Our reporter Stéphanie Maingard attended the Hannover Messe Press Preview 2025, held prior to the late March to early April showcase (read her report here). There, she secured exclusive insights from Canada’s delegation and six standout exhibitors showcasing advancements in industrial technology. With a focus on Canada as the partner country, the preview highlighted groundbreaking innovations and sustainable initiatives. Here’s a firsthand look at what attendees can expect.

DirectIndustry is partnering with Deutsche Messe, Hannover Messe’s organizers. As part of our collaboration, we offer you, our readers, free tickets to the fair. Visit this page (text in French) to download your free entry!

This year, Hannover Messe, the world’s premier industrial trade fair, is set to welcome a powerhouse contingent from the partner country Canada, alongside major names in industry and emerging innovators.

With exhibitors unveiling solutions from energy efficiency to machine learning, quantum computing and AI-driven automation, the 2025 edition promises to be a crucible of industrial innovation. Given such advances, the conditions are undoubtedly ripe for a transformative showcase. This is what lies ahead for industry players.

Canada: From Flight Simulators to AI and Electric Dreams

Canada’s role as Hannover Messe 2025’s partner country signals its ambition to cement its place on the global industrial map. Christina Bilyk, A/Senior Director at Innovation, Science and Economic Development Canada, shared the nation’s enthusiasm:

“Canada is really excited because we’re a partner country this year at Hannover Messe. We’re bringing over 220 Canadian exhibitors as well as a large number of Delegates, and close to 1,000 Canadians will be in Hannover right at the beginning of April.”

This robust presence will span multiple halls, showcasing Canada’s strengths across diverse sectors. The flagship pavilion in Hall 2 will highlight the national science and innovation ecosystems, featuring R&D, clusters, startups, and quantum pioneers.

AI and Quantum Computing

Digital technologies, particularly AI, will dominate Hall 17, with heavyweights like OpenText, a world leader in Information Management, and BlackBerry, a prominent figure in intelligent software and services, that should join the fray. Bilyk emphasized Canada’s underappreciated leadership:

“Canada is very strong in AI research, and we have really interesting companies working in AI as well as our 3 well-known Canadian National AI Institutes, Amii, Mila and Vector.”

AI startups like Xanadu, a Canadian quantum computing company with the mission to build quantum computers that are useful and available to people everywhere, are expected to be a major talking point as well.

Canada’s presence at the fair will also be marked by the return of 2024 exhibitors such as RoboTape, Sarcomere Dynamics, and ZeroKey from Alberta. Innovation will be the driving force behind the Canadian showcase, as highlighted by Bilyk:

“We’ll also have CAE, which is the global leader in flight simulator production, and they’ll be showcasing some of their innovative flight simulator technology, including how it can be applied in fire zones, which is unfortunately becoming more common these days.”

Hall 7 will focus on robotics and automation engineered by Canadian firms, while Hall 13 will spotlight energy solutions, including hydrogen, sustainable manufacturing, and Electric Vehicles (EV) battery advancements.

Sustainability

Sustainability will be indeed a key pillar, with exhibitors like the global engineering firm Hatch showcasing circularity, and Eavor, a technology-based energy company that’s currently working on a geothermal project in Germany.

A standout exhibit in Hall 2, the Project Arrow Electric Vehicle, will demonstrate Canada’s end-to-end capabilities in sustainable manufacturing.

“It’s a concept car meant to showcase what Canada can do in terms of sustainability,” Bilyk noted.

She also invited global industry leaders to explore partnership opportunities through Canada’s Trade Commissioners service, set to be present at the fair. Beyond the exhibits, in Hall 12, trade and investment opportunities will be front and center for industry leaders looking to engage with Canada’s market.

For representatives of Canada, it is clear that Hannover Messe is ultimately the most important event in their economic area of bilateral relationship with Germany.

Beyond Canada, we also spoke with representatives from 6 European industrial manufacturers to learn about the innovations they will present during the trade show.

