During our coverage of Global Industrie last week, there was one innovation that caught our attention: the connected warehouse. This is the first time that the French trade show dedicated an entire space to this theme, where technological advancements have been significant in recent years. With our analyst Hicham Dhouibi, we toured this connected warehouse and met 5 companies offering directly deployable solutions.

For the first time, Global Industrie, the French industrial trade show that took place in Lyon last week, integrated a dedicated space for logistics, maintenance, and security. 200 companies gathered over 2,000 square meters. The connected warehouse, created in partnership with Proxinnov, offers immersive experiences in the world of logistics with robotic and pure logistics solutions. The goal was to provide an educational tool to engage with industrialists and young people, introducing them to all the logistics professions.

For Julie Voyer, the show’s director, this addition to the fair was completely natural:

“Global Industrie must be global. That doesn’t mean covering everything exhaustively, but it does mean at least being able to offer key sectors a representative range of solutions. Logistics came from listening to the market, listening to the field, and particularly to professional organizations.”

We toured the connected warehouse with our industry analyst Hicham Dhouibi, looking for solutions that could help logistics in the future.

Here is a list of the 5 companies we met.

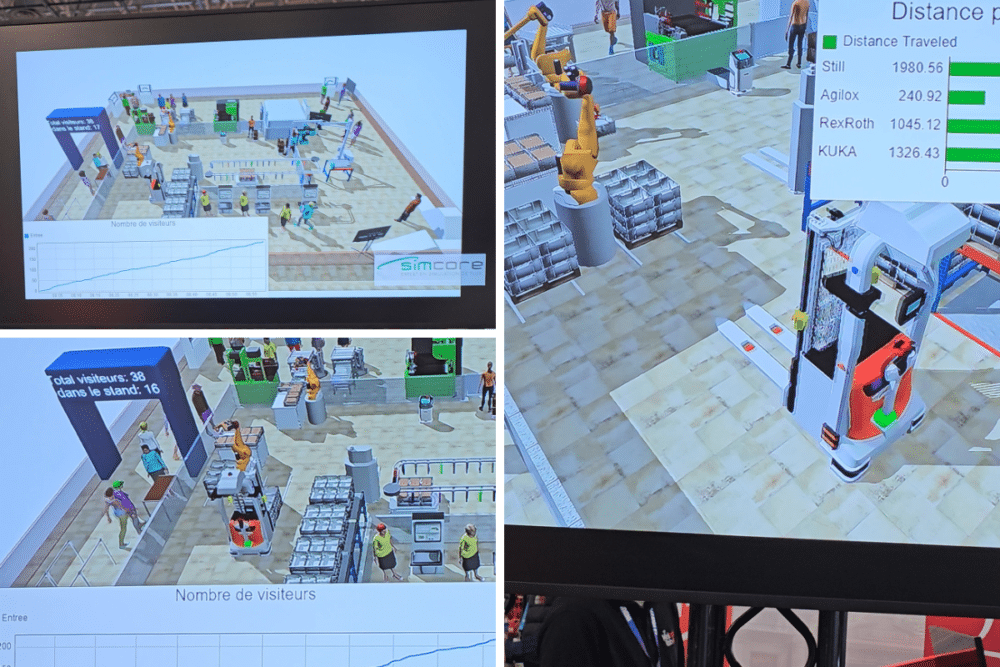

1/ Simcore: Optimization and Simulation for Intelligent Logistics

Simcore is a French company specializing in the simulation and optimization of logistics and industrial flows. With advanced 3D modeling technologies, Simcore helps companies design, improve, and secure their processes.

We met Sébastien Le Tutour, Director of Simcore, who told us more about the solution:

“The first step is to precisely dimension the needs. To do this, we collect the plans and data from integrators and simulate different scenarios to determine the optimal number of vehicles, the required storage capacity, and the smoothness of the flows in a given facility.”

Thanks to a 3D representation of warehouses and production lines, Simcore enables the testing of various scenarios:

“We can manage activity peaks and average flows, simulate order books and manufacturing constraints, validate shipping capacities, or even identify optimization areas.”

Anticipating the Unexpected and Virtual Improvements

The solution also anticipates the impacts of changes before actual implementation by making virtual modifications.

