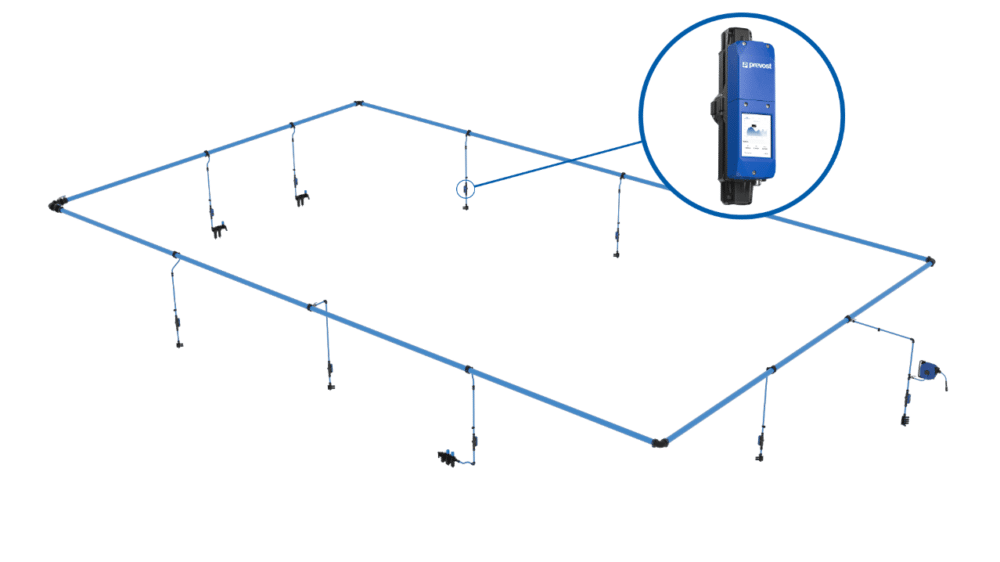

At the Hannover Messe trade show, Prevost proudly introduced the newest addition to its Prevost Piping System: the PPS AMS. PPS AMS (Air Monitoring System) is an air monitoring technology that combines an automatic valve with specific sensors to monitor and control compressed air installations. The crucial values of energy saving, and leakages costs can be constantly under control and calculated easily and immediately.

Content provided by Prevost

Revolutionary Monitoring Capabilities

The PPS AMS offers continuous monitoring and delivers a detailed series of fundamental information, fundamental for every compressed air installation which are: precise leakage detection and their cost, safety alerts, minimum and maximum pressure and temperature, cost of the air in the entire system and up to date cost saving. Additionally, users can automatically or manually control the air flow. In case of emergencies, this functionality helps prevent significant damage or air loss. Under normal circumstances, it gives the possibility to maximize system performance, potentially improving efficiency by up to 40%.

Key Information Provided by PPS AMS

The type of information provided by PPS AMS is essential. It includes leak detection, which covers both the volume and live costs of leaks. Additionally, it offers flow monitoring, detailing the volume and live costs associated with airflow. Pressure levels are consistently monitored to ensure system stability. The dew point is measured to maintain optimal air quality. The functionality of valves is tracked to ensure they operate correctly. Furthermore, fluid controls are optimized for efficient system performance.

Seamless Data Transmission

The device, consisting of the valve and sensors, can be installed at each drop and monitored remotely. PPS AMS allows easy and instant access to data through Bluetooth, Io-Link, or reports. This feature enables users to keep key performance indicators (KPIs), produce reports, analyse system costs, create statistics, and generate graphical representations of the data. This also allows users to manage the valve through manual, automatic, or timer settings and set the parameters with minimum and maximum values (like temperature and pressure).

Effective Alarm System

The system includes a complete set of alarms, ensuring users can quickly identify and resolve issues. Safety alerts warn users if the flow goes beyond or falls below the preset parameters, allowing immediate intervention through the valve. Pressure alarms signal potential problems if pressure falls outside the user-defined minimum and maximum parameters. The measurement and online monitoring of relative humidity in gases, or the environment are vital for the processing industry to maintain process control and quality assurance.

Real-time preventive monitoring of critical humidity parameters can detect early signs of corrosion in machinery and pipework, thereby enhancing the service life and reliability of systems. Humidity measurement is especially critical in processes within the food and pharmaceutical industries to ensure product quality and safety.

Additionally, monitoring ambient humidity contributes to energy efficiency by optimizing humidity levels in production environments, as well as in intake air from fans or compressors. Temperature alarms alert users if the temperature exceeds the set limits. Leak detection monitors the actual cost of compressed air and leakages, helps prevent losses by more than 50%, and identifies even micro-leakages.

Industry Impact and Environmental Benefits

The impressive suite of features offered by PPS AMS makes it an essential tool to have a lean management of compressed air systems. Additionally, it contributes to improving companies’ carbon footprints and aligns with the modern industry trend towards Industry 4.0. PPS AMS supports compliance with DIN EN 50001, which regulates compressed air measurement norms, further promoting environmental sustainability.

Anticipated Release

Prevost’s presentation at Hannover Messe highlights the significant advancements in air monitoring technology, promising a future of enhanced system control, cost savings, and environmental stewardship.

PPS AMS is expected to be officially released in 2026. In the meantime, discover Prevost Piping System, the 100% aluminium compressed air system.

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)