As electric mobility rises, the importance of sealing systems in electric vehicles (EVs) becomes increasingly critical. Beyond sealing of the battery pack, Hutchinson is providing a full range of sealing solutions for other applications related to EVs challenges, from gasketing to components of thermal management, E-Powertrain and acoustic insulation.

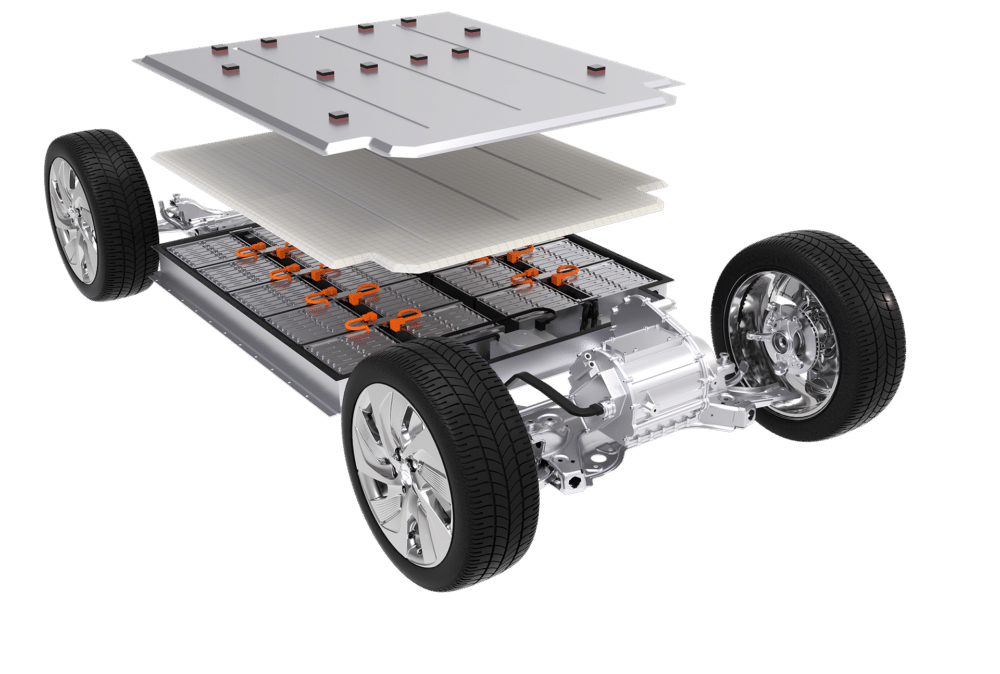

High performance Solutions for Battery Packs

Battery sealing is a major challenge for automakers, requiring protection of the pack against moisture or dirt, and against fire in case of thermal events.

Hutchinson material expertise has enabled to launch a new fire-resistant EPDM material, specially designed for battery pack seals and cooling circuit seals. Certified UL94 V0, it offers superior sealing, improved chemical compatibility, and excellent low-temperature performance, all while being halogen-free for enhanced safety and durability.

Hutchinson designs and manufactures battery casing seals with exceptional resistance to fire and high temperatures. Using high-quality materials, gaskets withstand extreme conditions without compromising integrity. They provide excellent sealing, protecting the battery pack’s internal components and extending battery life.

With engineered materials, Hutchinson also delivers innovative technologies to contribute to higher energy efficiency, performance, extended autonomy and safety for batteries.

Composite spacers protect the top cover from transportation and vibrations. They ensure the air gap between the battery pack cover and the car body in case of thermal runaway.