“For example, we can change the order of order launches, add a machine, and see its effect on production. If we see we’re falling behind due to a breakdown, we can decide to start a machine, add operators to catch up. All of this can be tested before being implemented.”

By testing these adjustments virtually, companies can make informed decisions, reduce risks, and optimize their performance safely.

A Solution Suitable for Large Companies as well as SMEs and VSEs

Simcore tells us that they address a wide range of players, from large industrial groups to SMEs and VSEs with specific needs. For large companies like Decathlon or Tefal, their solution is mainly used for managing automated warehouses, complex industrial flows, and advanced logistics. For SMEs and VSEs, it’s used for targeted project support, particularly for manufacturers of special machines offering small-line solutions.

2/ 3 Bosch Rexroth Solutions for Simple and Efficient Logistics

Ana Martins, automation engineer at Bosch Rexroth, presents the company’s innovations designed to optimize industrial production through ergonomics, automation, and collaborative robotics.

An Ergonomic and Smart Workstation

Bosch Rexroth first offers an ergonomic workstation specially designed to improve the working conditions of operators on assembly lines. This workstation offers several features including a height adjustment to suit the user’s needs, an adjustable pick-to-light lighting system to optimize visibility, an Interactive assistance through an instruction aid system, ideal for multi-product lines. It also enable to Optimize of assembly time, allowing method engineers to precisely evaluate production durations.

“This workstation also integrates the connected Nexus screwdriver, capable of automatically sending the required torque and indicating to the operator if the operation was performed correctly before moving on to the next step.”

ACTIVE Shuttle: A Revolution for Intralogistics

The ACTIVE Shuttle is an autonomous robot designed to optimize intralogistics flow by transporting dollies. It offers several advantages including the ability to navigate through very narrow aisles. A gleet management system allows multiple tasks to be performed simultaneously and improves the productivity of manufacturers.

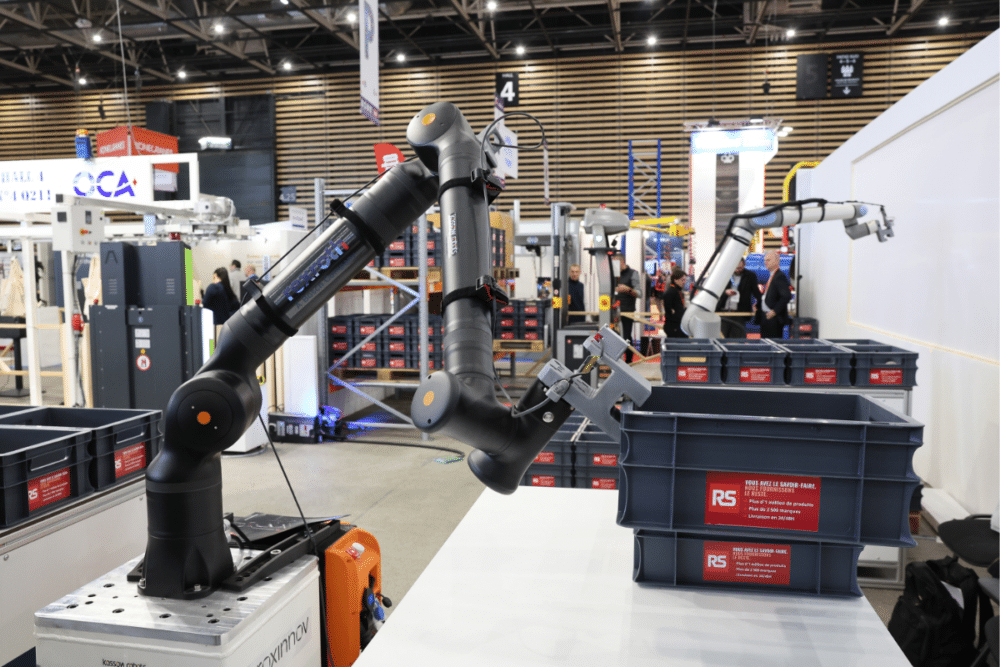

Kassow: The Collaborative Robot with Seven Axes

The Kassow robot, recently acquired by Bosch, stands out for its versatility: This collaborative robot is equipped with integrated force sensors, enabling it to work safely alongside humans. But it is also a high-performance industrial robot, capable of operating at high speeds.

