Italian industrial automation leader Comau has just announced a strategic collaboration with Michigan-based startup Intecells to integrate cold plasma technology into existing industrial cell production lines. This partnership is set to significantly improve the performance, cost-efficiency, and environmental footprint of battery cell production.

Cold Plasma: A Disruptive Force in Cell Manufacturing

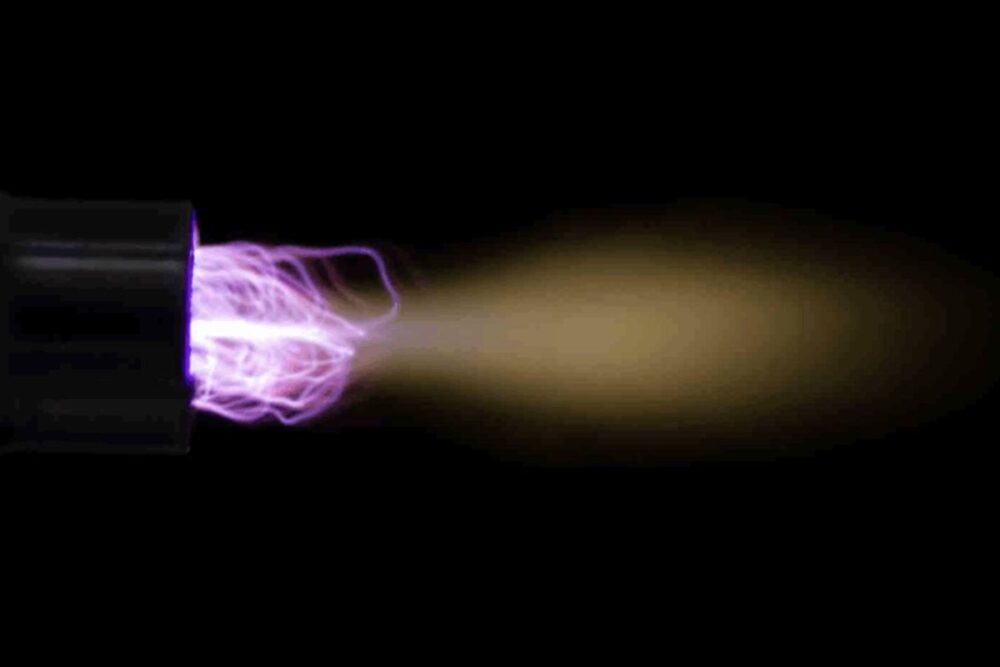

Cold plasma, a partially ionized gas that operates at near-room temperatures, is an emerging technology with multiple industrial applications. In the battery sector, Intecells has patented a breakthrough application of cold plasma to replace or enhance traditional impregnation and drying processes, reducing energy consumption and improving cell performance and durability.

According to Comau, the plasma-based solution already available can shorten cycle times, decrease energy use, and enhance production quality across a wide range of battery chemistries.

But that’s just the beginning. A more advanced version of the technology, currently under development, aims to streamline production steps dramatically—potentially cutting capital expenditures, energy consumption, and carbon emissions by 50%.

Strategic Collaboration for Scalable Industrialization

This initiative is more than a tech integration. It’s a strategic vision to accelerate electrification and support manufacturers in modernizing their production systems. Comau will leverage its longstanding expertise in battery production—from cell formation to module and pack assembly, including end-of-life disassembly and recycling—to validate and scale Intecells’ solution in real industrial settings.

“Our collaboration with Intecells marks a decisive step in redefining battery cell manufacturing,” said Gian Carlo Tronzano, Head of Comau’s Battery Cell Global Competence Center. “We’re combining Intecells’ disruptive technology with our automation know-how to validate next-gen plasma processes for scalable production environments.”

For Intecells, which is led by materials scientist and former General Motors battery expert Xiaohong Gayden, the partnership with Comau brings both industrial credibility and international reach.

“This partnership empowers us to accelerate development, revolutionize cell manufacturing, and support global customers,” Gayden stated.

Industry Impact

This collaboration comes at a time when the battery industry is under mounting pressure to scale production while meeting sustainability targets and cutting costs. By targeting multiple pain points—energy usage, production complexity, and material performance—cold plasma could become a key enabler in the next phase of industrial battery innovation.

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)