1/ igus®: Advancing Sustainable Innovation with New Product Highlights at Hannover Fair

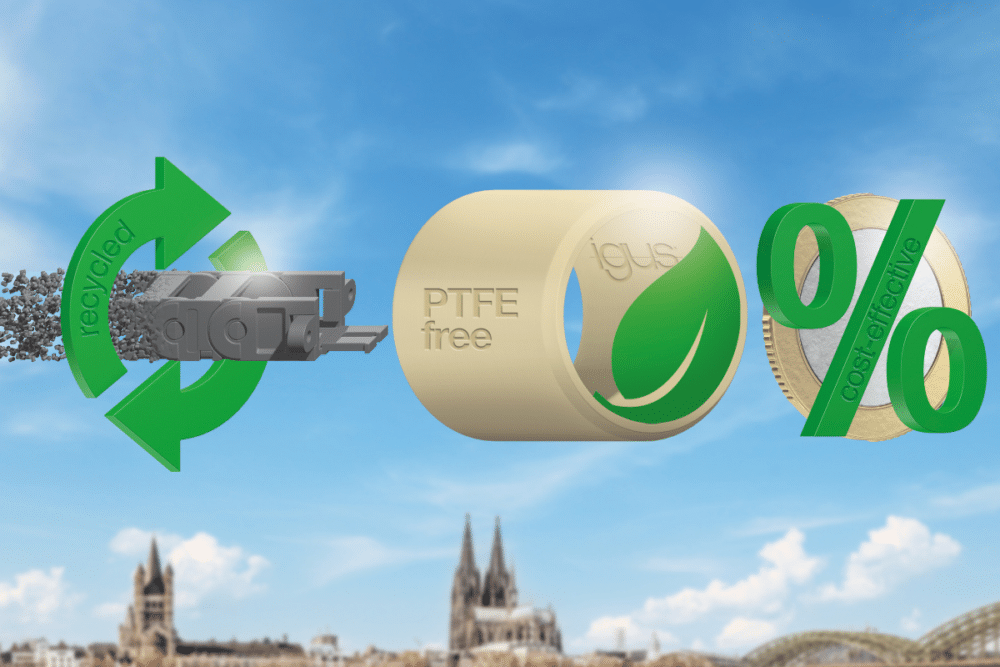

On the exhibitors front, Kira Weller, Product Manager at igus®, the famous German motion plastics manufacturer, discussed the company’s innovative solutions for sustainable movement. Specializing in Energy Chains—plastic systems that guide cables in moving applications—igus® will debut three highlights at Hannover Messe.

“We are going into sustainability without any decrease in quality or increase in price,” Weller asserted.

First innovation: In collaboration with the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, the company has developed a new certificate that verifies the cleanroom compatibility of igus® E-Chains through long-term testing, which is critical for battery production in e-mobility.

“We have done 10 months in a dry environment with a movement of 15 million double strokes, and the cleanroom class still achieved ISO class 4,” Weller said, surpassing industry benchmarks.

Second, igus® introduces PTFE- and PFAS-free materials for its iglidur bearings, aligning with potential regulatory shifts. In-house tests on friction and wear behavior show that materials with substituted PTFE outperform those containing PTFE, demonstrating the significant added value of research into alternatives.

Third, the E2 E-Chain series will transition to recycled materials, including old fishing nets, slashing CO2 emissions by 80%—equivalent to 600 tons annually—without sacrificing performance.

These innovations, launching post-fair, underscore igus®’s commitment to eco-friendly motion solutions.

Visit them in Hall 6 at Booth E26.

2/ Eco2Grow: Empowering SMEs with Green Energy

Talking about sustainability, Eco2Grow, a young German energy firm, is tackling a pressing challenge for small and medium-sized enterprises (SMEs): access to affordable, sustainable energy. SMEs have long depended on conventional approaches to secure electricity, often finding themselves at a disadvantage due to limited access to subsidized tariffs or customized business-to-business Power Purchase Agreements (PPAs).

Driven by his deep dedication, Co-founder and CEO Paul Appel outlined their mission:

“We assist industrial SMEs in lowering their energy costs and CO2 emissions by helping them procure energy directly from solar and wind farms.”

By bundling SMEs into diversified portfolios via a revolutionary fintech B2B SaaS platform, Eco2Grow unlocks PPAs typically reserved for large corporations.

Since its founding in 2022, Eco2Grow has been active in Germany, targeting industries like automotive suppliers, plastics, recycling, machinery and food production.

“What they share is that they have a certain amount of energy needs and a certain pressure to lower their CO2 emissions,” Appel said.