“The great advantage of this robot is its seventh axis. Thanks to this, we were able to create this depalletizing application where it can insert full bins into the system and retrieve the empty bins afterward. And it’s thanks to this seventh axis that it can reach very tight spaces and avoid obstacles.”

Major Advances in Robotics

Since Kassow’s integration into Bosch Rexroth, several innovations have emerged, notably the Edge model, which improves the compactness and efficiency of the robot:

“We were able to reduce the embedded controller at the base of the robot. This means that when we really need restricted space for the robot, all the inputs, outputs, and communication are now integrated into the robot’s base. It’s just five centimeters taller, but we remove the entire controller. Additionally, it can be powered by 48 volts, meaning it can be directly connected to an AMR’s battery.”

Simplified Programming for Easier Adoption

With the shortage of specialists in automation and robotics, Bosch Rexroth is also focusing on simplified programming to make the technology more accessible:

“We have an intuitive interface inspired by educational software, based on a drag-and-drop block system.”

The Kassow ecosystem also integrates third-party manufacturer solutions (cameras, grippers), with pre-configured blocks for quick and efficient setup.

3/ Quality Control by AI with APREX Solutions

APREX Solutions is a company specializing in industrial vision and image analysis. It develops custom applications to detect defects and monitor manufacturing processes in the industry. Through artificial intelligence and advanced image analysis technologies, APREX thus enhances quality control and optimizes production.

Precise Defect Detection

One of the key strengths of this technology lies in its ability to detect anomalies on industrial parts, thanks to AI, as explained by Hélène George, communications manager:

“For a part like this to be compliant, it must have all the caps, have a label, and not have any cracks on the cap.”

APREX has therefore developed a supervised artificial intelligence model capable of identifying and classifying defects in real time. When a part passes under the camera sensor, the system can precisely determine the nature of the defect: the absence of an element, the presence of a crack, or any other issue that could affect the product’s conformity.

Real-Time Monitoring for Optimized Production

The tool also provides a compliance percentage, allowing operators to monitor the quality of production in real time. The history of the latest analyses helps quickly identify the origin of a problem, thereby facilitating interventions to adjust manufacturing parameters.

“This can give an operator the opportunity to stop the machine to check the upstream manufacturing process. Additionally, this system can be connected to automata or human-machine interfaces (HMIs) to automate the management of the production line.”

AI at the Service of Industry

The effectiveness of artificial intelligence depends on the volume of data used for its learning. In the case of parts analyzed by APREX, only fifty to two hundred images are needed to train the model and obtain reliable results.

“We need both compliant and non-compliant parts for supervised AI,” specifies the expert. However, depending on the complexity of the parts and the variability of defects, a larger number of images may be required.

APREX does not limit itself to a single technological approach. Its system combines several image analysis methods: supervised artificial intelligence, unsupervised artificial intelligence, and traditional parametric methods. Supervised AI allows precise naming of defects, while unsupervised AI identifies anomalies without necessarily being able to classify them.

This combination of technologies is essential in sectors that require strict traceability:

“For example, when we have automotive parts, critical safety parts, that kind of thing, we need to know the defect because this defect can help analyze production, know exactly what happened upstream, and have perfect traceability for manufacturers.”

A Complete Solution: From Software to Integration

The company offers a comprehensive solution that goes beyond just software.

“We go all the way to integration,” says George.

Indeed, the success of image analysis relies not only on a high-performance algorithm but also on suitable hardware. APREX thus determines the most appropriate camera and sensor based on each client’s specific needs. Thanks to partnerships with hardware suppliers, it also ensures the installation and integration of these devices into the client’s industrial environment.

