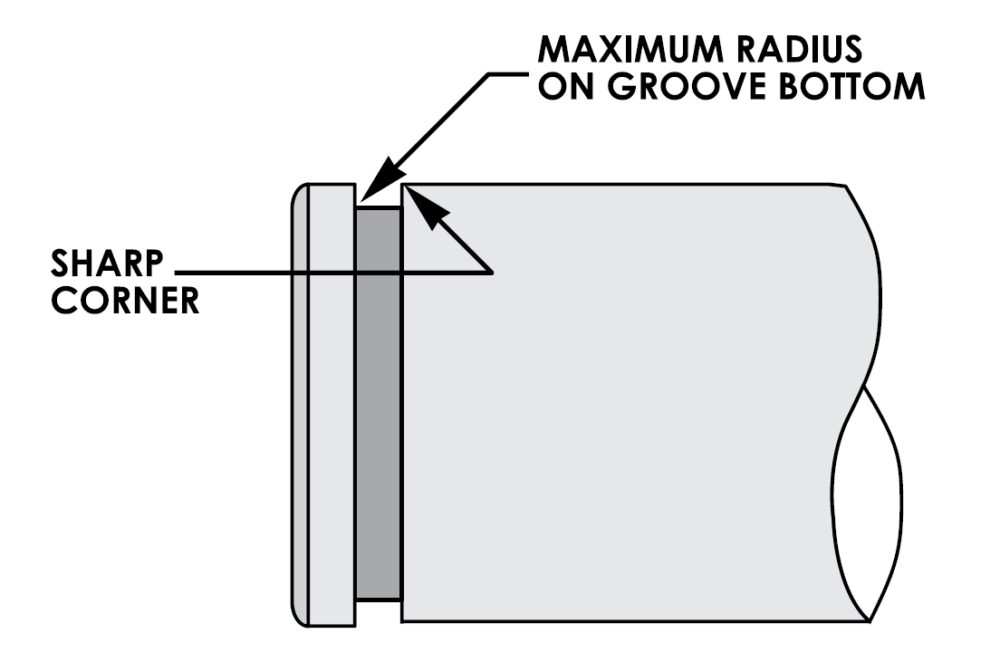

1/ Flat Groove Bottom

A flat bottom ensures proper ring engagement. Avoid excessive radii—keep it under .005 in. for rings 1 in. and smaller, and under .010 in. for larger rings.

2/ Sharp Corners

Sharper corners maximize contact with the ring, reducing the chance of rolling out.

3/ Adequate Groove Depth

At least one-third of the ring’s radial wall should sit in the groove to minimize leverage forces.

4/ Proper Edge Margin

Position grooves at least three times their depth from the edge of the bore or shaft to maximize strength.

Confirming Fit and Function Before Production

Every application is unique, and real-world conditions can vary. Thankfully, Smalley offers free samples of in-stock standard parts, including Constant Section Retaining Rings and many other products, so you can validate performance before committing to production.

If your design requires a custom solution, Smalley can work with you to create a prototype that ensures the perfect fit for your application. Our engineering team is ready to help optimize groove geometry, material selection, and ring design to meet your specific requirements.

Key Takeaway: Reliability Starts at the Groove

Groove deformation is not just a minor issue. It is the leading cause of retaining ring failure and can compromise the integrity of your entire assembly. Thankfully, this risk is preventable. By selecting materials with adequate strength, optimizing groove geometry, and validating performance under real-world conditions, you can significantly reduce the chance of failure.

Pair these best practices with Smalley’s engineering expertise, free samples, and custom prototyping options to ensure your design performs as intended. Reliability begins with proper design and testing, and Smalley is here to help you achieve it.