At Hannover Messe, he anticipates lively discussions on energy and sustainability and is looking forward to hearing how SMEs currently perceive the topic. With plans to expand across Europe, Eco2Grow’s solution, on the market since 2024, offers a scalable blueprint for decarbonizing industry.

Stop by Hall 13, Booth G71/1 to connect with Eco2Grow.

3/ Festo: The Incredible Machine Premieres at This Year’s Show

Celebrating its 100th anniversary, Festo, renowned as a worldwide supplier of automation technology and a solution provider for technical education, will unveil the “Festo Incredible Machine” at Hannover Messe, a showcase of its automation legacy based on the principle of a Rube Goldberg machine.

Sabine Lückfeldt, from Corporate Communications, described it:

“It will show the whole journey of movement in automation technology, started by the flap wing of a butterfly.”

With the “Incredible Machine,” Festo reflects on its rich history while eagerly looking ahead to the future, showcasing its passion for motion technologies—whether pneumatic, electric, digital, or a blend of these. The intricate details of this impressive machine remain a closely guarded secret, giving visitors even more reason to attend the show and witness the innovation firsthand.

Festo’s longstanding presence at Hannover Messe highlights its innovation leadership, with 8% of turnover reinvested annually. In particular, AI is a growing focus for the manufacturer, with products like Festo AX Industrial Intelligence that enables companies to gather real-time production data and analyze it using AI, and the Gripper AI which uses AI to grab any objects from trays or boxes.

Festo also ensures to prioritize customer needs in each offering.

“We find the best solution for our customer, not just considering the technology, but focusing on the optimal solution to their problem,” Lückfeldt said.

Sustainability is embedded too:

“When customers want to buy certain components, we check if it’s the right solution or if it’s too big and consumes more energy than needed. We then suggest a smaller component of the same technology that uses less energy,” she added, reflecting Festo’s holistic approach.

Get deeper insights at Hall 7, Booth A32.

4/ Siemens: Accelerating Medicine from Lab to Patient with Industrial AI

In a crisp exchange with Christoph Krösmann, Siemens Digital Industries Division’s Press Officer, the industrial titan laid out its ambitious blueprint for the future of pharmaceutical production at the coming fair.

Krösmann discussed Siemens’ unique approach to combining real and digital worlds by delivering the industrial software as well as the hardware for industrial production.

The highlight this year is a pharmaceutical production boost designed to cut the typical 10-year timeline from medicine development to patient.

“We want to help the pharmaceutical industry to accelerate this process,” Krösmann stated.

He emphasized a comprehensive strategy that spans energy-efficient buildings, digital twins for recipe development, and tech transfers for mass production. The endgame?

“More patients will have individualized medicine… a lot faster than they do today.”

Driving this efficiency is Siemens’ Industrial Co-Pilot, an AI tool built for the factory floor.

“Personnel can ask the machine about documentation of the production,” Krösmann said.

He noted its ability to assist with operations, and even coding controllers through a chatbot interface. This practical fusion of software and hardware underscores Siemens’ unique edge in combining generative AI with machine learning to optimize hardware-software synergy.

But Siemens’ vision goes beyond efficiency; it’s also courting sustainability with equal fervor:

“We’re looking at the footprint of our own products,” Krösmann said.

He then referenced to the Ecotech label introduced last year to transparently track ecological impact. By prioritizing resource-efficient production and fostering massive efficiency gains through digitalization, their products help customers evolve into sustainable digital enterprises while significantly lowering their carbon footprints.

Siemens will showcase its advancements in smart manufacturing, intelligent infrastructure, and more at Halls 8/9/13/14/15 for visitors to experience firsthand.

