DirectIndustry, in partnership with JETRO, Japan External Trade Organization, presents a selection of high-quality industrial products from the top Japanese manufacturers. In this article, we focus on the products of 6 Japanese manufacturers.

JETRO, an institution under the Japanese Ministry of Economy, Trade and Industry, fosters economic relations between Japan and the world. It supports innovation through direct investment in Japan and assists Japanese companies in expanding globally.

DirectIndustry, powered by VirtualExpo Group, a specialist in online exhibitions, provides Japanese manufacturers with a platform for showcasing their products. Over 2,000 products are displayed at the VirtualExpo Japan Pavilion in industry, healthcare, architecture, and more sectors.

This article provides a collection of products by 6 industrial manufacturers in various sectors including measurement, and electronics.

1/ Kyokko Seiko Co., Ltd.: Precision Equipment

Kyokko Seiko Co., Ltd. is a Japanese company established in 1944 that manufactures precision equipment. They focus on factory automation machines, office equipment, and medical equipment.

Their new Microfilm Scanner SL1000 Q represents a leap forward in microfilm digitization technology. It is designed to enhance efficiency and usability across various applications. Known for its compact size and lightweight build, this scanner connects seamlessly to PCs. It allows users to zoom in on digitized images displayed on monitors.

Building on the success of its predecessor, the SL1000, which set a global standard as the first screenless microfilm scanner with over 2,600 units sold worldwide, the new model was developed to meet growing demands for enhanced functionality and ease of use.

Key features of the new scanner include a blip detection function for precise image capturing and quiet operation, ensuring minimal disruption in library and educational settings. It is equipped with a dedicated application tailored to streamline microfilm digitization processes, optimizing workflow efficiency.

The scanner has gained significant traction in national institutions like the National Diet Library and the National Archives of Japan, where over 70 units have been deployed. Internationally, it has seen export to more than 220 units, contributing to the global effort of microfilm digitization. With cumulative sales exceeding 410 units, this scanner continues to be a preferred choice for institutions seeking reliable and efficient solutions for digitalizing microfilm archives.

2/ Koyo Giken: A New Generation of Spot Welders

What images come to mind when you hear the word “welding”? A protective mask shielding eyes from intense light, craftsmanship amid sparks, or a soldering iron from a school class might be your initial thoughts. However, modern welding technologies at manufacturing sites today have dramatically evolved, significantly improving productivity. For the past half-century, Koyo Giken has been developing technologies that enable anyone to weld metals safely, quickly, and with high quality.

Koyo Giken was founded in 1976 by a group of mechanical design professionals and manufactures table spot welders. With nearly 3000 units sold in Japan and 25 countries, Koyo Giken has established itself as a trusted name in the industry.

Traditional welding preparations require many people and considerable time to ensure stability and safety. Their table spot welder, MYSPOT, revolutionizes this process by allowing a single person to perform welding safely and at a higher speed. Simply place the material on the table, select the material type and plate thickness, and you can start welding immediately.

A common issue in welding is the variability in quality depending on the welder’s skill. Burn marks, blackened spots, and distorted welds often necessitate secondary processing. Their high-speed welding technology ensures that anyone can achieve consistent, high-quality results, even with large workloads. No burn marks or distortion occur, and finish polishing to smooth the welded part is unnecessary. Their technology guarantees a high-quality finish with no variations in strength or appearance.

