Automotive cable harnesses, industrial cables or appliances – the Cut & Strip Family E400 is always a great choice. High performance, optimized operability, and outstanding process reliability are the characteristics of this cut and strip machine. The intuitive S.Drive software interface facilitates job creation and boosts overall performance.

By Simone Leicht, Senior Global Omnichannel and Marketing Automation Manager at Schleuniger/Komax

The versatile and high-precision Cut & Strip Family E400 cut and strip machine is designed to meet the diverse needs of various industries. It is ideal for applications ranging from automotive and aircraft cable harnesses, industrial cables, control cabinets, household appliances, telecommunications, to consumer electronics. Its ability to process wires, tubing, ribbon, and multiconductor cables, as well as insulation materials such as PVC, PUR, and Teflon, makes it a valuable asset for any cable processing operation.

The E400 excels in standard applications, including stripping the outer jacket in multiple steps and performing full and partial strips on both ends of the cable.

Precise cable handling due to programmable contact pressure

One of the standout features of the E400 is its belt drive system with an integrated short piece kit. The feeding units with symmetrically closing clamping axis ensure precise handling of conductor cross sections from 0.14 to 16 mm² (26 to 6 AWG) and cable diameters from 0.8 to 12.5 mm (0.032″ to 0.49″).

Different feed belts and coatings of the belted rollers ensure optimal transport of cables, tailored to the material properties. The programmable contact pressure on the feeding unit allows for precise and targeted adjustments, further improving processing accuracy. All driven axes of the E400 are controlled by Schleuniger’s “Bricks” electronics platform, featuring a high-resolution cutting unit and high-precision clamping axes. The programmable gripping axis ensures accurate transport of the cable, enhancing the machine’s overall performance.

Production efficiency powered by S.Drive software

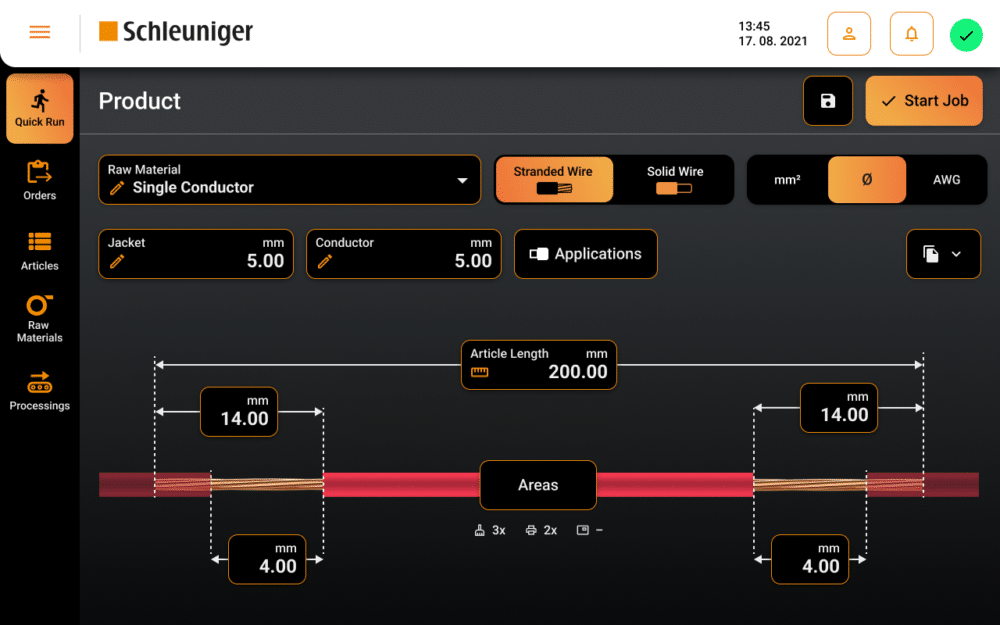

Its easy-to-learn software and efficient operation significantly reduce familiarization time. Numerous features simplify operation and boost efficiency, including predefined and verified default parameters for quick job creation, a “Quick-Run Mode” for immediate production, and an intuitive interface for easy job and article program creation.