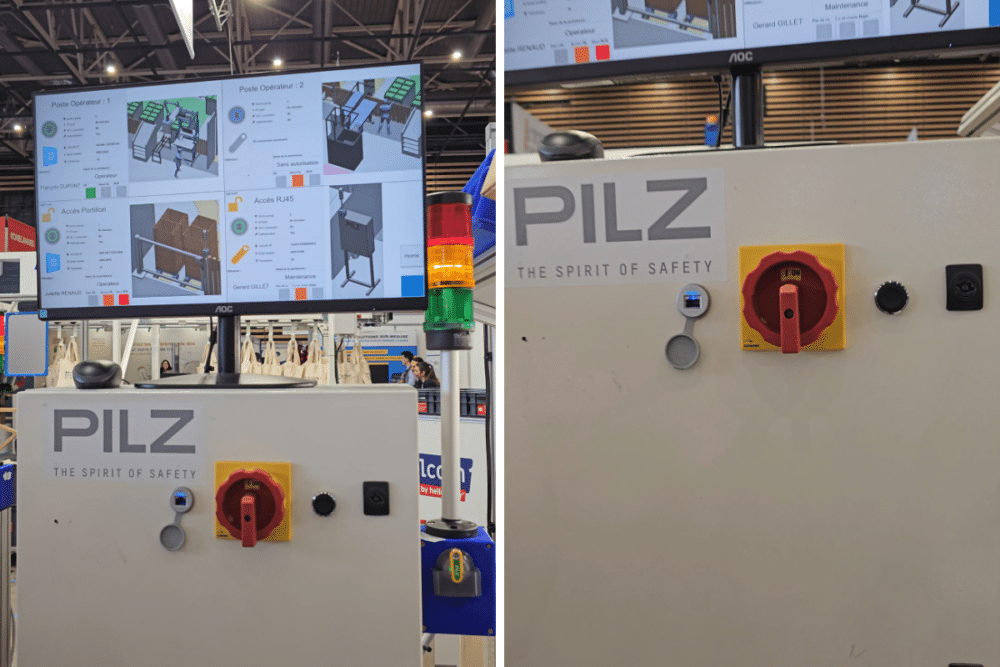

4/ PILZ: Technology for Access Management and Industrial Cybersecurity

PILZ offers an effective solution for managing access rights to industrial machines. The goal is to control who can activate a machine and under what conditions, by integrating a mode selector that manages degraded modes to ensure operational safety.

The innovation relies on a human-machine interface (HMI) that displays the different workstations. Through badges or keys, each operator can authenticate themselves and gain the necessary permissions. The system automatically recognizes the user’s identity, records access data, and provides precise control over machine usage.

Security and Control of RJ45 Ports

One of PILZ’s major advancements concerns industrial cybersecurity. A simple RJ45 port passing through a wall can pose a hacking risk, providing direct access to a company’s internal systems. To counter this threat, Pilz developed a controllable port that only activates when the user has authenticated themselves via a badge, as explained by Nicolas Desbois, Sales Engineer at PILZ:

“One of the particular innovations here is in cybersecurity. This is an RJ45, a simple port passing through a partition. The issue with these ports is that they can be hacked because I have access to all the systems if I connect. So, here we have a controllable port, meaning if I’m not authenticated, my port is not open. The benefit is to authenticate and also log who, when, and where access was granted. So, if I have access here, I have an open port, meaning I have access, but if it’s not open, and I control it, it remains closed. I’ve isolated my system.”

The benefit of this device is twofold: it allows access only to authorized individuals and ensures full traceability of connections by recording who connected, when, and where.

“This innovation meets the new regulatory requirements for industrial cybersecurity.”

PILZ is indeed anticipating regulatory evolution, particularly the machinery safety regulation that will come into effect in January 2027. This framework imposes strict measures to protect automation systems, especially regarding authentication, identification, and isolation of safety controllers.

PILZ’s controllable port fits perfectly within this framework by enabling the isolation and protection of automation systems, ensuring better control over access to critical infrastructures.

Physical Access Control to Sensitive Areas

In addition to managing access to machines and IT systems, PILZ has also developed physical locking solutions for sensitive areas. For example, to access a secured area, an operator must first authenticate themselves using a badge. Once authorization is validated, they can unlock the door and enter the secure space.

This technology can be deployed on a large scale in factories or warehouses, integrating different access levels on the same badge.

“And with one badge, I can even manage up to thirty-two different zones, with different access levels across those thirty-two zones, and in a zone where I can place multiple badge readers.”