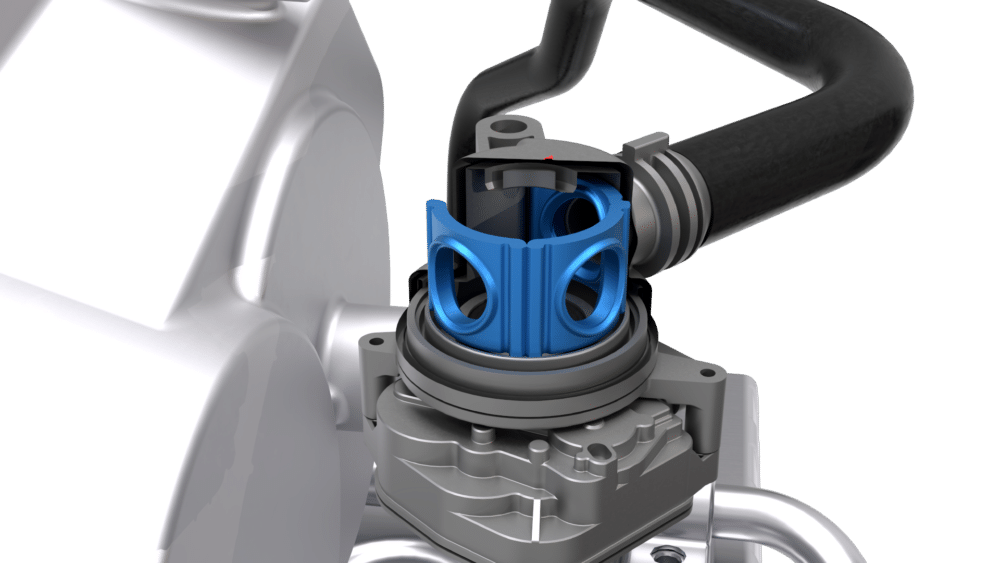

Advanced Thermal Management

Our innovative systems provide optimized thermal management for BEV’s, ensuring energy efficiency, comfort and safety in harsh conditions, meeting the industry’s growing demands.

We have developed sealing solutions for Multiway Valves and modules. Low friction sealing pads offer high sealing performance on a wide range of temperature and pressure, and low wear over complete lifetime. Lip seals (Y-Rings or X-Rings) for dynamic rotative shafts feature increased resistance to wear and low assembly force.

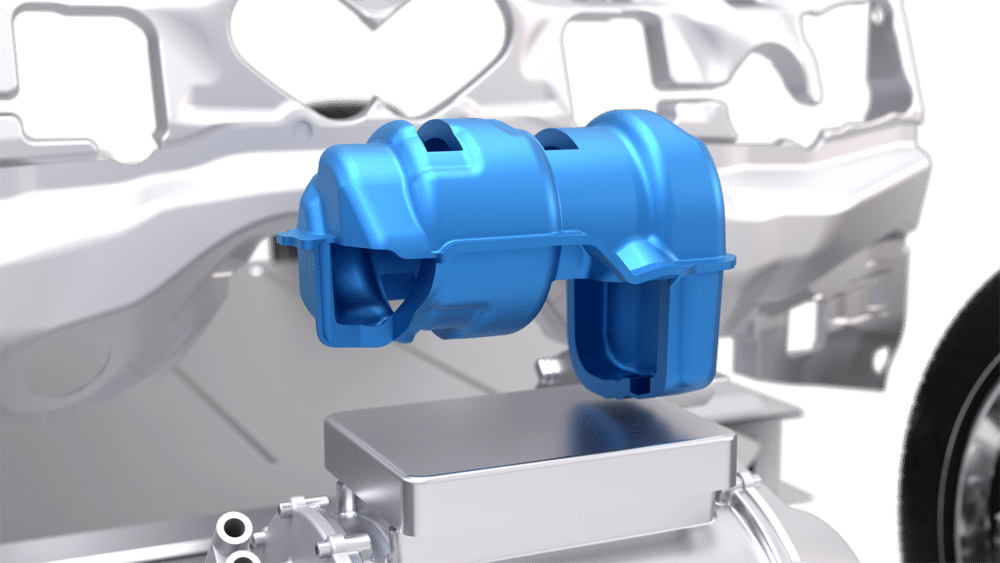

Our solutions for thermal management also include Slimline Sealing washers for HVAC connectors with easy assembly and high resistance to very high pressure, air ducts for HVAC applications and battery thermal management. NVH encapsulation contributes to improving thermal insulation of the cooling compressor.

Enhanced Acoustic Insulation

Cabin noises can arise from multiple sources and occur while the vehicle is on the move, stopped or parked, especially during the fast charge. This leads OEMs and equipment suppliers to search for new ways to address noise pollution challenges while respecting new insulation regulations.

Expert in sealing and insulation technologies, specialized in the production of high-quality hush panels and acoustic solutions, Hutchinson has designed an innovative multi-layer cover with advanced acoustic properties for electric & hybrid vehicles. This NVH (noise vibration, harshness) encapsulation solution offers an excellent combination of vibration attenuation and absorption, especially at high frequencies (>1000 Hz), attenuating the noises of cooling compressors and e-motors.

Powertrain Solutions

Electric powertrains present significant challenges in terms of energy efficiency, thermal management, durability, and reliability. Our multiple expertise enables us to design high performance solutions for E-powertrain, extending service life, reducing size and weight, and improving passenger comfort and safety.