The S.Drive software, running on all new-generation Schleuniger Cut & Strip machines, minimizes commissioning and operator training costs. The software guides the operator through setup and troubleshooting, providing information on the HMI, minimizing downtime, and ensuring continuous productivity.

Built with proven operational reliability and a high level of convenience, the E400 features an ergonomic design and a modern, clear human-machine interface (HMI). The 10-inch color touchscreen display functions in a neatly arranged manner, focusing on essential parameters and user-friendly operation.

The high-quality finish and materials used in its construction guarantee durability and long-term performance.

Expandable at any time according to your needs

The E400 offers a wide range of options for superior process quality. The basic version can be customized with software upgrades and additional equipment to meet specific needs. Options include a cable jam detector, marking function for printing or labeling, swivel guides matched to cable diameter, V-shaped and radius blades for various applications, and different belt materials for roller and drive belts. A toolbar with a magnetic holder for key swivel guides and other accessories is also available.

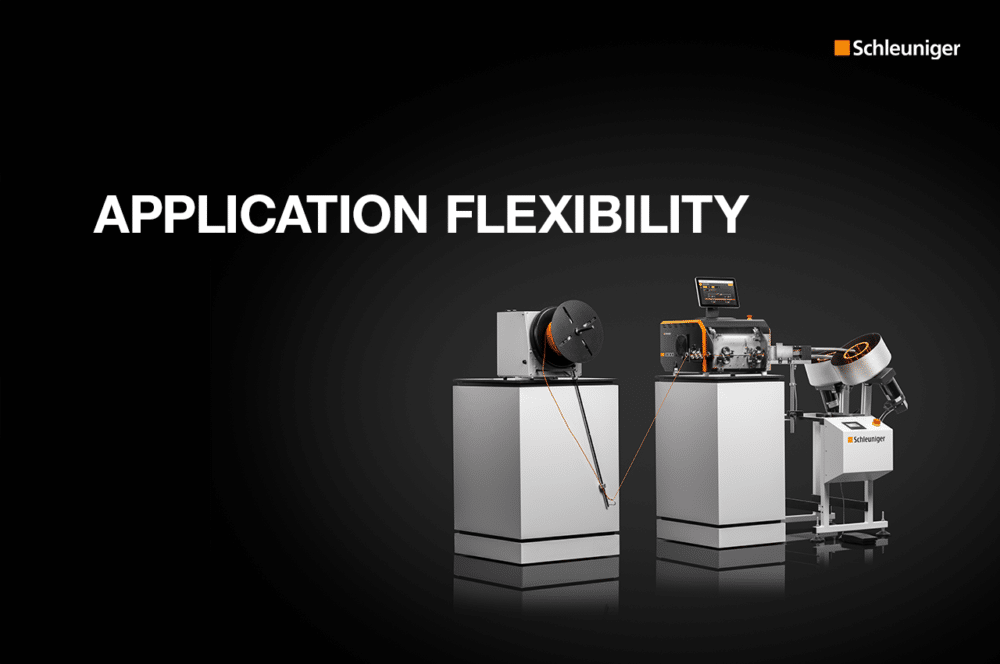

The E400 Cut & Strip machine can be combined with many peripherals to set up automatic processing lines. Existing Schleuniger peripherals are compatible, allowing for processes such as feeding, marking, hot stamping, and coiling. This flexibility ensures that the E400 can adapt to evolving production requirements, ensuring a future-proof investment for any cable processing operation.

The compatibility of blades, belts, and guides with the predecessor model, MultiStrip 9480, allows for seamless integration and upgrades, maximizing the utility of existing equipment.

The E400’s standardized interfaces allow for the reuse of existing connection cables and stock parts, making it a cost-effective solution.

![Image [Best of 2025] Power Moves in the Energy World](/wp-content/uploads/sites/3/energy-320x213.jpg)

![Image [Best of 2025] How Generative AI Is Transforming Industry](/wp-content/uploads/sites/3/AI-4-320x213.jpg)

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)