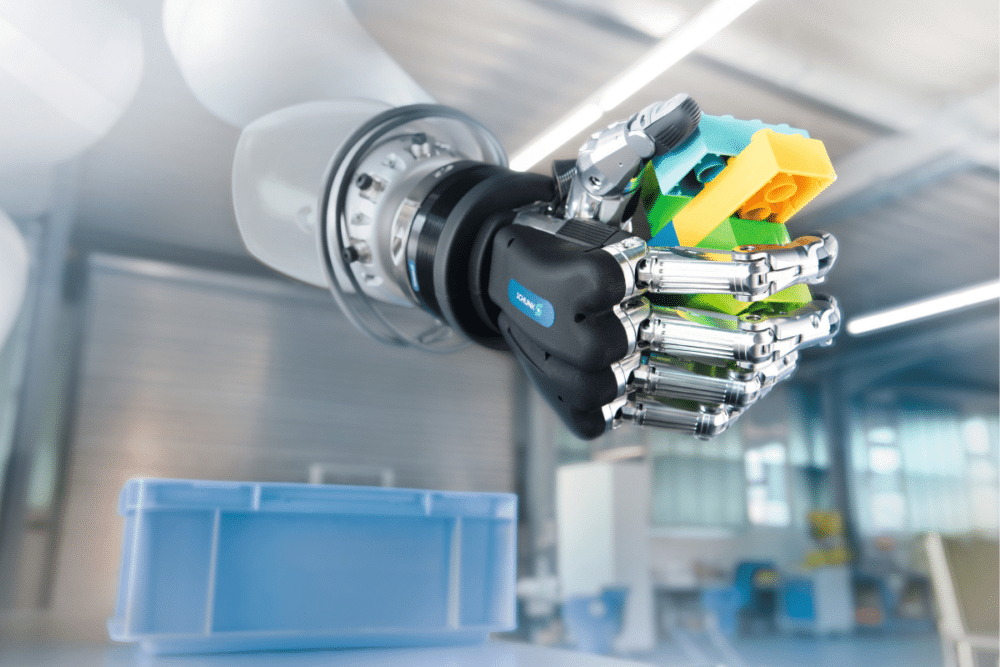

5/ Schunk: Innovative Automation for Future-Proof Production

Schunk, a leader in gripping and clamping technology, will spotlight e-mobility solutions during the fair. Patrick Engelhardt, Director of Business Development E-Mobility, highlighted their Application Pack:

“Our core focus for the Hannover Messe 2025 will be the application pack, where we will present a handling of prismatic cells from cell to pack. So we pick the cell out of a box and bring it to the module or directly to a pack. In parallel, we have in our main booth the possibility to show you a 5-finger hand application with a focus on humanoid robotics. In addition, we will also present our solution to the grasping kit. With this application, we won the Hermes Award in 2024. The grasping kit allows you to grip different parts in a box based on an Open AI configuration. So you are able to grip all the different parts directly without special programming.”

Developed with sustainability in mind alongside OEMs, these solutions target EV production—a major focus for 2025.

E-mobility being key to the energy transition and industrial transformation, Schunk has also partnered with FANUC to demonstrate automated battery production and sustainable recycling. During the fair, they will showcase automated processes for handling prismatic battery cells during discharge and feeding into a welding system.

Visitors can find this special show in Hall 6, Booth D51. Visitors can also meet Schunk at Hall 6, Booth F21.

6/ Beckhoff: Enabling a Leap in Automation Technology Performance with TwinCAT PLC++

We also interviewed Béla Höfig, from Beckhoff‘s TwinCAT Product Management, who introduced the TwinCAT PLC++, a new software product, heralding a leap in programmable logic controller (PLC) technology. Höfig described it as “the next generation of PLC technology.” First unveiled at SPS in 2024, its global release is slated for late 2025.

“It not only allows our users to have a higher runtime performance on the controller side, but also being more efficient on the engineering side,” Höfig explained, citing new editors, compilers, and runtime components.

The new compilers further optimize control code execution time, leading to a significant increase in speed. As a result, an industrial PC with lower computing power may now be enough for the previous machine control system, reducing hardware costs.

What sets Beckhoff apart is that the company integrates IT features into automation, optimizing code for speed and usability. It reduces throughput times from control development and commissioning through to the entire machine lifecycle. Aimed at a global audience, TwinCAT PLC++ promises broad applicability across industries.

Additional insights can be found at Halls 9 and 13.

For the C-suite strategists, engineers, and industry fans reading this, the message is clear: the 2025 fair promises to be a pivotal moment for the industrial sector, with Canada leading the charge and global collaborations sparking innovation across borders. Hannover Messe isn’t just keeping pace with the future, it’s forging it through the ingenuity of forward-thinkers.

Building on this momentum, the path to industrial progress is paved with both technological prowess and a commitment to environmental responsibility. Grab a front-row seat at Hannover, because this is one industrial symphony you won’t want to miss.