France represents the largest market for Etex, a global building materials company specializing in lightweight construction solutions. Our reporter Erin Tallman visited three of its centers located in Mazan, Carpentras, and Avignon for a closer look.

Following the grand opening of its Bristol factory, Etex invited us to a guided press tour of three significant locations in the Provence region of France: Mazan, Carpentras, and Avignon. France plays a crucial role in Etex’s global operations, contributing approximately 20% of the company’s revenue. The tour allowed us to explore firsthand how Etex is utilizing its expertise in plasterboard production, research and development, and sustainability practices to drive innovation across the construction industry.

The day’s visits also gave a glimpse into Etex’s role as a leader in sustainable construction materials. Their Mazan quarry integrates plasterboard recycling to reduce gypsum extraction. The R&D pilot line in Carpentras is pioneering the world’s first 100% recycled gypsum plasterboard. In their Innovation Technology Center (ITC) in Avignon, groundbreaking products like Aquaboard and Weather Defence are tested. Etex is committed to pushing the boundaries of what is possible in sustainable construction.

Etex in France: A Key Market for Sustainable Growth

France is Etex’s largest and most important market. With a strong workforce of nearly 1,800 employees across 18 sites, Etex’s French operations are a crucial part of its global strategy. France is home to several of Etex’s leading brands. These include Siniat, which is recognized for its technical plasterboard solutions, as well as Promat, URSA, Cedral, EQUITONE, and Eternit, which together form a robust portfolio of high-performance construction materials.

Etex’s Building Performance division, led by Siniat, is at the forefront of technical innovation in plasterboard. They are developing solutions that are high-performing and environmentally responsible. The company’s dedication to sustainability is evident in its commitment to reducing its carbon footprint and optimizing resource use across its French operations. In 2024, these efforts were recognized. The Etex site in Saint-Loubès was awarded the “Trophée USINE RSE de l’année” for its outstanding management of water resources.

Its comprehensive training and customer support programs ensure that clients can fully leverage the company’s cutting-edge solutions. These numerous attributions have established Etex as a trusted partner in the French construction industry.

Touring Etex’s Key Sites in Provence: Mazan, Carpentras, and Avignon

The Mazan Quarry

Our first stop was the Mazan quarry, the largest open-cast gypsum quarry in France. This historic site, which began as an underground operation in 1924, now spans 700 meters long and 400 meters wide. 350,000 tonnes of gypsum are extracted annually. What sets this quarry apart is its strong focus on environmental preservation. Etex has implemented a thorough biodiversity monitoring program that protects local flora and fauna, including species like red squirrels, woodlarks, and various types of bats.

Etex also aims to minimize gypsum extraction through recycling efforts. The Mazan quarry recycles plaster waste, reducing the need for raw material extraction by 100,000 tonnes per year. This prolongs the life of the quarry, ensuring gypsum availability for future generations.

“The more we recycle, the longer the quarry will last, and that’s the goal—creating a circular economy that benefits the environment and our business,” Vivien Bonnelles, Industrial Director, South East, Etex France BP, stated during our guided tour.