Integration with Enterprise Management Systems

PILZ’s key and access management system relies on proprietary software. However, it can be compatible with other enterprise management systems, provided the badges used meet certain NFC standards, such as ISO 14443 or ISO 15686. This compatibility ensures a smooth integration into existing infrastructures.

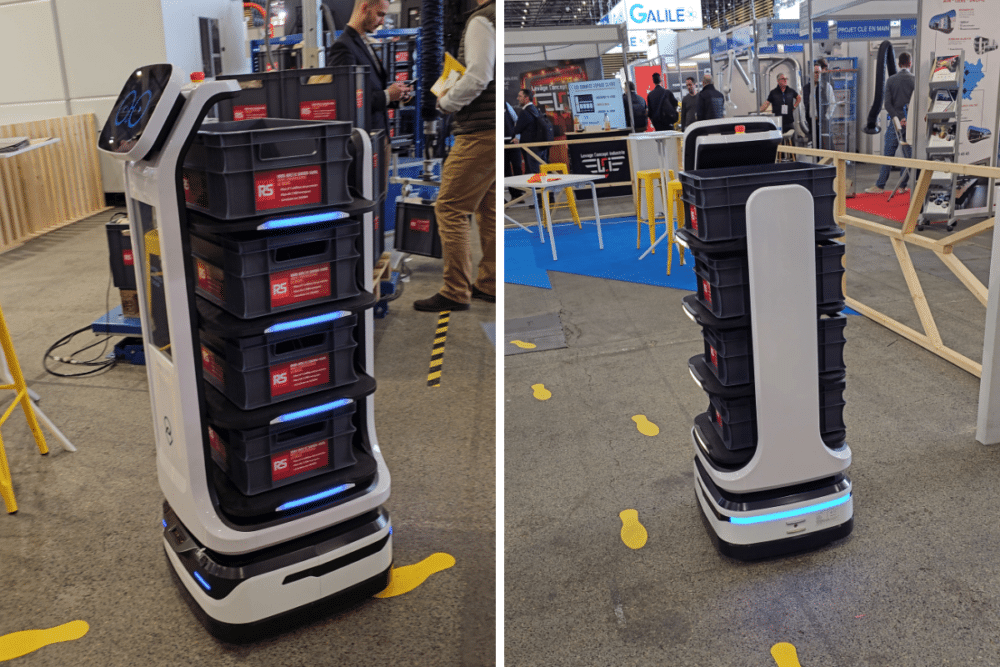

5/ Service Robots: A Revolution for Logistics and Inspection

Service robots are poised to transform many sectors, starting with logistics, by providing valuable assistance to human operators. The goal is simple: to relieve workers of physically demanding tasks by transporting items from one point to another.

Diego Lopez, Sales Manager at United Robotics Group, a distributor, explains in more detail the benefits of these robots in warehouses:

“It’s an assistant for humans, to prevent TMS (musculoskeletal disorders) related to heavy lifting, etc. The operation is intuitive. The operator places the bins or parts on the robot and, with a few clicks, sends the machine to a defined location. The robots are the ones that travel the distances and bear the weight of the loads.”

Different versions exist, capable of carrying from 40 to 600 kilograms, adapting to various industrial needs.

An Accessible and Versatile Technology

Service robots, like those distributed by United Robotics, are AMRs (Autonomous Mobile Robots) that integrate advanced technologies such as cameras and LIDAR sensors, allowing them to map their environment, identify obstacles, and navigate safely. Easy to use, they require only half a day of training to become fully operational.

Although initially designed for industry, these robots can be deployed in various sectors: hospitality, catering, supermarkets.

Inspection and Surveillance: Another Category of Robots

In addition to the service robots they distribute, United Robotics Group designs and manufactures their own inspection and maintenance robots. Unlike delivery robots, these models are intended for outdoor use and meet specific needs such as site surveillance, intrusion detection, or identifying structural problems.

Equipped with thermal cameras and other advanced sensors, these robots can detect anomalies such as fires, breaches in security barriers, or potentially dangerous conditions.

Whether for service robots or inspection robots, these technologies provide innovative solutions to improve efficiency, safety, and comfort for workers. With increasingly affordable costs and simplified use, these robots are gradually becoming indispensable tools in many sectors.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)