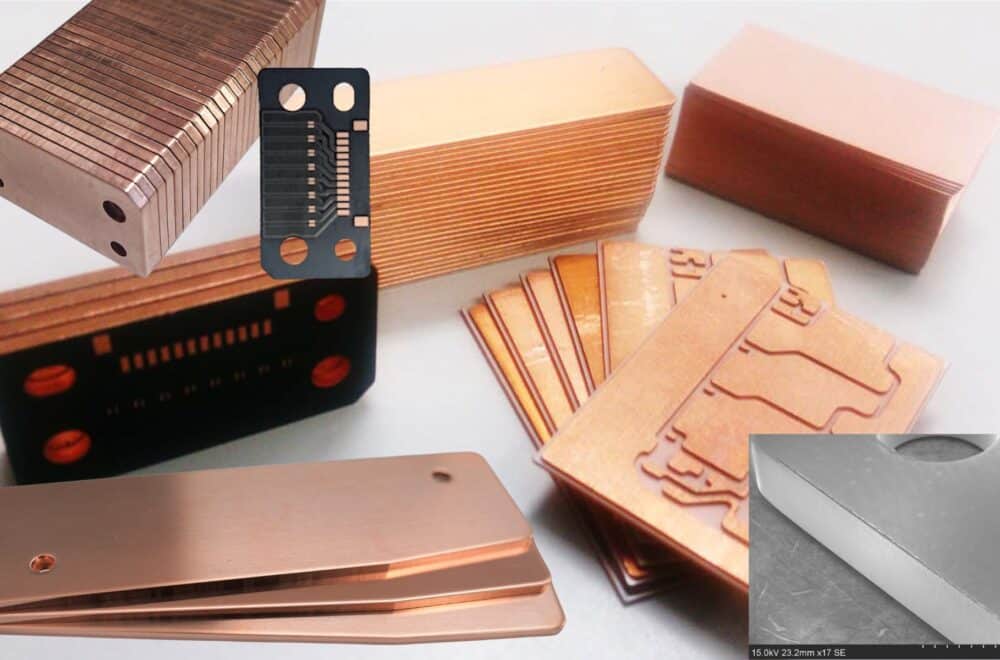

3/ Sanko Giken: High-Precision Punching

Based in Osaka, Sanko Giken specializes in high-precision punching, such as aluminum punching.

With 45 years of expertise, they offer a diverse range of services. These include ultra-precise positioning with robotic-assisted presses, fine blanking, and laser cutting.

The company is accustomed to handling large-scale production, with a track record of over 100 million IC cards and monthly outputs of 3 million heat dissipation substrates.

Additionally, they are capable of working with various materials, including special materials and large formats.

4/ TEAC Corporation: Measurement Products

Since its foundation in 1953, by integrating recording technologies with the remarkable advances being made in communication technologies, TEAC is steadfastly meeting the challenges of developing high-quality technology, products, and services that customers demand.

Data Recorder Business

TEAC’s data recorder business focuses on recording, analyzing, and diagnosing physical signals. This includes Vibration, noise, strain, pressure, and CAN (Controller Area Network) signals, Wideband multi-channel data recording, Solutions for transportation equipment, power generation facilities, and production equipment.

Load Cell & Transducer Related Businesses

TEAC provides load cells compatible with various semiconductor manufacturing equipment. Their product lineup includes compact, high-precision, and low-capacity load cells. Additionally, TEAC offers a load management system that supports worldwide applications.

This system promotes various Fieldbus-compatible signal conditioners and digital indicators with multilingualization, and TEDS (Transducer Electronic Data Sheet) Plug & Play.

The functions included in the indicator are:

TEDS (Transducer Electronic Data Sheet) is a function that simplifies sensor setup by automatically configuring the measurement system based on the connected transducer. It stores essential information about the transducer, such as calibration data, sensitivity, and manufacturer details.

CC-Link is an open-field network for industrial automation, enabling communication between devices in manufacturing processes, including sensors, controllers, and actuators.

EtherNet/IP™ is an industrial communication protocol based on standard Ethernet. It allows seamless integration of devices across different manufacturers and facilitates real-time control and data exchange.

5/ Orbray: DC Coreless Motors

Orbray Co., Ltd. is a Japanese manufacturer specializing in DC coreless motors. Among their products are the dyNALOX No Electricity Locking System and the Diaphragm Pump.

The dyNALOX No Electricity Locking System is designed to transfer torque from the input shaft to the output shaft while locking rotation from the output shaft. This prevents torque transfer from the outside to the inside, even under no-power conditions.

By adding a few extra millimeters on top of a planetary gear, the motor remains locked against external forces.

The system eliminates the need for a low-efficiency reduction system (such as a worm gear or slide screw). It also contributes to a smaller system size.

It operates without electric power, which helps reduce current consumption and provides an emergency stop function.

Applications include robotics, roll curtains, and sliders.

The Diaphragm Pump features self-designed check valves that optimize contact pressure between the diaphragm and a stage. This ensures stable self-priming and flow characteristics.

These pumps excel in corrosion resistance and are made with internal parts specifically selected based on the fluid used.

They find applications in cutting-edge fields such as cell separation, 3D printing, industrial printing, life sciences, and new production processes.

6/ Xacti: Digital Imaging Solutions

Xacti Corporation is a Japanese company that specializes in digital imaging solutions. The company’s products include wearable cameras and AI-processed dashcams for construction machinery.

The company’s products are designed for harsh environments and workplaces. Their proprietary IC image processing ensures blur-free images, durability, and reliability. The wearable cameras can be connected to a smartphone for real-time video sharing. Users have praised their powerful image stabilization and horizontal functions for making the videos very easy to view.

Xacti Corporation also offers drone cameras that provide aerial imaging solutions for various industrial applications.

Xacti provides cameras that match various industries with edge AI technology based on its proprietary IC and image processing technology with over 30 years of experience.

![Image [BUYING GUIDE] How to Choose the Right Industrial Robot?](/wp-content/uploads/sites/3/Industrial-Robot-320x213.jpg)

![Image [Buying Guide] How to Choose the Right Safety Shoes?](/wp-content/uploads/sites/3/Safety-Shoes-320x213.jpg)

![Image [Buying Guide] How to Choose the Right AMR?](/wp-content/uploads/sites/3/AMR-320x213.jpg)