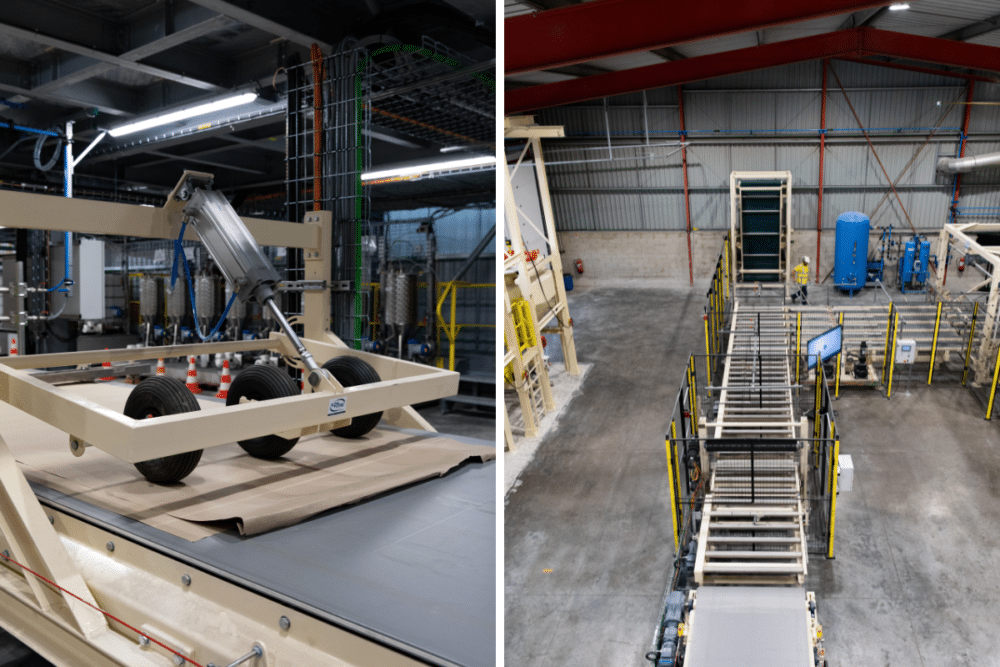

The Carpentras Pilot Line

Next, we visited the Carpentras R&D pilot line, a €5 million investment inaugurated in September 2022. This 1,200m² facility is dedicated to developing and testing plasterboard innovations. Unlike traditional production lines, the pilot line allows for rapid prototyping and testing of new formulations without disrupting industrial-scale operations. More than 120 R&D tests are conducted annually at the site. There, Etex successfully developed the world’s first 100% recycled gypsum plasterboard. This is a major step forward in the company’s mission to reduce its environmental impact.

The ITC in Avignon

The final stop on our tour was Etex’s Innovation Technology Center (ITC) in Avignon. This state-of-the-art facility has been at the forefront of plasterboard research and development for over 20 years. The ITC’s focus areas include decarbonizing products, promoting the circular economy, and developing new technologies for exterior applications of plasterboard. Products such as Aquaboard and Weather Defence, which are designed for ventilated cladding and timber-frame construction respectively, were developed and rigorously tested at this facility. Between 2019 and 2024, the ITC filed 30 patents and launched 59 new products.

New Product Announcements: Revolutionizing the Industry with Recycled Materials

Etex is taking significant steps to revolutionize the construction industry with the announcement of several new products, each designed to enhance sustainability and performance. The most groundbreaking of these is the 100% recycled gypsum plasterboard. This product will be exclusively manufactured in France before being expanded to other countries. This plasterboard is composed almost entirely of recycled materials, and its launch represents a significant milestone in Etex’s commitment to advancing the circular economy. The product will primarily target clients involved in large-scale projects who are seeking eco-certifications.

Another exciting innovation is the introduction of Resiclip, a DIY-friendly partition system. This system allows for the easy installation of plasterboards, which feature a pre-cut slit on the side that fits with metal strips. The innovative design eliminates the need for joint strips, making installation faster and simpler for non-professional users. This product is expected to resonate with the growing DIY market.

Etex has also developed Pregytwin Up, a new plasterboard that is 25% lighter than its predecessor, yet still offers superior acoustic performance—ideal for venues requiring high sound insulation, such as cinemas and theaters. This improves ease of installation and reduces the carbon footprint associated with transportation and handling.

These product announcements underscore Etex’s dedication to combining performance and sustainability, ensuring that the company continues to lead in innovation while reducing its environmental impact.

“While there will never be enough waste to produce all of our products from recycled materials, we are committed to finding new ways to increase our use of gypsum waste and deliver sustainable solutions to the market,” Eric Bertrand, Innovation Director, R&D, stated during our guided tour of the Pilot Line in Carpentras, France.

With its strong presence in France, commitment to innovation, and focus on sustainable building solutions, Etex is well-positioned to continue shaping the future of construction—both in France and across the globe.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)