Conventional fuels used in the aviation industry harm the environment. A recent EU regulation pushes for greener alternatives to conventional fuels to meet the neutrality goals set for 2050. However, sustainable aviation fuels (SAFs) are costly, and Europe has limited production capacity for them. The European aviation industry must find a way to adopt these fuels cost-effectively, such as producing microalgae-based aviation fuels to make flying more environmentally friendly.

In the EU, civil aviation contributes over 13% of total CO2 emissions from transport, making it one of the sector’s largest sources of greenhouse gas emissions. One way to make the aviation industry more sustainable is by relying on sustainable aviation fuel (SAF) instead of conventional aviation fuel. This could lead to a reduction in CO2 emissions by as much as 80%.

In 2023, the European Parliament approved the ReFuelEU Aviation regulation, which aims to increase the use of SAF in line with the EU’s climate neutrality targets. According to the new rules, starting in 2025, a minimum of 2% of aviation fuels must be sustainable; this percentage will rise every five years, reaching 70% by 2050.

What is Sustainable Aviation Fuel (SAF)?

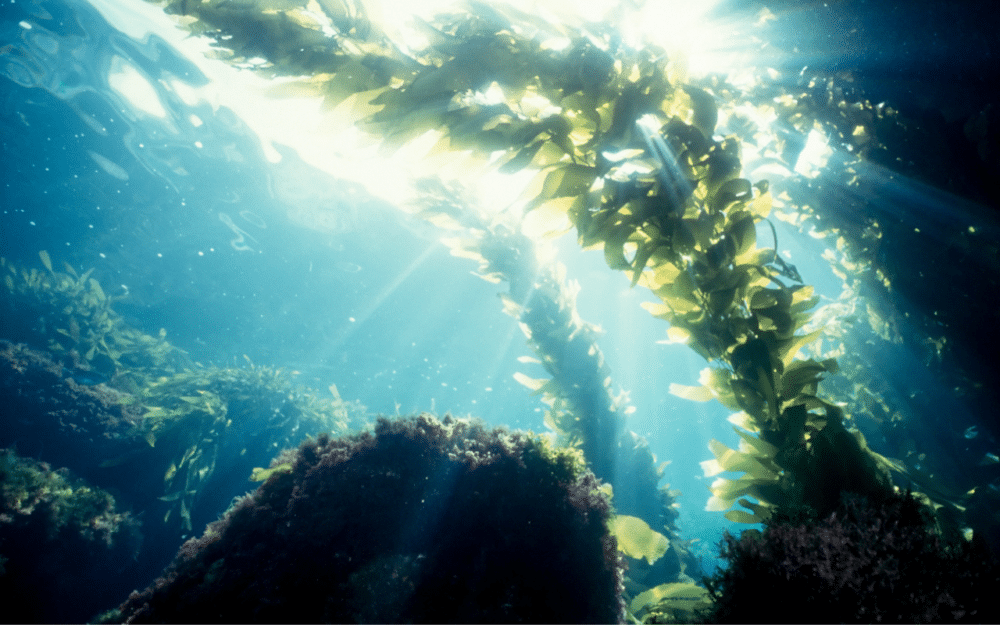

SAF is a cleaner alternative to traditional aviation fuel, derived from plant or animal materials instead of fossil fuels. Various sources can be used to produce SAF, including cooking oil, animal waste fat, agricultural and forestry waste, and even algae. It is designed to be nearly identical to conventional fuel, which allows it to be used in existing planes. For now SAF still needs to be mixed with traditional aviation fuel, but there are hopes that airlines will be able to use 100% SAF by 2030.

The challenge is that SAF prices can be up to 10 times higher than conventional fuel, although they are expected to decrease significantly with new production technologies.

Ronald Halim, professor at the School of Biosystems and Food Engineering at University College Dublin and project coordinator of the SusAlgaeFuel Project, says that relying on food waste limits SAF supply.

“The main source of sustainable aviation fuel at the moment is crops that have food uses and require agricultural land for cultivation. These are second-generation crops, meaning they are generally waste products from other systems or processes, such as used cooking oil. These sources are either unsustainable or have limited availability. There is a need for an alternative approach to produce sustainable aviation fuel, and that’s where microalgae can potentially come in.”

READ ALSO

What are the advantages and possible challenges of using algae-based fuels?

Algae-based fuel is gaining popularity in aviation due to its ability to grow in saltwater or wastewater, absorb CO2 from the atmosphere, and produce oil with minimal land uses , which means it doesn’t affect food production. The European algae biofuel market is expected to expand to $1.97 billion by 2033 at an annual growth rate of 6.89%.

“Algae offers several benefits for fuel production. Firstly, they are very oil-rich, meaning they contain significantly more oil per gram compared to oil-rich crops like oil palm or canola. Secondly, they grow rapidly, allowing for a quicker turnover time than conventional crops. For instance, traditional crops may require up to a year before harvesting for oil production, while microalgae can be harvested every 1 to 2 weeks, enabling a shorter growth cycle. This could lead to increased production,” said Professor Halim.

One of the main obstacles to transitioning to algae biofuels is the high cost of converting microalgae lipids into aviation fuel. Algae require nutrients, a specific temperature, and water to grow. Once the algae biomass is obtained, processing it demands a significant amount of energy.

Professor Halim’s SusAlgaeFuel Project is developing approaches to lower the cost of growing and processing algae. This can make the resulting algae fuel cost-competitive with other types of sustainable aviation fuels, and make it available for local production in the EU.

Working towards a cost-effective and sustainable solution

The SusAlgaeFuel project brings together technology providers specializing in microalgal cultivation and AI-driven sensor technology, along with experts in biomass processing and aviation fuel synthesis from five European countries, all collaborating to make the aviation industry more environmentally friendly.

Their approach involves cultivating algae using wastewater from the anaerobic digestion sector rather than relying on expensive clean water and nutrients. Using waste nutrients can lower the cost of algae production while simultaneously treating waste. This creates a win-win situation: The anaerobic digestion industry can convert its waste into valuable biomass, and the aviation sector benefits from lower sustainable fuel costs.

“I sincerely hope we can generate innovative science that is beneficial to scientists and industries worldwide. I want our results to serve industry stakeholders and potentially be translated into commercial applications, perhaps not during the project but shortly after its completion. This way, we can have an impact beyond just scientific publications; we can influence actual commercialisation in the aviation and anaerobic digestion sectors in Ireland and the EU,” said Professor Halim.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)