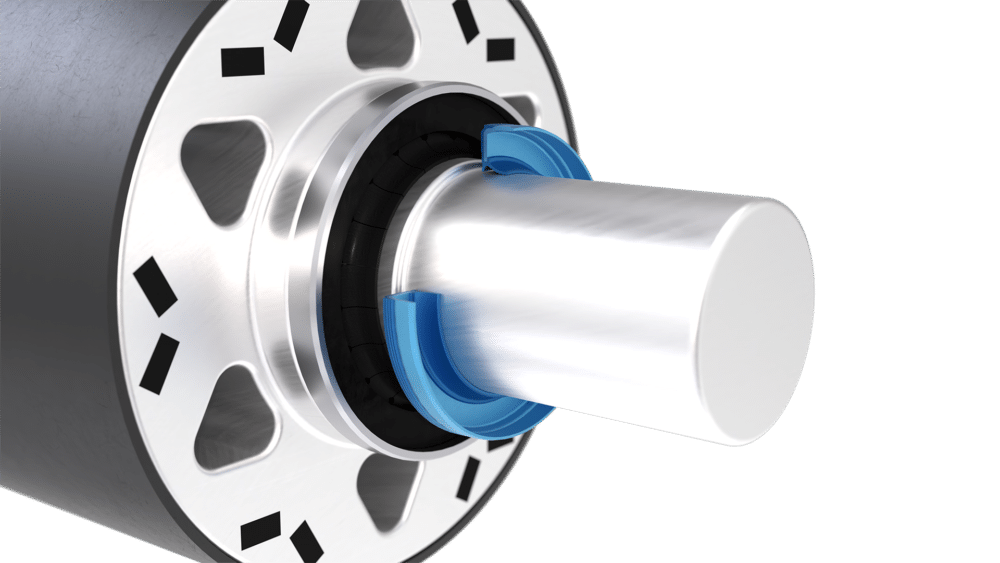

Our high-performance conductive ring is designed to divert electrical currents from bearings and prevent electronic interference. This ring features high electrical conductivity, low friction, and robust durability under mechanical stress, with a compact design for easy integration into various electrical systems.

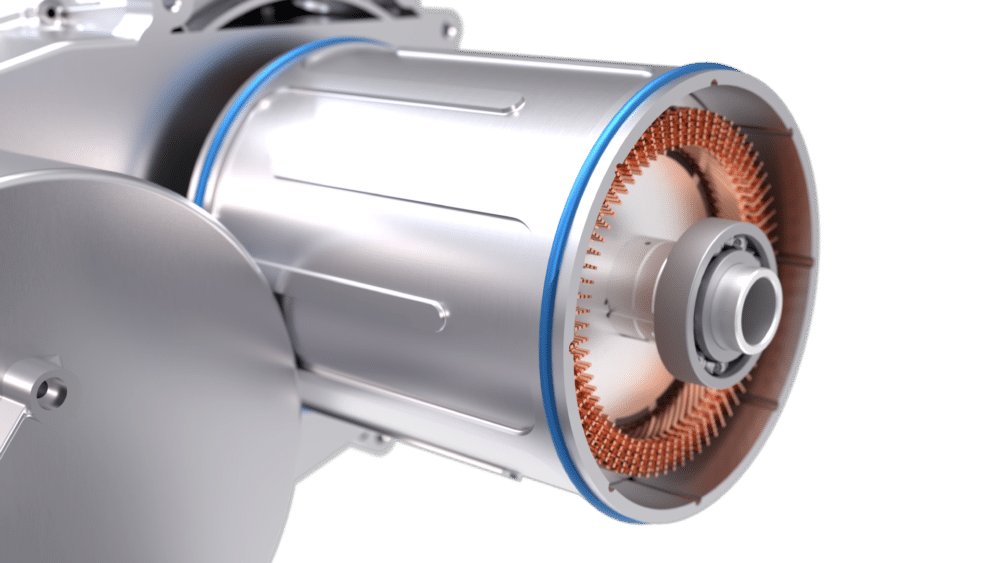

Oil spray rings facilitate the circulation of the dielectric cooling fluid and therefore play a key role in cooling electric motors. By continuously and precisely spraying oil directly onto the copper windings, heat is quickly dissipated. Our oil spray rings guide the fluid for rapid cooling, while sealing the electric motor.

Ensuring reliable sealing is essential to extend the product’s lifetime. Plate seals, with their rigid backing that act as a spacer for fixing screws, withstand high temperatures and intense pressure, and are approved for automotive applications, particularly EVs.

XL O-Rings match E-motos large diameters while offering chemical resistance against coolants, transmission oil and dielectric fluids.

High speed shaft seals have been optimized to cope with E-powertrains requirements: higher rotation speed, low friction, and reverse gear.

By working closely with vehicle and equipment manufacturers, Hutchinson continually pushes the boundaries of technology to offer high-performance solutions to the challenges of electric mobility: energy efficiency, performance, battery durability, safety, and passenger comfort.

Its deep expertise in materials and tailormade design enables Hutchinson to provide optimal sealing, fire protection, acoustic and thermal insulation for carmakers and Tier 1 / Tier 2 manufacturers.